Grout plant for ground anchor grouting

Grout plant for ground anchor grouting applications: Ground Anchor Installation: Reinforcing soil or rock around tensioned anchors in deep excavations, retaining walls, or slopes. Soil Nailing: Stabilizing slopes or excavations by injecting grout around steel bars. Tunneling: Pre-grouting to seal water inflows or stabilize surrounding rock. Foundation Underpinning: Strengthening weak soils beneath existing structures. Mining: Rock bolting and ground support in underground mines.

A grout plant for ground anchor grouting is a specialized piece of equipment designed for efficiently mixing and pumping grout for the installation and stabilization of ground anchors. These anchors are crucial in geotechnical engineering projects for reinforcing slopes, retaining walls, bridges, and tall structures.

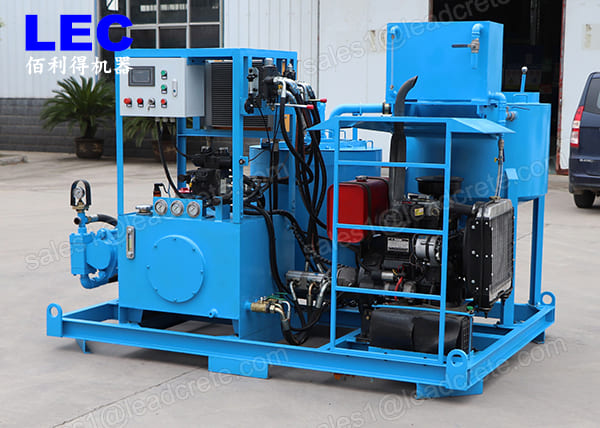

Today we shipped 1 frame grouting pump plant to our customer. The following is a display picture of our factory:

The parameters of this grouting pump plants are as follows:

| Model | LGP350/800/70PI-E Grout plant for ground anchor grouting |

| Dimensions | 2590*2100*1980mm |

| Weight | 1950kg |

| Mixer | |

| Capacity | 350L |

| Output | 5m3/h |

| Suitable water/cement ratio | ≥0.5:1 |

| Motor Power | 15KW |

| Rated Rev. | 1450rpm |

| Agitator | |

| Capacity | 800L |

| Motor model | 1.5KW |

| Rated Rev. | 35rpm |

| Pump(hydraulic twin-cylinder) | |

| Output | 0-70L/min (70L/min, at 3Mpa) |

| Pressure | 0-7Mpa |

| Power | 15KW |

Here’s a breakdown of what a grout plant for ground anchor grouting typically entails:

Preparation of Grouting Materials: Accurately mixes cement, water, and often additives (like bentonite or sand) into a homogeneous grout slurry according to a specific formula. Some plants use high-shear colloidal mixers for rapid and thorough mixing, even with low water-cement ratios.

Grout Material Delivery: Equipped with a robust pumping system to deliver the prepared grout to the anchor borehole. This system needs to maintain consistent flow and pressure to ensure the grout evenly fills the gaps around the anchor, creating a strong bond with the surrounding soil or rock.

Pressure Control: Provides precise control over the grout injection pressure, which is vital for ensuring proper penetration and preventing damage to the surrounding ground or the anchor itself.

Continuous Operation: Many grout plants offer continuous mixing and pumping capabilities to ensure an uninterrupted supply of fresh grout during the entire anchoring process.

Related applications of grout plant:

Ground anchor / Rock bolt grouting

Micropile / Soil nailing injection

Post-tensioning duct grouting

Tunnel & shaft stabilization