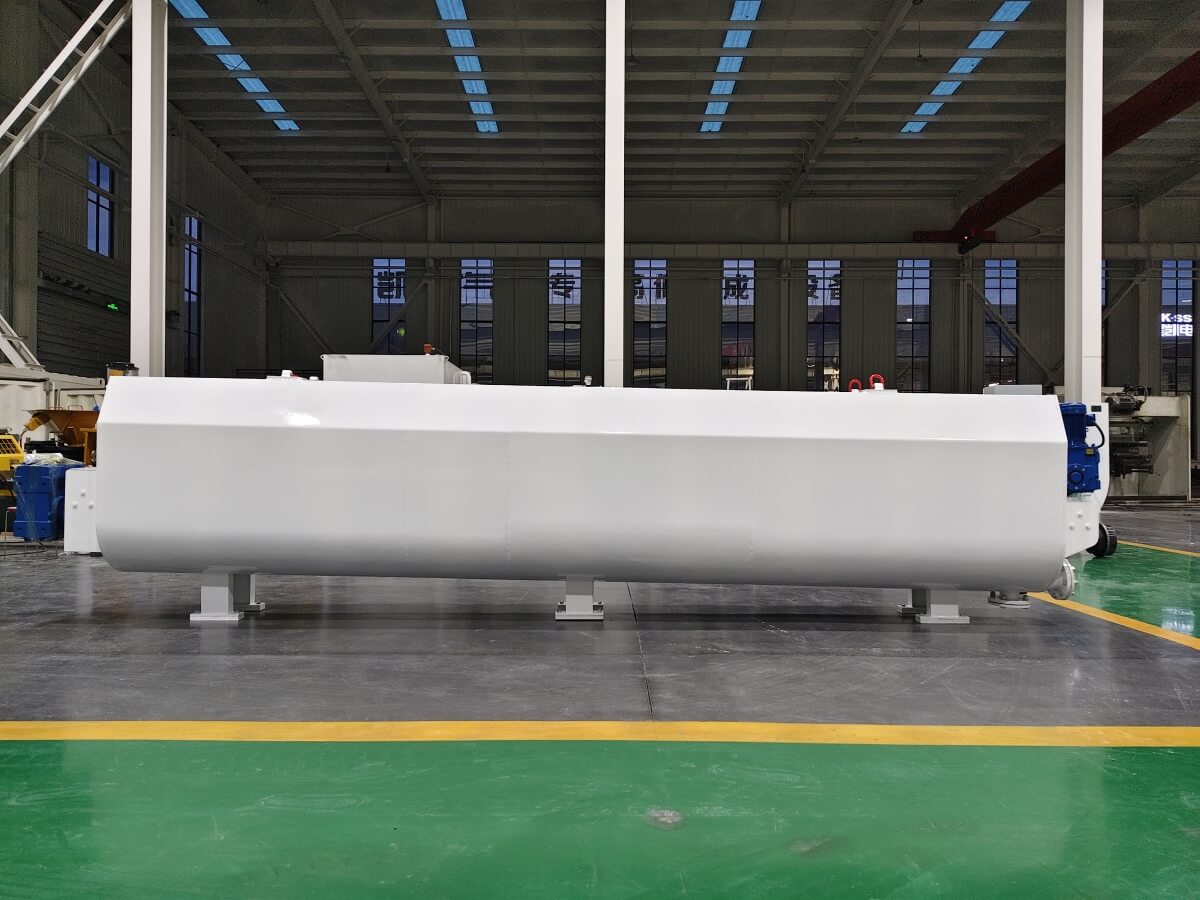

Hose concrete pump with mixer

Hose concrete pump with mixer is an engineering machinery that integrates concrete mixing, pumping and hose transportation. It can achieve flexible material distribution at the end through the hose, which is suitable for narrow spaces or construction scenes that require manual assistance. Its core functions include:

Integrated mixing and pumping: Mix concrete on site and pump it directly, reducing intermediate links and improving efficiency.

Flexibility of hose distribution: The rubber hose at the end can be swung manually, which is suitable for small-scale paving or pouring in complex terrain.

Multi-scenario adaptability: It is widely used in rural house construction, municipal engineering, road repair and narrow site construction.

Hose concrete pump with mixer is an engineering machinery equipment that integrates concrete mixing, pumping and hose conveying functions. Its core working principle is:

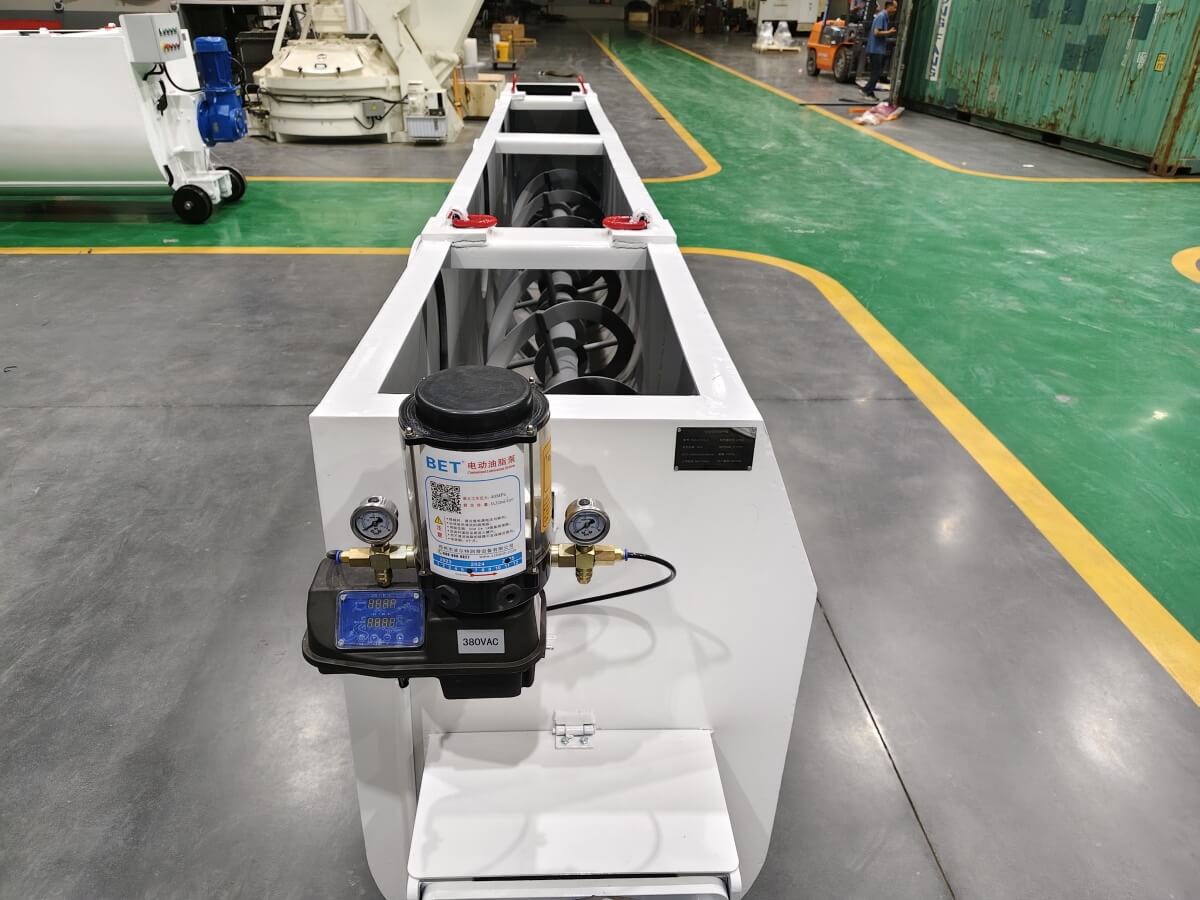

Extrusion conveying: By mechanically squeezing the flexible rubber hose, the concrete in the pipe is subjected to pressure difference to achieve continuous pumping. The hose is arranged in a U shape in the pump body, and the squeezing roller rolls along the surface of the hose, gradually compressing the hose cross section and forcing the concrete to flow toward the outlet.

Integrated mixing: The equipment is equipped with a forced mixing device, which can mix concrete on site to ensure material uniformity and reduce the risk of segregation.

Flexibility of hose: The rubber hose at the end can be swung manually to adapt to narrow spaces or complex terrain casting, such as small-scale paving, slope tops, curved balconies, etc.

Technical features and advantages of hose concrete pump with mixer:

Simplified structure and cost optimization

No complex valve body: Compared with piston or S-valve pump trucks, the squeeze pump truck omits vulnerable parts such as distribution valves and glasses plates, reducing maintenance costs.

Easy hose replacement: As a core consumable, the hose has a long replacement cycle and low cost, which is suitable for high-frequency construction scenarios.

Adaptability and flexibility

Applicable to narrow sites: The hose can be inserted into trenches, holes or indoor operations, reducing the distance of manual handling.

Advantages of small-batch construction: The single pumping volume is controllable, suitable for small-scale projects such as rural house construction and municipal repairs.

Sealing and durability

Dynamic sealing compensation: Some designs automatically compensate for the wear of the inner wall of the hose through variable pads, restore the sealing function, and extend the life of the hose.

Application of wear-resistant materials: The hose lining adopts a high-wear-resistant rubber layer, the outer layer is covered with an aging-resistant rubber layer, and the reinforcement layer adopts a cord layer or a wire rope winding layer to improve pressure resistance and durability.