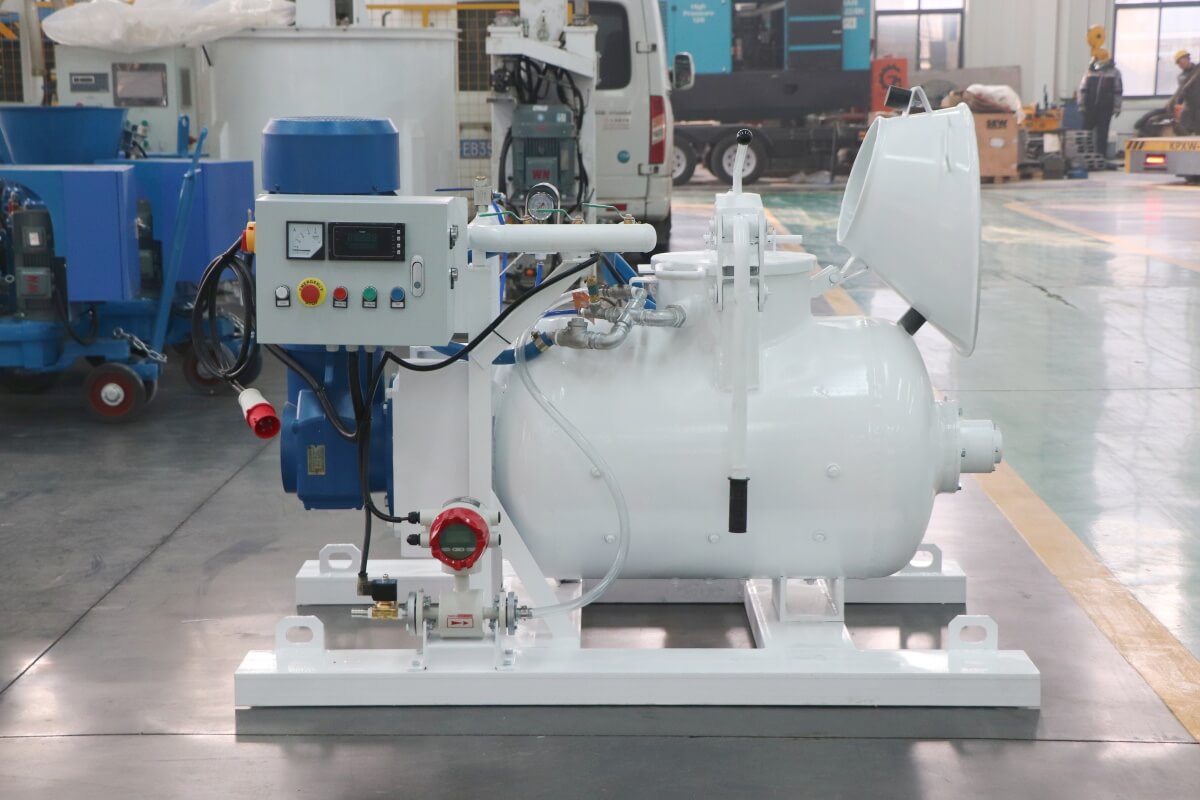

Refractory concrete spraying pump

The refractory concrete spraying pump uses a hydraulic or pneumatic system to deliver dry-mixed refractory materials (such as refractory castables and spray coatings) to the spray gun, where they are mixed with high-pressure water or air and sprayed onto the work surface. Its core principles include:

Dual-cylinder alternating feeding: Similar to a dual-cylinder piston engine, one cylinder draws material while the other pushes it, achieving continuous and uninterrupted spraying and ensuring stable pressure.

Hydraulic drive: A hydraulic pump provides power to drive the piston in reciprocating motion, adapting to the delivery of high-viscosity, high-density refractory materials.

S-tube distribution valve: Automatically compensates for wear gaps, providing excellent sealing performance and reducing the risk of grout leakage and pipe blockage.

Wear-resistant design: Key components (such as spectacle plates and cutting rings) are made of wear-resistant alloy materials, extending their service life.

I. Overview of Refractory Concrete Spray Pumps

Refractory concrete spray pumps are specialized construction equipment designed for high-temperature industrial environments. Their core function is to efficiently transport and precisely spray refractory concrete, providing stable support for the construction and maintenance of linings in critical industrial equipment such as furnaces, kilns, and boilers. Within modern refractory construction systems, this equipment holds a central position, with its performance directly determining the construction quality, service life, and the continuity and safety of industrial production for refractory linings.

In high-temperature industrial sectors such as steel, cement, power generation, and non-ferrous metal smelting, equipment linings must endure prolonged exposure to extreme temperatures, material abrasion, thermal shock, and chemical corrosion. Consequently, the reliability of refractory construction is critically important. Refractory concrete spraying pumps, leveraging their unique construction advantages, have become critical equipment for ensuring construction quality in such demanding scenarios.

II. Fundamentals of Refractory Concrete

Refractory concrete is a high-temperature composite material primarily composed of refractory aggregates, binders, admixtures, and water mixed in specific proportions. Aggregates determine high-temperature resistance and abrasion resistance, binders ensure strength, while admixtures optimize construction and service properties (e.g., improving workability and enhancing thermal shock resistance).

Industrial applications demand four core properties from refractory concrete:

– High-temperature stability (structural integrity under prolonged heat)

– Abrasion resistance (withstanding material erosion)

– Thermal shock resistance (crack prevention during rapid temperature changes)

– Chemical stability (resisting flue gas and molten material corrosion)

Industrial refractory concrete is categorized into three types: low-cement (high-temperature resistant, suitable for medium-to-high-temperature furnace linings), ultra-low-cement (superior high-temperature and corrosion resistance, used in critical high-temperature areas), and corundum-based (featuring corundum aggregate for exceptional performance in extreme high-temperature environments).

The unique characteristics of refractory materials necessitate specialized spraying pumps: First, the presence of hard aggregates and high abrasion resistance causes rapid wear on standard pump components. Second, the high viscosity and poor fluidity require specialized pump bodies to deliver sufficient pressure, ensuring smooth and uniform transportation and spraying.

III. Working Principle of Refractory Concrete Spray Pumps

Core Principle: Through the synergy of mechanical power and pneumatic pressure, these pumps complete the entire process of refractory concrete mixing, conveying, and spraying. This involves proportionally blending materials, pressurizing them within the pump body for delivery to the construction site, and atomizing them through a nozzle to form a dense refractory lining.

Core Components and Functions: Mixing System (forced agitation ensures uniform blending of high-viscosity materials); Pumping System (screw pumps handle wet materials with stable flow; piston pumps deliver high pressure and long-distance delivery, accommodating diverse materials); Spray Nozzle (adjusts direction and atomization to enhance efficiency and adhesion); Air Compressor (provides stable air pressure for uniform coverage and clog prevention).

Continuous mixing and delivery constitute its key feature. Automated control enables uninterrupted operation, eliminating traditional segmented mixing and manual transfer processes. This enhances construction efficiency while ensuring consistent material properties and stable lining quality.

To guarantee stable material flow and uniform spraying, the equipment incorporates multiple optimized designs:

– Variable frequency speed control in the pumping system adapts to construction demands;

– Wear-resistant treatment on pipeline inner walls reduces friction;

– Pressure regulation devices on nozzles prevent thickness inconsistencies; High-end models incorporate flow monitoring feedback systems that trigger alarms and adjustments during anomalies.

IV. Types of Refractory Concrete Spray Pumps and Their Applications

4.1 Wet Refractory Concrete Spray Pump

The wet refractory concrete spray pump operates by first thoroughly mixing refractory materials with water in a mixing system to form a wet slurry. This slurry is then conveyed through the pumping system along pipelines to the nozzle, where compressed air completes the spraying process. Because materials are pre-mixed uniformly, the wet spraying process effectively ensures consistent material performance.

Its core advantages include: low material rebound rate (typically only 5%-10%), significantly reducing material waste; high density and low porosity of the sprayed lining, offering superior high-temperature resistance and erosion resistance; strong material adhesion, forming a robust bond with the substrate to effectively extend lining service life; reduced dust generation during construction, creating a more environmentally friendly working environment and lowering health risks for operators.

Typical applications include: ladle lining construction in the steel industry with high quality requirements, high-temperature zone lining pouring and maintenance in rotary kilns within the cement industry, and boiler furnace wall lining construction in the power generation sector.

4.2 Dry Refractory Concrete Spray Pump

The dry refractory concrete spray pump operates in contrast to wet spraying. It first conveys dry refractory powder through delivery pipes to the nozzle, where a water-adding device uniformly mixes water with the dry powder. Finally, compressed air propels the mixture to the construction site. This process eliminates the need for pre-mixing wet materials and features relatively simple equipment structure.

Its core advantages include: high operational flexibility, allowing real-time adjustment of material ratios and spray volume based on construction needs; extended delivery distances, with horizontal reach exceeding 50 meters and vertical reach surpassing 20 meters, making it suitable for long-distance applications in large industrial furnaces; Lightweight equipment facilitates easy mobility, making it particularly suitable for temporary construction in remote or field locations; Strong adaptability to construction environments ensures normal operation even in dry, windy conditions.

Typical applications include: emergency repairs for blast furnaces in the steel industry, lining construction for waste incinerators, building small industrial furnaces in remote areas, and applying fireproof coatings in tunnels.

4.3 Integrated Mixing and Spraying Pump

The integrated mixing and spraying pump combines mixing, conveying, and spraying functions into a single unit, eliminating the need for separate mixing equipment and delivering a “one-machine-multiple-uses” construction solution. The device mixes materials via its built-in agitator before directly conveying them through the pumping system to the nozzle for spraying, streamlining the construction process.

Key on-site construction benefits include:

– Significant space savings, particularly suited for confined industrial facilities

– Reduced coordination between equipment, easing construction organization and boosting efficiency

– Elimination of material transfer between mixing and conveying units, minimizing waste and contamination

– High integration and automated control, effectively reducing operator workload

V. Core Advantages of Using Refractory Concrete Spray Pumps

High Construction Efficiency: Achieves 2-3 times the rate of traditional manual pouring. Conventional pumps can spray 3-5 cubic meters per hour, significantly shortening furnace maintenance cycles, reducing downtime losses, and boosting corporate profitability.

Low Labor Costs: Traditional pouring requires 5-8 workers, while the spray pump needs only 1-2 operators. Its high automation reduces labor intensity and lowers personnel management expenses.

Dense and Uniform Material: Eliminates uneven compaction issues common in traditional methods. High-pressure spraying creates a dense, defect-free lining that enhances high-temperature resistance, wear resistance, and corrosion resistance, extending service life.

Strong Bonding: High-speed material projection forms mechanical interlocking with high bonding strength. Prevents lining detachment under high temperatures, ensuring furnace/kiln operational safety.

Minimal Material Waste: Significantly reduces material transportation and rebound loss compared to traditional methods, with wet spraying pumps delivering particularly notable savings on high-cost refractory materials.

Enhanced Construction Safety: Automated remote operation mitigates risks from high temperatures and falling objects. Wet spraying technology reduces dust pollution, improving both operational safety and environmental performance.

VI. Primary Industrial Applications of Refractory Concrete Spraying Pumps

6.1 Steel Industry

The steel industry represents a core application area for refractory concrete spraying pumps, primarily used for lining construction and maintenance of critical equipment like blast furnaces, ladles, and tundishes. As the central apparatus in steel production, blast furnace linings endure prolonged exposure to high-temperature molten material erosion. Spraying pump construction enables rapid lining repairs, shortening maintenance downtime. Ladles, used to hold molten steel, require linings with exceptional high-temperature resistance and wear resistance. Shotcrete construction ensures dense and well-bonded linings, extending ladle service life. Tundishes, as critical equipment for molten steel transfer, have lining quality directly impacting steel purity. Shotcrete enables precise shaping and uniform coverage of the lining.

6.2 Cement Industry

In the cement industry, shotcrete pumps are primarily used for lining construction in rotary kilns, preheaters, and similar equipment. The rotary kiln is the core equipment for calcining cement clinker. The lining in its high-temperature zone must withstand temperatures exceeding 1500°C and material erosion. Shotcrete pump construction enables rapid pouring and repair of the lining, ensuring stable kiln operation. Preheaters serve as preheating equipment in cement production, where internal linings must resist erosion from high-temperature flue gases and materials. Shotcrete application enhances lining wear resistance and sealing integrity, reduces heat loss, and improves preheating efficiency.

6.3 Power Industry

In the power sector, shotcrete pumps are primarily used for lining construction in boilers, incinerators, and similar equipment. Boilers are core components of thermal power generation. The furnace walls and convection tubes require refractory linings to withstand high-temperature flue gas erosion. Shotcrete application ensures uniform coverage, safeguarding boiler thermal efficiency and operational safety. Waste incinerators process municipal waste under high temperatures and corrosive gases. Refractory linings applied via shotcrete effectively withstand heat and corrosion, extending furnace lifespan.

6.4 Other Industries

Beyond the above sectors, refractory concrete shotcrete pumps are widely used in non-ferrous metallurgy, petrochemicals, and other fields. In non-ferrous metallurgy, they are used for lining construction in smelting furnaces for metals like copper and aluminum, resisting erosion from molten metals and slag. In petrochemicals, they are employed for lining process heaters, reactors, and other equipment, ensuring stable operation under high-temperature, high-pressure, and corrosive conditions.

VII. How to Select the Right Refractory Concrete Spray Pump? Selection Guide

First, select the pump type based on the refractory material. For wet refractory concrete, choose a wet-mix pump to ensure stable material delivery and spray quality. For dry refractory powder, opt for a dry-mix pump to enhance construction flexibility. If workspace is limited and both mixing and spraying functions are required, an integrated mixing-and-spraying pump is the optimal choice.

During selection, focus on these core factors: Output capacity (cubic meters per hour) must be determined based on project scale and construction timeline to ensure the pump’s output meets progress requirements. Maximum delivery distance and height should align with site layout—for long-distance operations in large factories or elevated work, choose pumps with greater delivery capability. Maximum aggregate size, which must match the aggregate specifications of the refractory concrete to prevent pipeline blockages caused by oversized aggregates; Power system: Electric pumps are preferable for sites with stable power supply, offering lower energy consumption and more stable operation. Diesel-powered pumps are more suitable for remote or off-grid locations.

Site conditions and construction requirements are also critical selection factors. For confined spaces, compact and mobile pump models are preferable. In dusty environments or where environmental standards are stringent, wet-mix pumps should be prioritized to minimize dust pollution. For projects with tight schedules, equipment offering higher efficiency and greater reliability is essential.

Pump reliability and maintainability are critical considerations. Industrial furnace construction—particularly maintenance projects—demands exceptionally stable equipment. Equipment failure directly impacts construction schedules and incurs significant economic losses. Therefore, select pump models with proven designs and reliable components. Additionally, prioritize equipment with straightforward maintenance procedures and readily available wear parts to minimize repair complexity and costs.

VIII. Key Technical Parameters for Selection

Pumping Capacity: The maximum hourly output (cubic meters per hour) is the core parameter for ensuring construction progress. Selection should align with the project’s daily output volume and total duration, choosing equipment with matching capacity to avoid delays from insufficient output or idle equipment and energy waste from excessive capacity.

Maximum Pressure: Directly determines the equipment’s delivery capability, including distance and height. Higher maximum pressure enables longer horizontal and greater vertical delivery distances. When selecting equipment, choose a pump model with sufficient pressure based on the actual delivery distance (horizontal and vertical) at the construction site to ensure materials can be delivered smoothly to the construction area.

Conveyance Distance (Horizontal and Vertical): Maximum conveyance distances vary by pump type—e.g., dry-mix pumps typically achieve greater horizontal distances than wet-mix pumps. Accurately measure the site’s conveyance distance and height to ensure the equipment’s capacity meets operational requirements.

Mixing Efficiency: Primarily relevant for equipment with mixing capabilities. Higher mixing efficiency ensures more uniform material blending and more stable lining performance. When selecting equipment, focus on parameters such as mixing power and mixing speed, prioritizing units with superior mixing performance.

Wear-Resistant Components: Due to the high abrasiveness of refractory materials, the quality of wear-resistant components directly impacts equipment lifespan. Pay attention to the materials used for these components, such as high-chromium alloys or wear-resistant ceramics, while also understanding the replacement cycles and procurement costs of wear parts.

Control Systems and Automation Level: Higher automation simplifies operation, stabilizes construction quality, and reduces operator skill requirements. Select equipment with manual, semi-automatic, or fully automatic control systems based on project needs. Fully automatic systems typically feature touchscreen operation, parameter monitoring, and fault alerts, making them ideal for large-scale, high-standard projects.

IX. Common Issues and Practical Solutions for Refractory Concrete Spray Pumps

Conveying pipeline blockages are among the most common issues, primarily caused by improper material ratios (excessive viscosity), oversized aggregate particle size, excessive pipeline bends, or overly long conveying distances. Solutions: First, stop feeding material and activate the reverse pumping function to extract material from the pipeline. If reverse pumping fails, disassemble the blocked pipeline section and flush it clear with high-pressure water. Preventive Measures: Strictly control material mix ratios and aggregate particle size. Rationally layout delivery pipelines to minimize bends and avoid excessively long transport distances.

Excessive material rebound during spraying primarily results from insufficient spray pressure, improper nozzle-to-surface distance (too far or too close), or inappropriate material viscosity. Solutions: Adjust air compressor pressure to ensure stable spray pressure. Optimize nozzle-to-surface distance, typically maintained between 0.8-1.5 meters. Adjust material viscosity—add water if wet-sprayed material is too dry, or modify the mix ratio if too thin.

Uneven spray thickness is primarily caused by unstable pump output, inconsistent spray speed, or inconsistent nozzle movement speed by operators. Solutions: Calibrate pump output to ensure stable delivery; inspect the pressure system to eliminate pressure fluctuations; enhance operator training to standardize movements and maintain uniform nozzle speed.

Excessive pump wear is primarily caused by overly abrasive refractory materials or substandard wear-resistant components not replaced promptly. Solutions: Replace wear parts with superior materials like high-chromium alloys or ceramic-coated components; shorten inspection and replacement cycles for vulnerable parts; adjust aggregate particle size within material limits to reduce abrasiveness.

Excessive pressure loss is primarily caused by pipeline blockages, loose pipe joint seals, or hydraulic system leaks. Solutions: Inspect and clear blocked pipeline sections; replace seals and tighten pipe joints to ensure proper sealing; examine hydraulic system components like pipes and valves to eliminate leaks, and replenish hydraulic fluid.