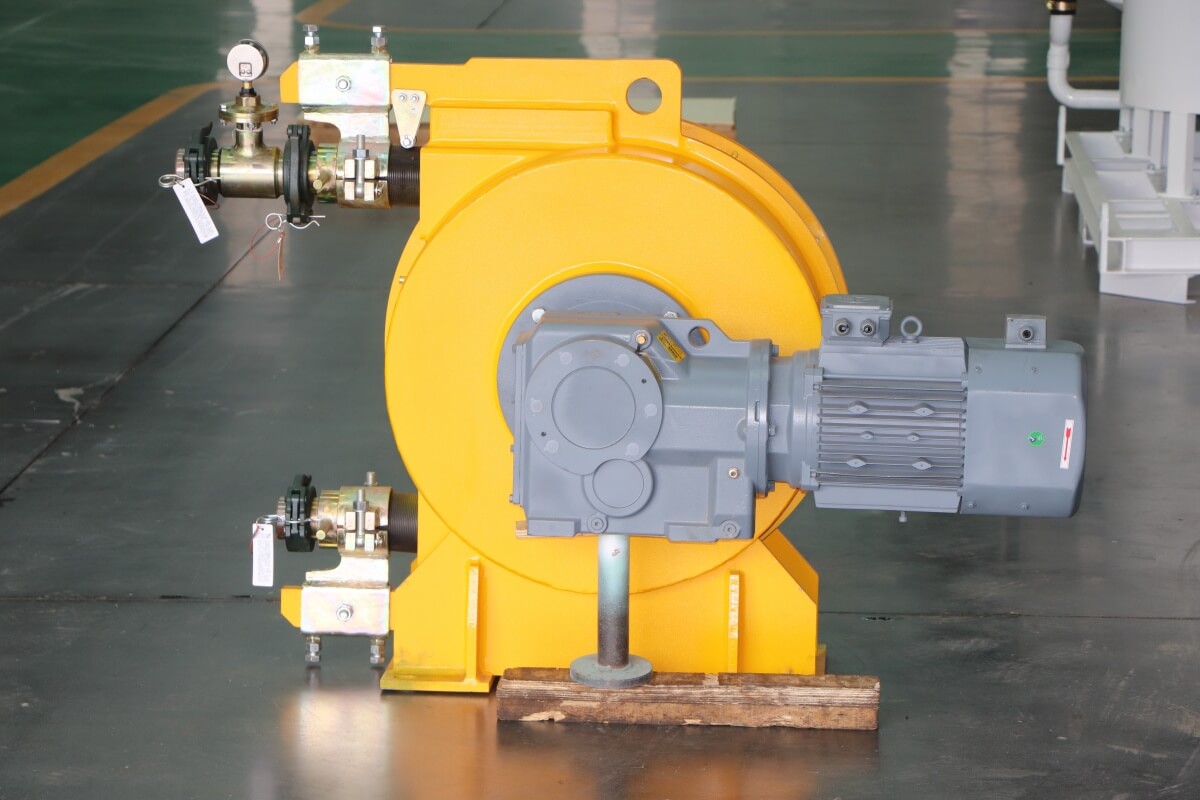

Squeeze Hose Quality Peristaltic Pump

The Squeeze Hose Quality Peristaltic Pump belongs to the rotor type volumetric pump. It is by the elasticity of the flexible element (hose) in the pump and the rotor on the roller or slide shoe work.

The material to be conveyed is surrounded by the hose and does not come into contact with other parts. The pump inlet volume, inlet and outlet volumes are limited by the inner surface of the flexible tube and are defined by the position of the pressure point on the tube between the roller or slide shoe and the wall of the pump body.

The rotor shaft is filled with grease when the bearings are installed and generally requires no special maintenance. The pump casing is filled with half volume of special glycerin as lubricant for the slide shoe and hose. The pump should be installed with adjusting shims for precise adjustment of the slide shoe to ensure pump performance and extend hose life.

Hose is generally specially made with braided nylon reinforced with high elasticity thick-walled rubber hose, which can be divided into two kinds of natural rubber hose and nitrile rubber hose according to the different conveying medium. According to the use of a certain speed, outlet pressure and temperature of the medium, the working life of the hose is 1000 ~ 8000h. The use of temperature is generally lower than 80 ℃.