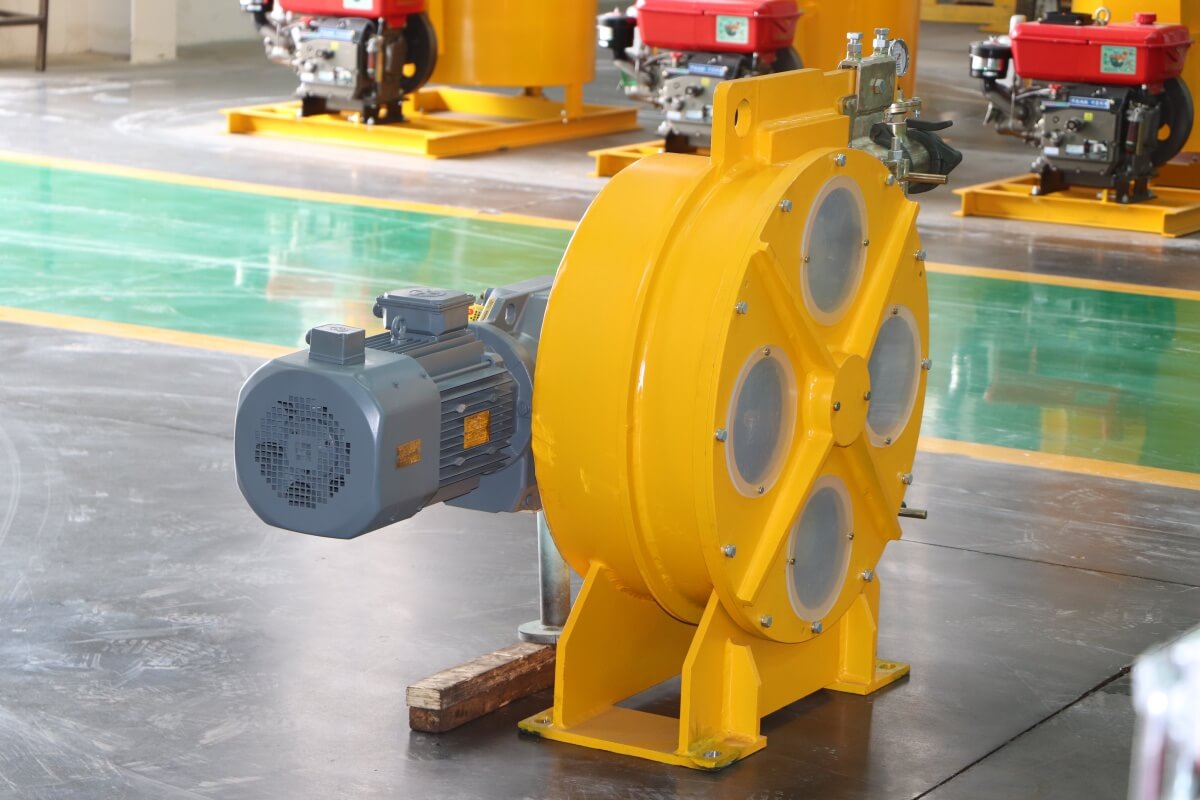

China Peristaltic Hose Pump Used for TBM

The peristaltic hose pumps produced by Leadcrete play a key role in TBM (tunnel boring machine) construction. They have the characteristics of no leakage, strong self-priming and wear resistance, which perfectly adapt to the advantages of TBM in bentonite slurry transportation and chemical grouting reinforcement.

China Peristaltic Hose Pump can transport bentonite slurry in TBM work, achieving an average daily excavation of 15 meters in complex formations, which is 3 times more efficient than the traditional drilling and blasting method, and the amount of slurry leakage is reduced by 90%.

Peristaltic Hose Pump is designed for extreme TBM conditions. Its technical advantages are:

Leak-free sealing structure

TBM construction requires the transportation of high-viscosity media such as bentonite slurry and cement grouting liquid. Traditional pumps are prone to leakage due to seal failure, polluting the environment and affecting excavation efficiency. Peristaltic hose pumps achieve transportation through squeezing hoses, without mechanical seals or valves, completely eliminating the risk of leakage. For example, in the construction of the Shantou Bay submarine tunnel of the Shantou-Shantou High-speed Railway, the pump successfully resisted the penetration of 0.985 MPa high-pressure seawater to ensure the sealing of the shield segment joints.

Strong self-priming and dry running capabilities

During TBM excavation, the pump needs to be started and stopped frequently to adapt to changes in the formation. The self-priming height of the peristaltic pump can reach 9.5 meters, and dry running will not damage the pump body, avoiding mechanical failures caused by idling of traditional pumps. In the construction of tunnels in the frozen soil area of the Qinghai-Tibet Railway, the pump can stably transport low-temperature mud and adapt to extreme temperature difference environments.

Wear-resistant and long-life design

In tunnel construction, the medium often contains hard particles such as sand, gravel, and rock debris, which cause serious wear on the pump body. The peristaltic pump hose material can be selected from NBR (nitrile rubber), CSM (chlorosulfonated polyethylene), etc., and its wear resistance far exceeds that of traditional metal pumps. For example, a TBM project uses the IHP90Z pump manufactured by Hefei Huayun Machinery, and the hose life is more than 800 hours, which is 3 times higher than that of traditional pumps.