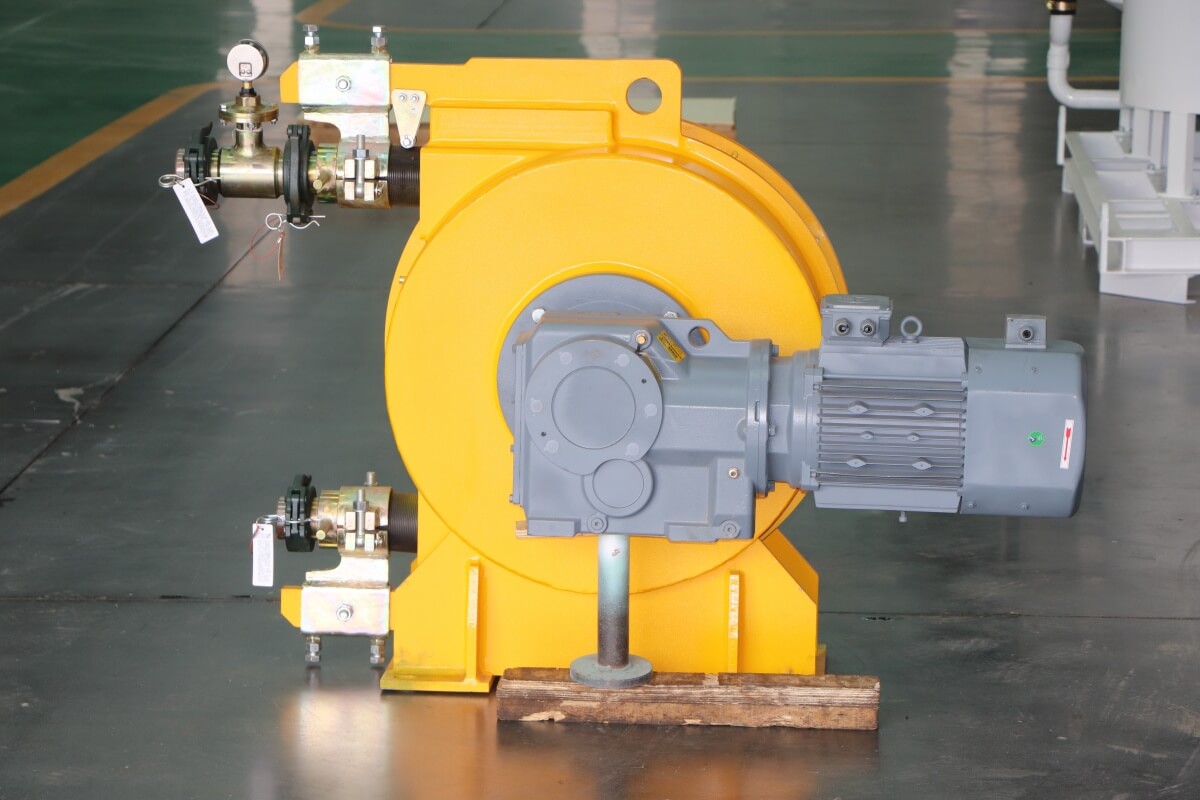

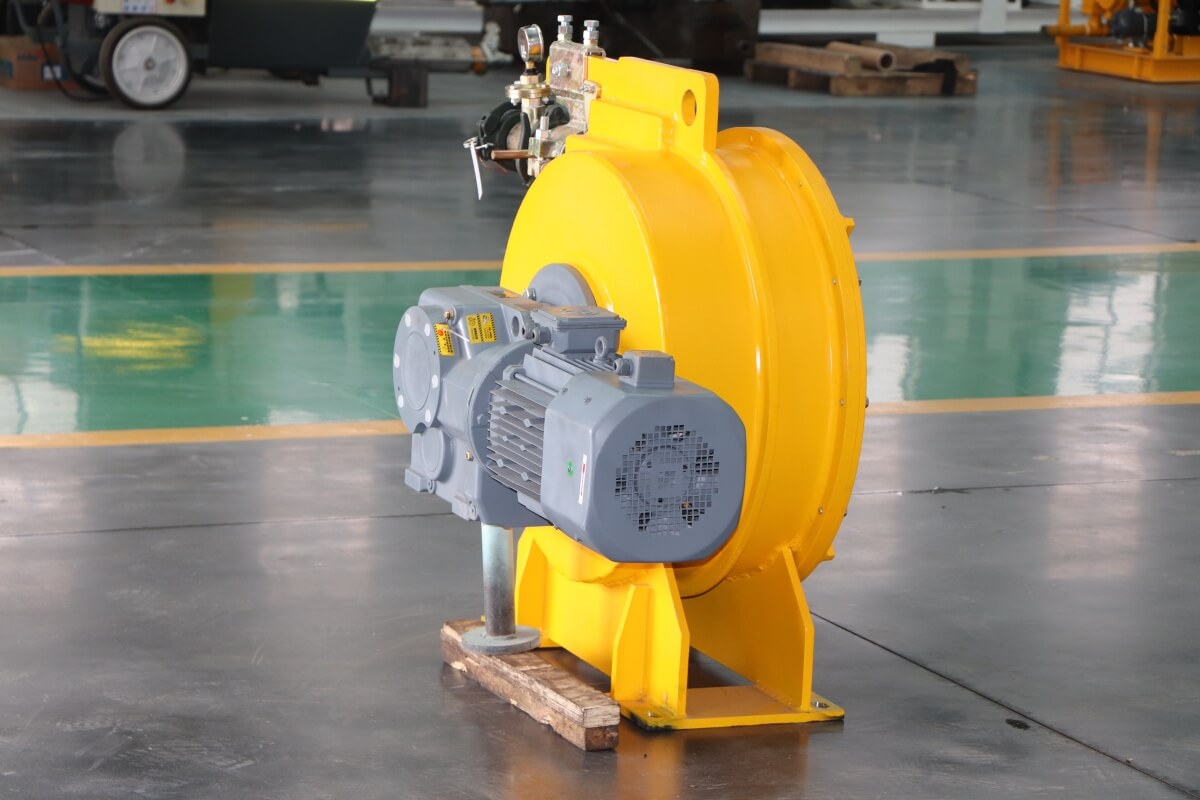

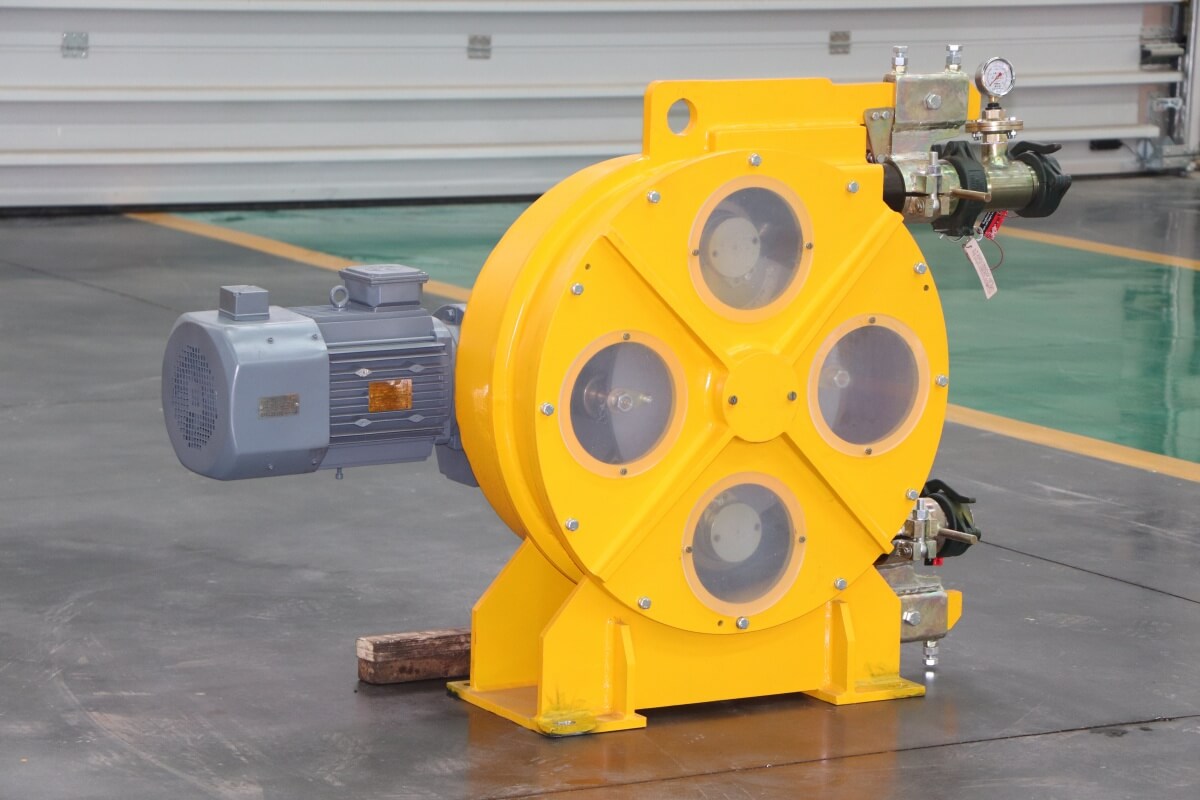

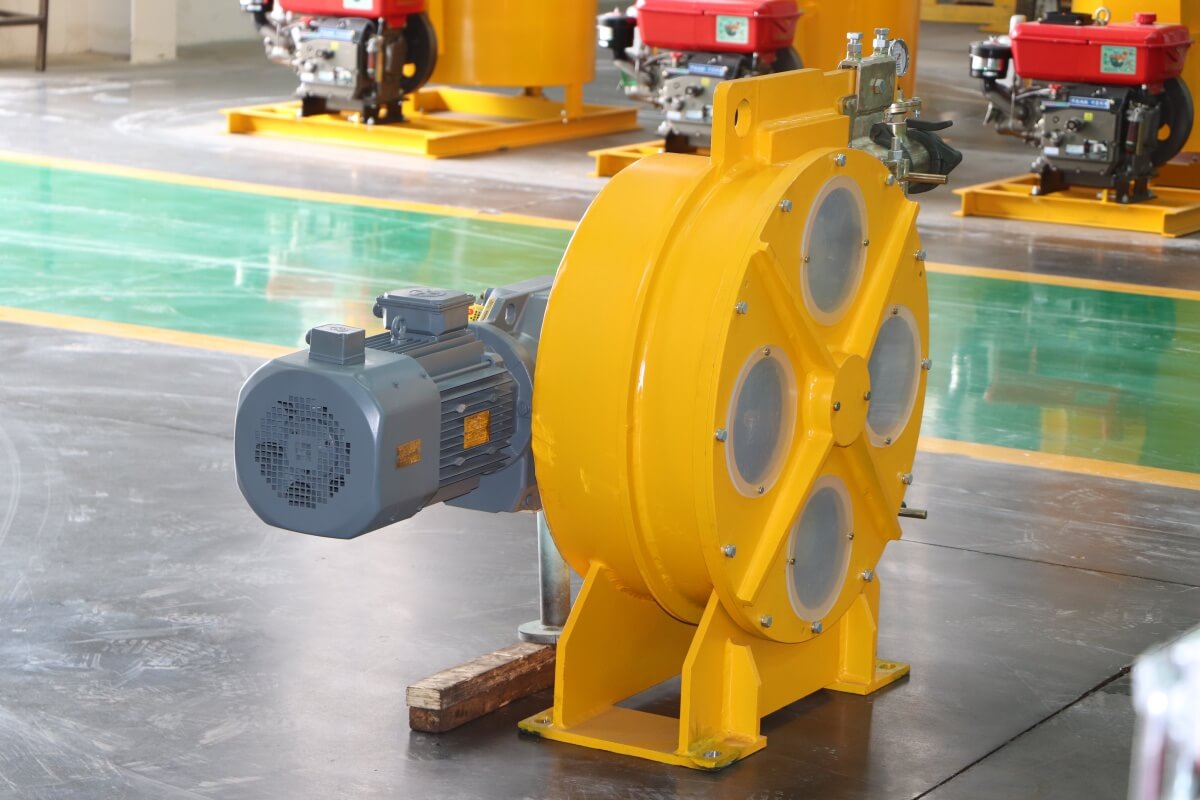

Hose pump for pumping contains solid particles

Hose pump for pumping contains solid particles typical applications:

Industrial: Mining slurries, ceramic slip, concrete pumping.

Water/Wastewater: Sewage, activated sludge, lime dosing.

Food & Beverage: Fruit pulps, yeast slurries, dough.

Chemical: Paints, inks, resins with fillers.

Hose pumps are cost-effective for abrasive/solid-laden applications due to their simplicity and long hose life.

Why hose pumps excel with solid-laden fluids:

Gentle Handling, No Valves/Seals

Fluid only contacts the hose/tube (the only wearing part), not the pump mechanism.

No valves, glands, or seals to clog or wear from abrasive particles.

Ideal for slurries, wastewater, food slurries, ceramics, and mining slurries.

No Clogging

Particles pass freely through the large-diameter hose lumen.

Suitable for solids up to 80% of the hose ID (e.g., 20 mm solids in a 25 mm hose).

Low Maintenance

Only the hose needs replacement (no complex internal parts).

Minimal downtime compared to pumps with worn impellers/seals.

Self-Priming & Dry Run Capability

Can run dry without damage and self-prime up to 9.5 m (31 ft).

Precise Flow Control

Flow rate is directly proportional to speed (linear accuracy).

No slippage, even with high-viscosity fluids.

Features of hose pump for pumping contains solid particles:

Hose Material:

Natural rubber (abrasive slurries), EPDM (chemicals), or Buna-N (oils).

Reinforced with fabric layers for pressure resistance.

Roller/Shoe Design:

Rollers gently compress the hose (minimizes wear).

Shoe designs offer higher pressure but faster hose wear.

Pressure Rating: Typically up to 16 bar (232 psi) (varies by model).