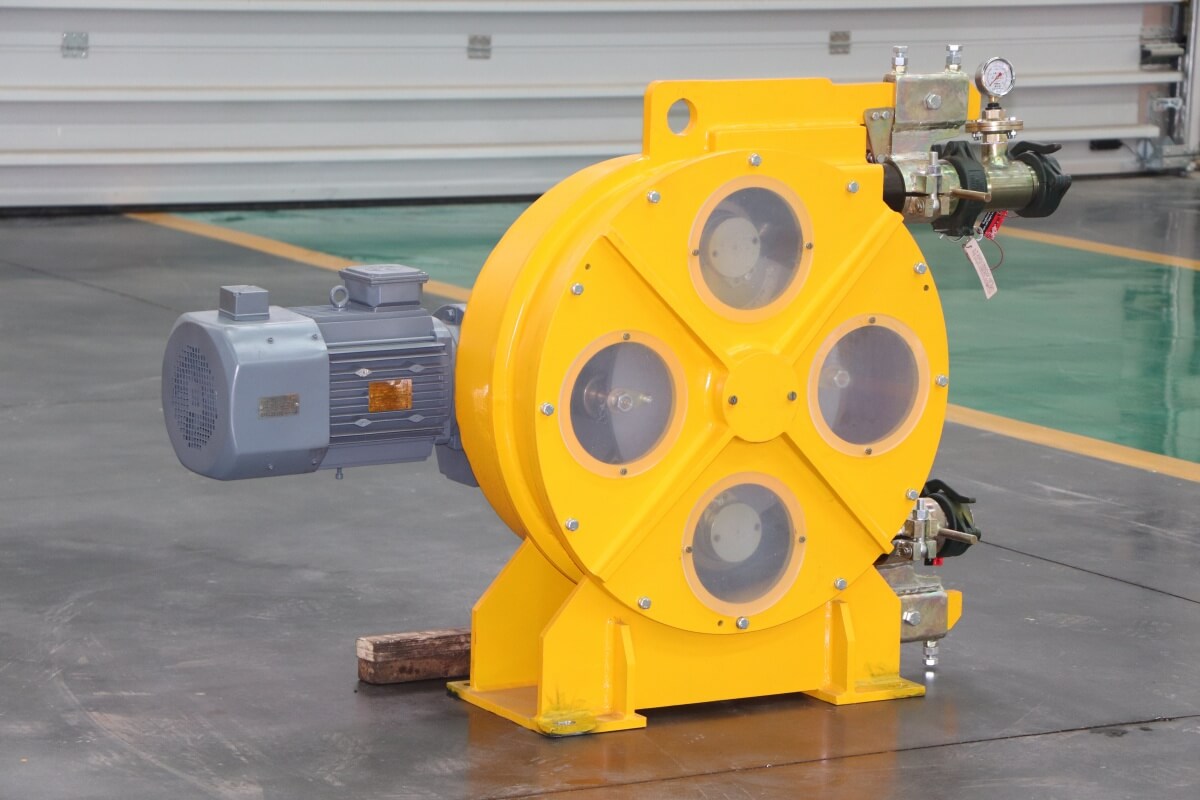

Heavy-Duty Industries Hose Pump

The heavy-duty industrial hose pump is mainly composed of a pump body, a rotor, a roller, an idler, an extruded hose and a drive unit. Its working principle is to drive the roller to rotate through the rotor, so that the hose is squeezed and deformed. After the roller rotates, the deformed hose relies on its elasticity to restore its original shape, thereby generating negative pressure to suck in the fluid, and discharge it through the outlet under the push of the roller, and finally forming the pressure delivery of the fluid.

Heavy-Duty Industries Hose Pump Main Features:

No seal and no valve: The design of the hose pump avoids the sealing and valve problems of traditional pump equipment, reducing leakage and maintenance costs.

Self-priming ability: The hose pump has self-priming ability and can easily extract liquids.

Dry running without damage: The hose pump will not be damaged even if it runs without liquid.

Reversibility: The hose pump can run in reverse, which is convenient for cleaning and troubleshooting.

Contactless delivery: There is no direct contact between the fluid and mechanical parts, avoiding contamination and wear.

Can transport fluids containing solid particles: Hose pumps can transport fluids containing solid particles and are suitable for a variety of complex working conditions.

Heavy-Duty Industries Hose Pump Application areas:

Heavy-duty industrial hose pumps are favored by users due to their unique performance and wide range of applications. The following are some typical application areas:

Construction and underground engineering: used to transport building materials such as concrete and mortar.

Petrochemical: used to transport various chemicals and petroleum products.

Metallurgy: used to transport fluids in metal smelting processes.

Food industry: used to transport food raw materials and finished products such as dairy products, juice, etc.

Ceramics and glass: used to transport ceramic slurry and glass melt.

Mining: used to transport slurry and tailings, etc.

Water treatment: used for the treatment and transportation of sewage and wastewater.

Pharmaceuticals: used to transport liquid medicines and preparations, etc.