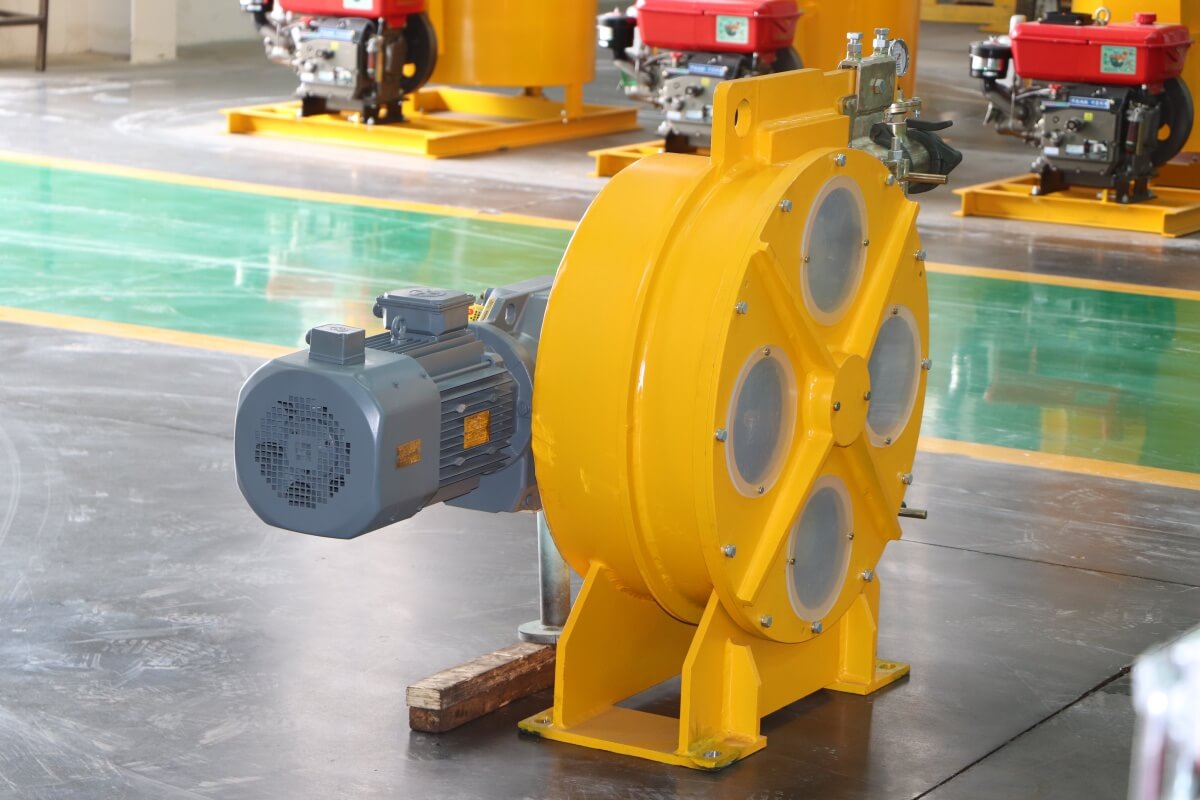

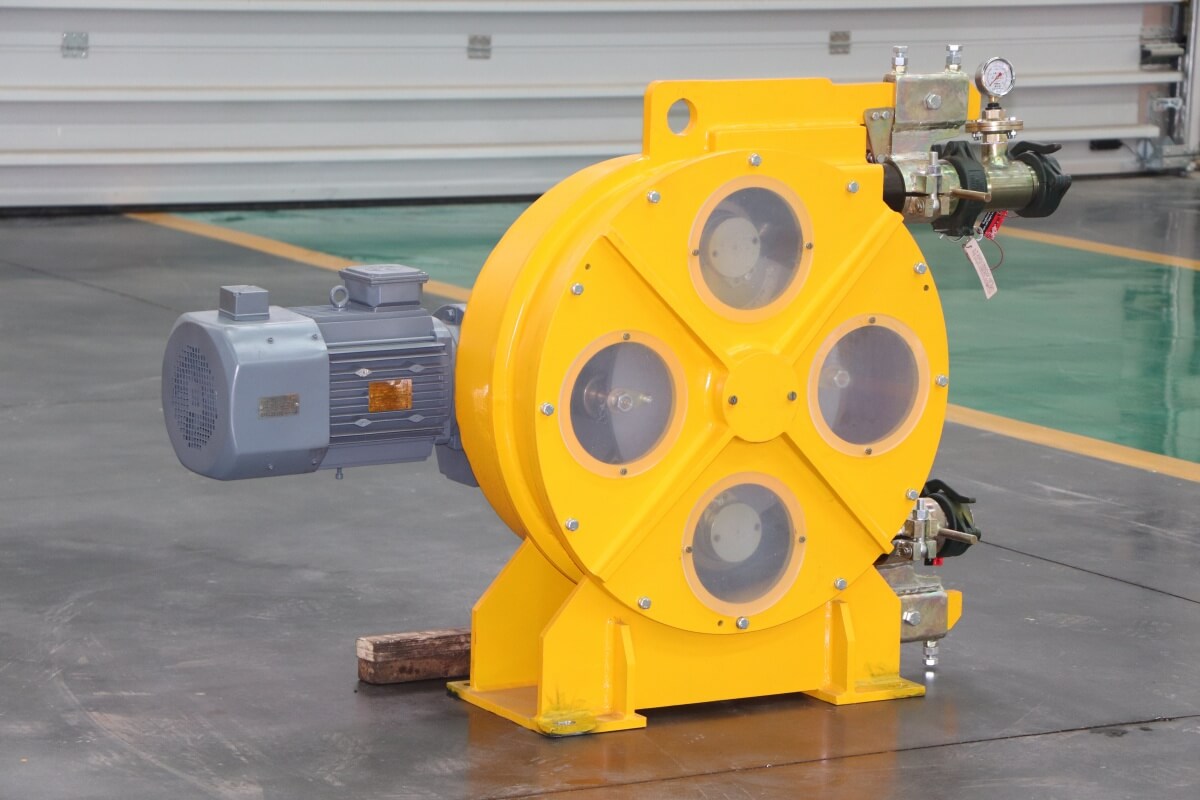

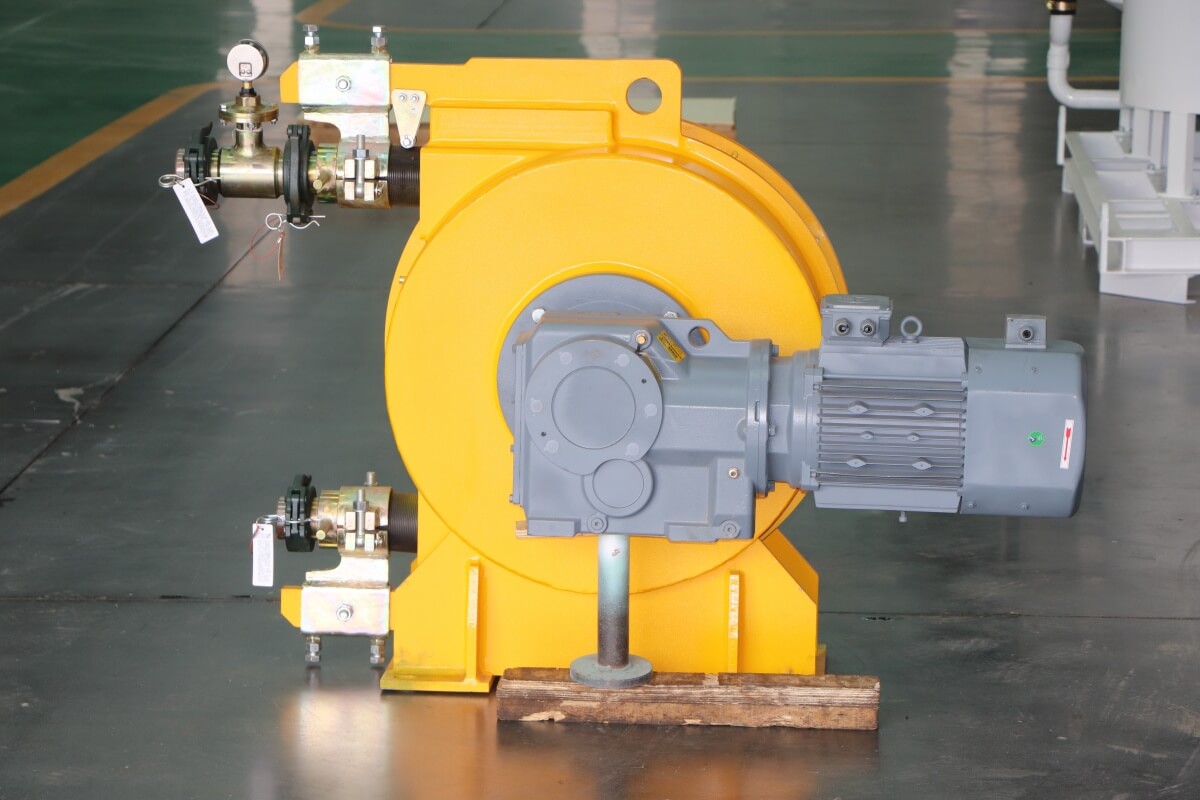

Hose pump for pumping solutions with low and high viscosity

Hose pump for pumping solutions with low and high viscosity applications:

Low Viscosity: Water treatment, chemical dosing, beverages.

High Viscosity: Food processing (dough, mayonnaise), adhesives, ceramic slip, wastewater sludge.

Leadcrete Equipment can supply you with high quality hose pump for pumping solutions with low and high viscosity from China, hose pumps (peristaltic pumps) are highly versatile for pumping solutions across a wide viscosity range, from low-viscosity fluids (e.g., water, solvents) to high-viscosity materials (e.g., pastes, gels, sludges). Their design inherently adapts to viscosity changes, with key advantages and considerations outlined below:

Handling Low-Viscosity Fluids

Ease of Pumping:

Low-viscosity fluids (e.g., water, dilute chemicals) flow easily through the hose. The pump’s peristaltic action (rollers compressing the hose) creates suction and discharge without resistance.

Advantages:

No Cavitation: Unlike centrifugal pumps, hose pumps do not cavitate at low viscosities.

Precision: Flow rates remain linear and predictable, even at high speeds.

Self-Priming: Effective for drawing low-viscosity fluids from containers or sumps.

Considerations:

Flow Rate: Low viscosity may require higher pump speeds to achieve desired flow rates.

Hose Selection: Thinner-walled hoses (e.g., natural rubber) work well for non-abrasive, low-viscosity fluids.

Handling High-Viscosity Fluids

Adaptability:

Hose pumps excel with high-viscosity fluids (e.g., adhesives, food dough, mining slurries) due to their positive displacement design. The hose fully recovers after compression, maintaining consistent volume per revolution.

Advantages:

No Slippage: Unlike centrifugal pumps, flow rate remains stable regardless of viscosity.

Gentle Handling: Low shear minimizes degradation of shear-sensitive materials (e.g., polymers, emulsions).

Solid Tolerance: Can pump fluids with suspended solids (e.g., pastes with particulates) without clogging.

Considerations:

Torque Requirements: High-viscosity fluids demand more torque from the motor. Ensure the pump is sized for the viscosity (check manufacturer specs).

Hose Stiffness: Thick-walled or reinforced hoses (e.g., EPDM, silicone) resist collapse under high pressure.

Temperature: Viscosity increases with cooling; pre-warm thick fluids if necessary.

Speed Adjustment: Lower speeds may be needed to prevent hose fatigue in extremely viscous applications.