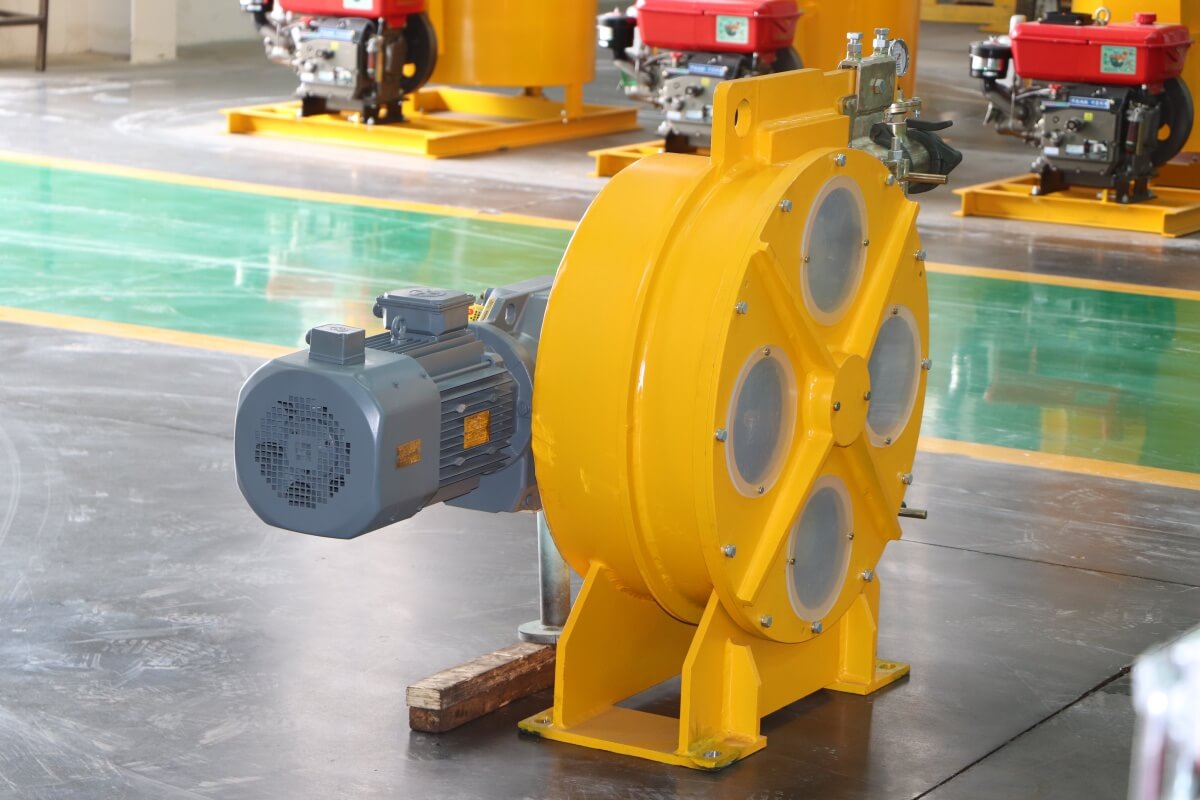

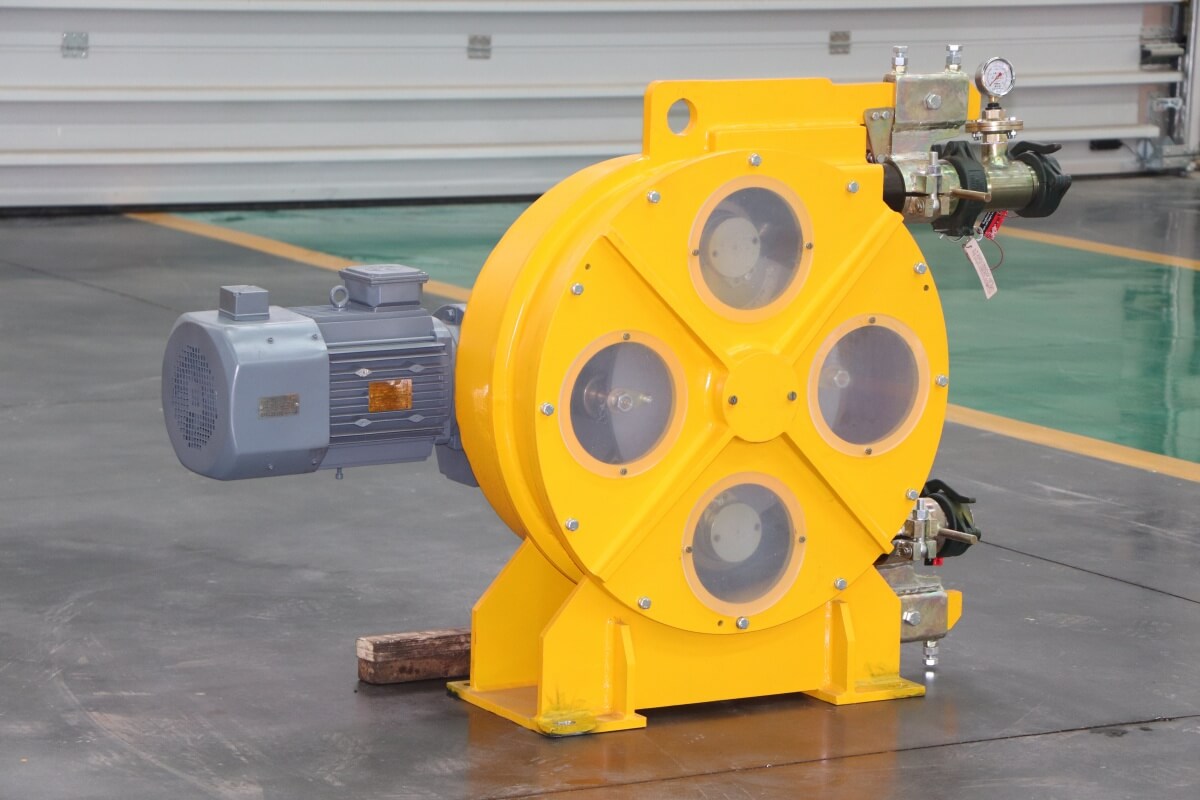

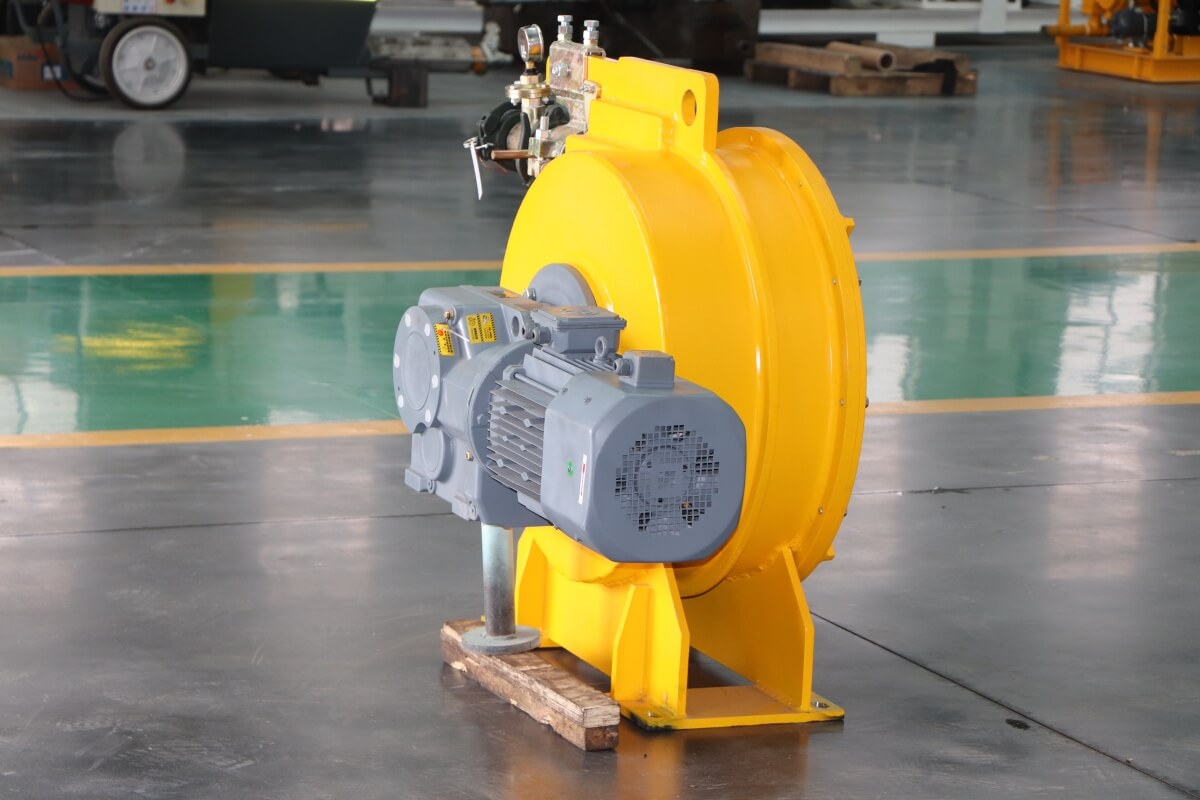

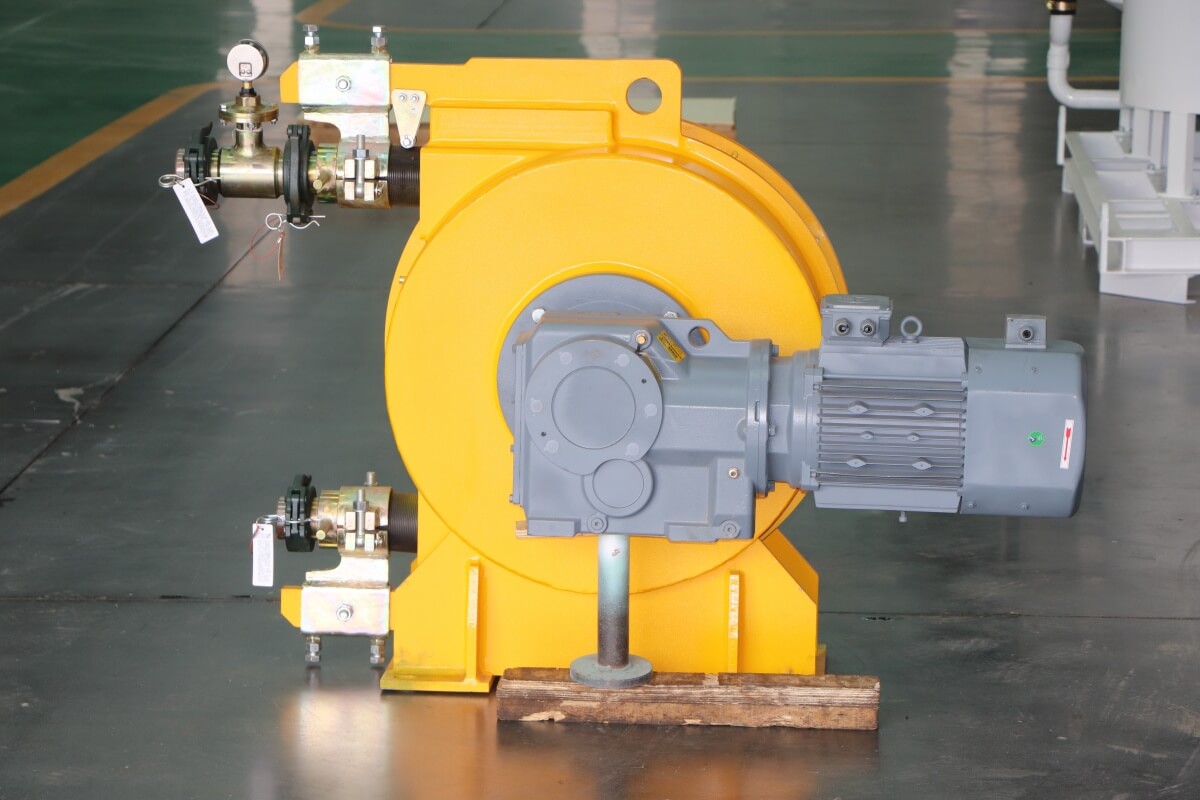

Peristaltic squeeze pump for concrete

A peristaltic squeeze pump is a specialized tool for pumping concrete where traditional pump valves would fail quickly due to clogging or wear. Its valveless design excels with aggressive, fiber-reinforced, or coarse mixes, particularly in medium-volume applications, confined spaces, or repair/grouting work.

Peristaltic squeeze pump for concrete ideal applications:

Specialty Placement: Pumping into confined spaces, narrow forms, or complex geometries.

Grouting & Anchoring: Cementitious grouts, micro-piles, soil stabilization.

Repair & Refurbishment: Mortars, shotcrete (with acceleration nozzle), resurfacing.

Precast & Architectural Concrete: Countertops, panels, small precast elements.

Fiber-Reinforced Concrete: Handles fibers better than piston pumps.

Low-Volume Jobs: Where high-cost piston pump setup isn’t justified.

Abrasive/Corrosive Mixes: Where component wear is a critical concern.

Key limitations & considerations of peristaltic squeeze pump for concrete:

Hose Wear & Cost:

The flexible hose is the main consumable. Wear life varies (hours to hundreds of hours) depending on concrete abrasiveness, pressure, and hose quality.

High-quality hoses are expensive, significantly impacting operating costs.

Flow Rate & Pressure:

Typically lower maximum flow rates (often 15-20 m³/h or 40-55 US gpm, though larger industrial models exist) compared to large piston pumps.

Typically lower maximum discharge pressures (often up to 15-20 bar, though some achieve higher) compared to high-pressure piston pumps.

Pulsating Flow: The peristaltic action creates a pulsating output, which may require damping for certain applications.

Aggregate Size Limit: Maximum aggregate size is limited by hose diameter (typically ≤ 1/3 of hose ID).

Power Consumption: Can be relatively high due to friction from hose compression.

Hose Fatigue: Repeated flexing causes eventual fatigue failure, even if the hose appears intact externally.