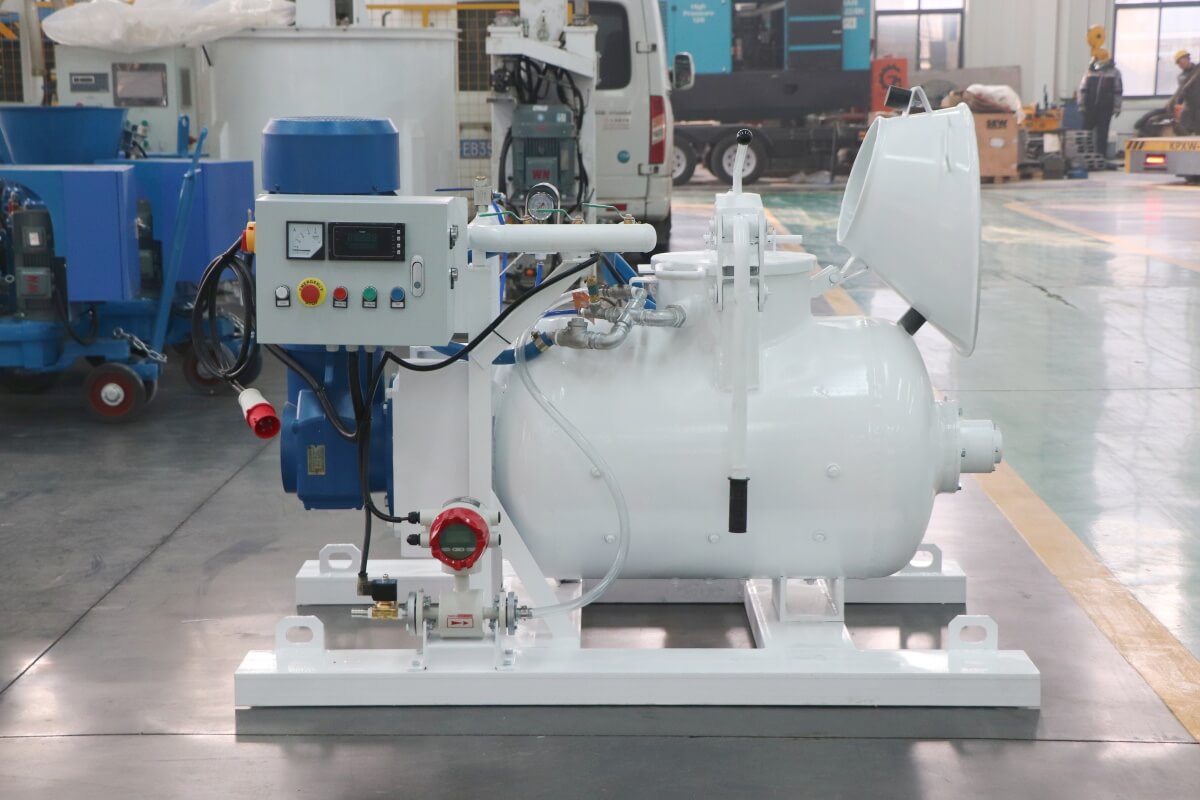

Refractory gunning machine for forming the refractory linings

A refractory gunning machine is a specialized piece of equipment used in industrial applications to apply refractory materials, forming protective linings on the surfaces of high-temperature equipment such as furnaces, kilns, and reactors. These linings are crucial for maintaining structural integrity, reducing heat loss, and protecting equipment from chemical and thermal degradation.

The refractory gunning machine serves as a specialized equipment employed for the purpose of spraying refractory materials, which is essential in forming durable and protective refractory linings within critical industrial environments such as furnaces, kilns, and reactors. This machine plays a pivotal role in ensuring the structural integrity and operational efficiency of these high-temperature vessels by providing a uniform and robust lining that can withstand extreme thermal and chemical stresses.

Key components and features of a refractory gunning machine for forming the refractory linings:

Material Delivery System:

Hopper: Holds the dry refractory mix (usually a blend of aggregates, binders, and additives).

Conveying Mechanism: Transports the material from the hopper to the gunning nozzle. This can be pneumatic (using compressed air) or mechanical (using screws or augers).

Gunning Nozzle:

Designed to project the refractory material at high velocity onto the surface being lined.

Adjustable for different spray patterns and angles to suit various application needs.

Water Addition System:

Introduces a controlled amount of water to the dry mix just before or during gunning to achieve the desired consistency for proper adhesion and setting.

Control System:

Automated or manual controls to regulate material flow, water addition, and gunning pressure.

Ensures consistent application and quality of the refractory lining.

Power Unit:

Provides the necessary energy to operate the conveying mechanism, water addition system, and other components.

Can be electric, diesel, or pneumatic, depending on the application and mobility requirements.

Applications of refractory gunning machines:

Steel Industry: Linings for ladles, tundishes, and reheating furnaces.

Cement Industry: Protective linings for kilns and preheaters.

Power Generation: Linings for boilers and incinerators.

Petrochemical Industry: Linings for reactors and heat exchangers.