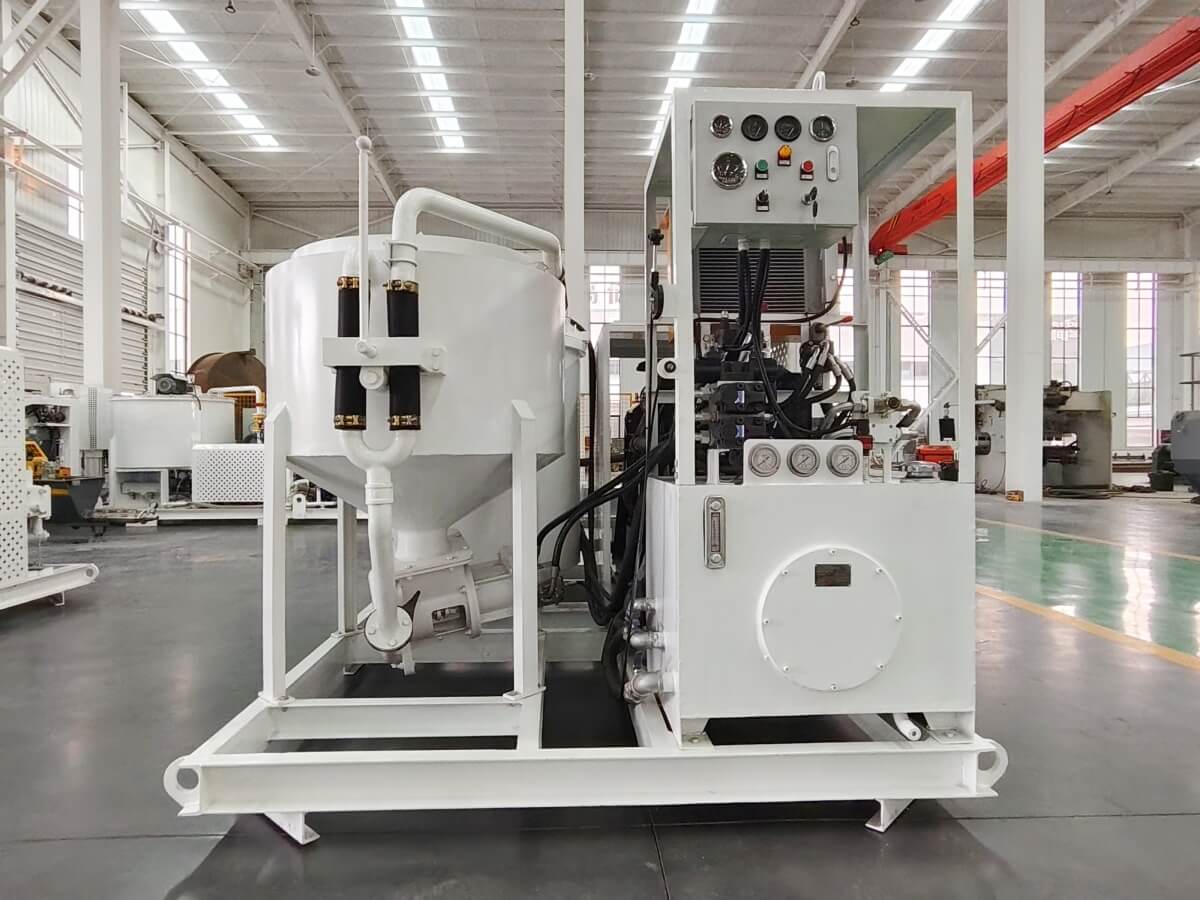

Today we shipped a diesel grouting mixer pump Saudi Arabia to our Saudi Arabia customer. The customer is working on a tunnel engineering project. He told us that he wanted such a compact diesel-powered diesel grouting plant unit with a grouting mixer, agitator and piston grout pump as the core facility of grouting construction. The pre-mixed grout is evenly injected into the rock layer or soil through a high-pressure pumping system to achieve multiple effects such as reinforcement, water stopping and filling.

Through multiple rounds of technical negotiations, the business manager systematically sorted out the customer's core requirements for the grouting pump station:

1. Performance parameters: The grouting station output flow must cover the range of 8-200L/min, and the maximum working pressure must reach 16MPa to adapt to the grouting strength under different geological conditions;

2. Slurry adaptability: It must support an adjustable range of water-cement ratio from 0.5:1 to 1:1, and be compatible with cement-based, chemical slurry and other multi-media transportation;

3. Construction coordination: In view of the characteristics of tunnel narrow space operations, it is proposed that the grout equipment must have modular design, rapid disassembly and assembly, and remote monitoring functions, and it is required to be equipped with emergency pressure relief devices to ensure safe operation.

Based on the above requirements, the technical team finally determined the customized solution of the diesel-powered high-pressure grouting plant through CFD flow field simulation and structural strength verification. After the customer's technical review and order confirmation, our company completed the assembly and commissioning of the grouting mixer pump equipment according to the contract requirements. After 72 hours of continuous load testing, key indicators such as equipment flow stability (±2%) and pressure fluctuation value (≤0.5MPa) are better than the requirements of the technical agreement. Today, we will coordinate logistics to complete moisture-proof packaging, fixed lashing and GPS positioning equipment installation, start special vehicle transportation, and transport it to the port for delivery to customers.

Your position:

Home > News > Product News

Diesel grouting mixer pump Saudi Arabia

date: 2025-07-03

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)