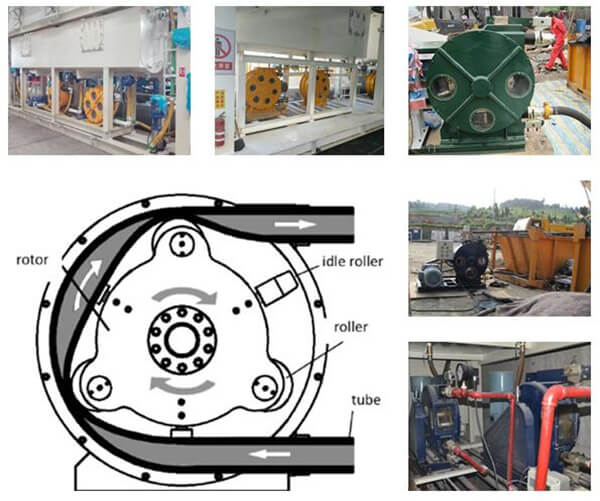

Using a hose pump to transport the pulp to the filter press, the thickener discharge can directly transport the pulp to the filter press, eliminating all links.

1. The concentration of the slurry conveyed by the hose pump can reach 80%, and the concentration can be reduced without adding stirring and irrigation.

2. The accuracy of quantitatively conveying the slurry is not more than ±5%, which greatly improves the working efficiency of the filter press.

3. There is absolutely no leakage. All media flows inside the hose. VERDER's hoses usually have a lifespan of more than 2,000 hours (the actual lifespan depends on the use of the site. Operation data in the Zambia gold mine in South Africa: the shortest continuous operation life is 4.5 months, and the longest lifespan is 11 months and 7 days) . VERDER's hoses are made of NR, NBR, NBRF, EPDM, CSM and other materials to meet the transportation needs of various highly corrosive and highly abrasive media.

4. Non-clogging pumping. The hose pump can not only run dry, but also reverse. If the pump inlet is blocked, the electrode power will increase to a certain extent. The thermal protection device releases the contactor and reverses the electrode to knock out the blockage at the inlet. When restarting, it is feeding in the forward direction again, and there is no blockage at all.

5. Easy to maintain. The only wearing part of a hose pump is the hose. VERDER's hose pump is very convenient to replace the hose, the hose diameter is less than 65 in less than 30 minutes, and the replacement of the large pump tube with a diameter of 125 does not exceed 120 minutes.

6. Greatly reduce operating costs. The total power is generally above 60 kilowatts. The same system hose pump delivers fully as long as 22 kW. (It can save 38 kWh of electricity per hour. Calculated by working 20 hours a day, 360 days a year, 0.5 yuan per kWh of electricity, it can save 136,800 yuan per year. Maintenance work: Figure 2 The maintenance of the mixer and submerged pump requires 5,000 yuan per hoisting. , The pump accessories are more than 20,000 yuan, and the annual maintenance cost is more than 50,000 yuan. The hose pump consumes 3 hoses a year, and the market price of 3 hoses is 30,000 yuan.

If you want to buy a hose pump to transport the pulp directly to the filter press, you can contact me directly, email: sales1@leadcrete.com

Your position:

Home > News > Product News

Hose pump to transport the pulp to the filter press

date: 2022-04-09

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)