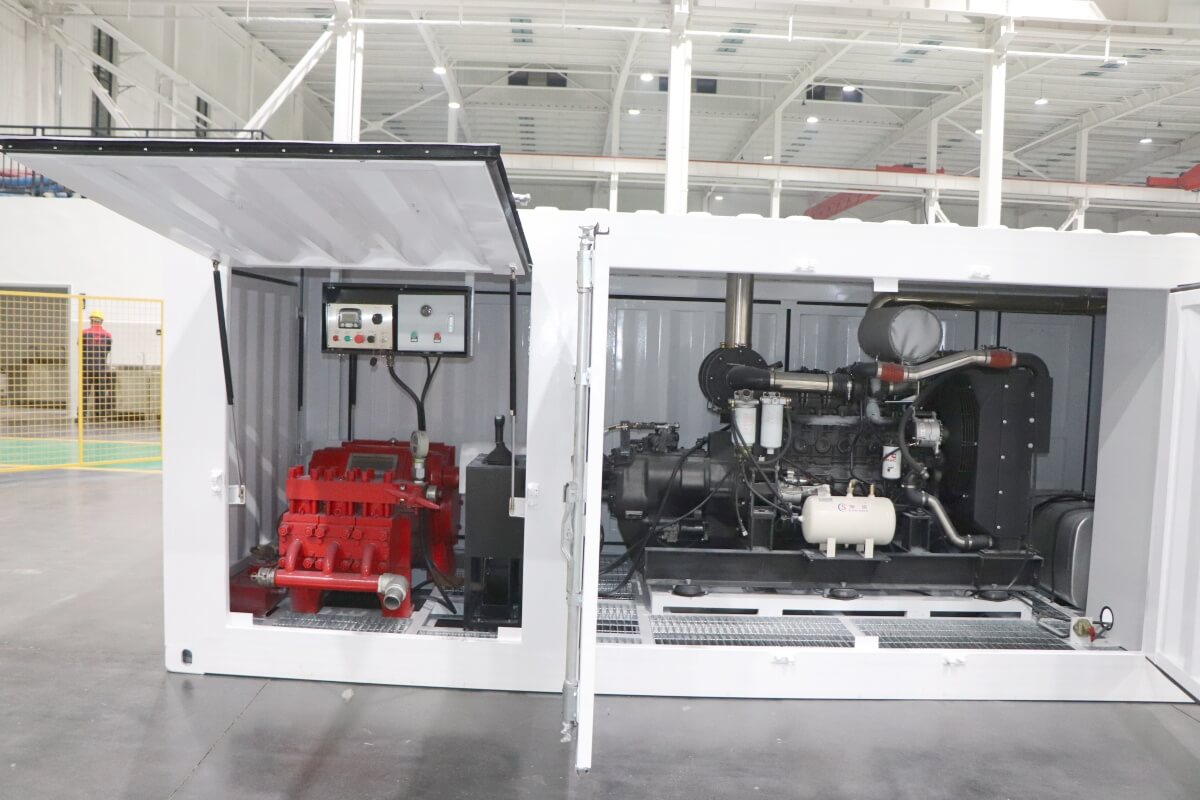

Container Type Grout Injection Pump

A Container Type Grout Injection Pump is a specialized piece of equipment designed for injecting grout into the ground or rock formations, with the pump and its associated components housed within a containerized structure. They are mainly used for engineering applications such as enhancing structural stability, preventing leakage, and improving foundation conditions.

Container Type Grout Injection Pump, also known as container type grout injection pump, is a kind of equipment specially designed for grouting operations in construction and civil engineering projects.

Features of container type grout injection pumps:

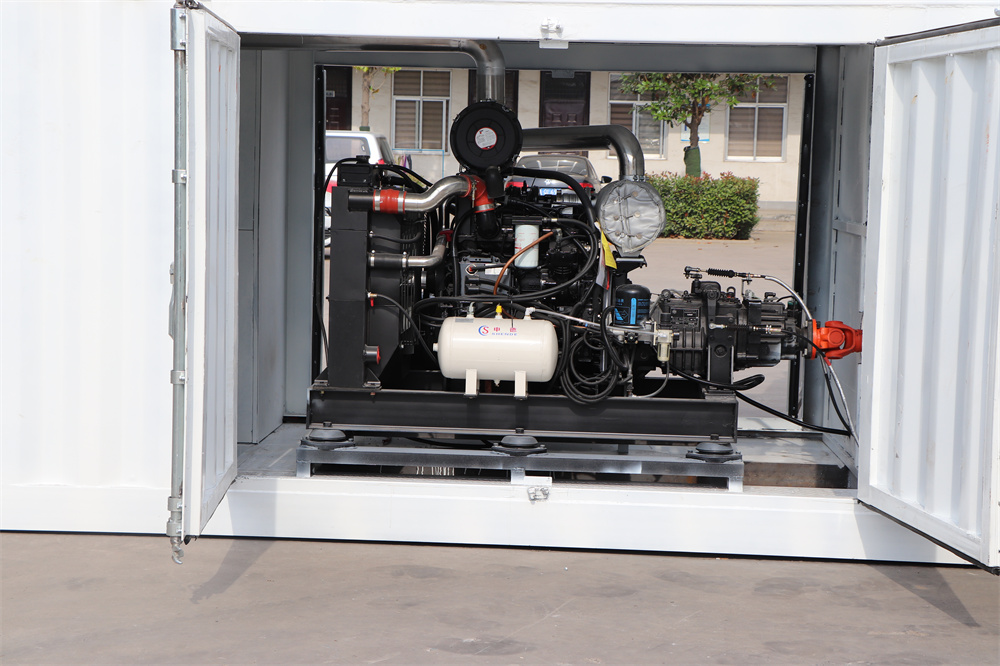

Containerized Design:

Portability: The pump is housed in a container, which allows for easy transportation to remote construction sites.

Modularity: The container can be customized to include additional storage for grouting materials, power generators, or control systems, making it a versatile solution for various project needs.

Protection: The container provides protection for the pump and other equipment from the elements, reducing wear and tear.

High-Pressure Grouting Capability:

These pumps are capable of generating high pressure to inject grout into the ground, which is essential for stabilizing soil, filling voids, and preventing water ingress.

They can handle a variety of grouting materials, including cement-based grouts, chemical grouts, and polyurethane resins.

Efficiency and Precision:

Container Type Grout Injection Pumps are designed for efficient operation, with precise control over the flow rate and pressure of the grout being injected.

This precision is crucial for ensuring that the grouting process is effective and that the desired results are achieved.

Durability and Reliability:

These pumps are built to withstand the harsh conditions of construction sites, with robust construction and high-quality components.

They are designed for long-term use, with minimal maintenance requirements.

Applications of container type grout injection pump:

Tunnel Construction: Used for stabilizing the surrounding ground, filling voids, and preventing water ingress during tunnel excavation.

Mining: Employed to stabilize underground workings, prevent cave-ins, and seal fractures in the rock.

Underground Engineering: Used in various underground construction projects, such as the construction of subways, utility tunnels, and storage facilities.

Selecting the right grouting pump is crucial to ensure the success of the project. The most suitable model and technical parameters need to be determined based on specific engineering requirements (such as the required pressure range, flow rate, operability and budget constraints). Any need please contact us by Email, address: sales1@leadcrete.com