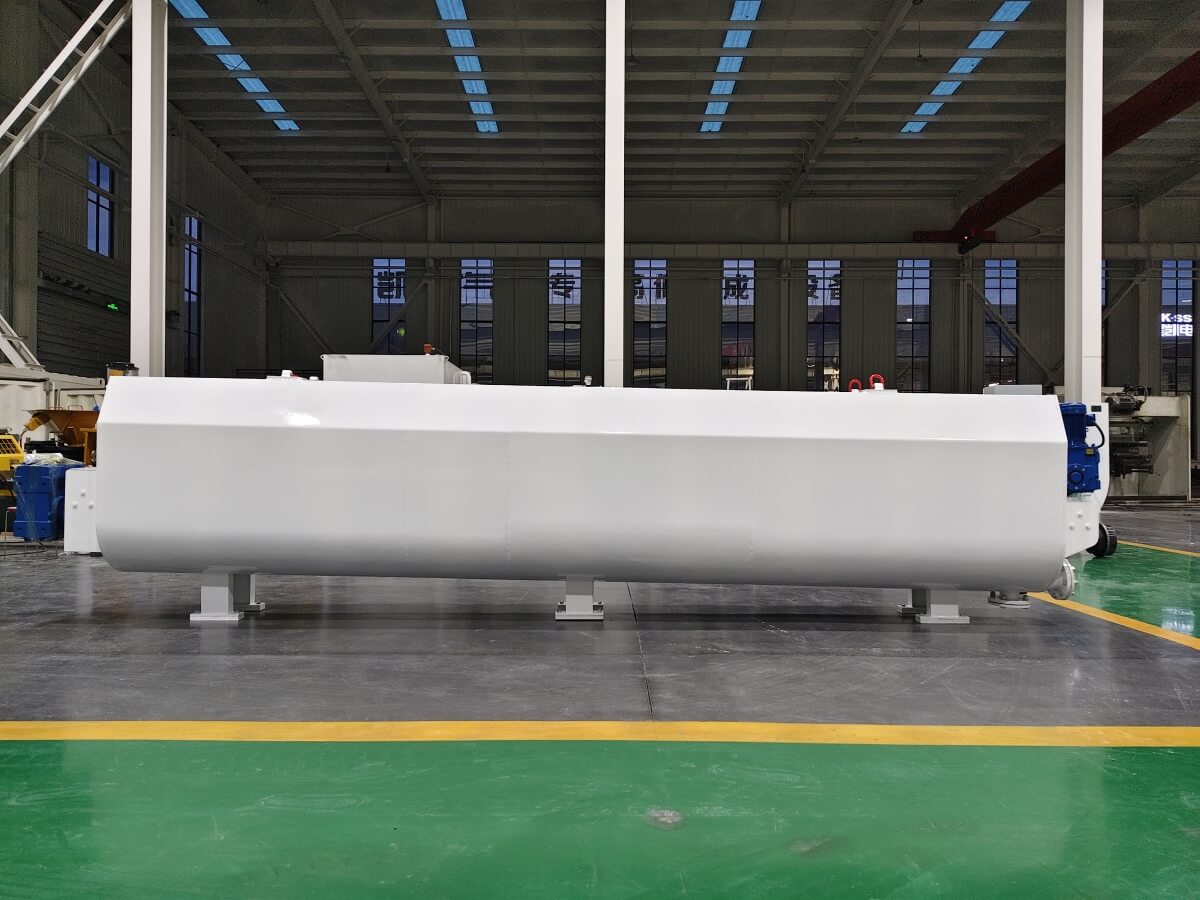

Industrial Hose Peristaltic Pump for Grout Mortar Slurry

Industrial Hose Peristaltic Pumps for Grout Mortar Slurry are specially designed to handle mortar materials that contain solid particles, high viscosity and may be corrosive. These pumps are widely used in construction, repair projects, tunnel construction and underground projects because they can reliably transfer difficult-to-handle media and have relatively low maintenance costs.

Industrial Hose Peristaltic Pump for Grout Mortar Slurry Application Cases:

Construction: In infrastructure construction, bridges and high-rise buildings, mortar slurry is used to transport mortar slurry to designated locations to ensure the quality of structural filling.

Repair and reinforcement: For repair and reinforcement work on existing buildings, mortar slurry can be accurately transported to cracks or gaps through hose pumps.

Tunnel construction: During the tunnel lining process, mortar slurry is injected into the surrounding rock gaps using a pump to enhance tunnel stability.

Industrial Hose Peristaltic Pump plays an important role in the delivery of grouting, mortar and mud. Industrial Hose Peristaltic Pump is particularly suitable for the delivery of media such as grouting, mortar and mud. These media are usually characterized by high viscosity, easy precipitation, and containing solid particles, and Industrial Hose Peristaltic Pump can stably and continuously deliver these media to ensure construction quality and efficiency.

Industrial Hose Peristaltic Pump drives the hose to extrude and deform through the rotation of the rotor in the pump body, thereby achieving the delivery of the medium. During each rotation of the rotor, the hose is squeezed by two rollers, so that the medium in the hose is squeezed and delivered to the outlet. When the roller leaves the hose, the hose returns to its original state and sucks in new media from the inlet. This working principle makes the Industrial Hose Peristaltic Pump self-priming and can handle high-viscosity media containing solid particles.

Industrial Hose Peristaltic Pumps for Grout Mortar Slurry is specially designed to handle mortar materials that contain solid particles, high viscosity and may be corrosive. These pumps are widely used in construction, repair projects, tunnel construction and underground projects because they can reliably transfer difficult-to-handle media and have relatively low maintenance costs. Application Cases Construction: In infrastructure construction, bridges and high-rise buildings, mortar slurry is used to transport mortar slurry to designated locations to ensure the quality of structural filling. Repair and reinforcement: For repair and reinforcement work on existing buildings, mortar slurry can be accurately transported to cracks or gaps through hose pumps. Tunnel construction: During the tunnel lining process, mortar slurry is injected into the surrounding rock gaps using a pump to enhance tunnel stability. If you are looking for an industrial hose peristaltic pump suitable for conveying mortar slurry, it is recommended to contact a professional manufacturer directly, such as Leadcrete Equipment. Email address: sales1@leadcrete.com