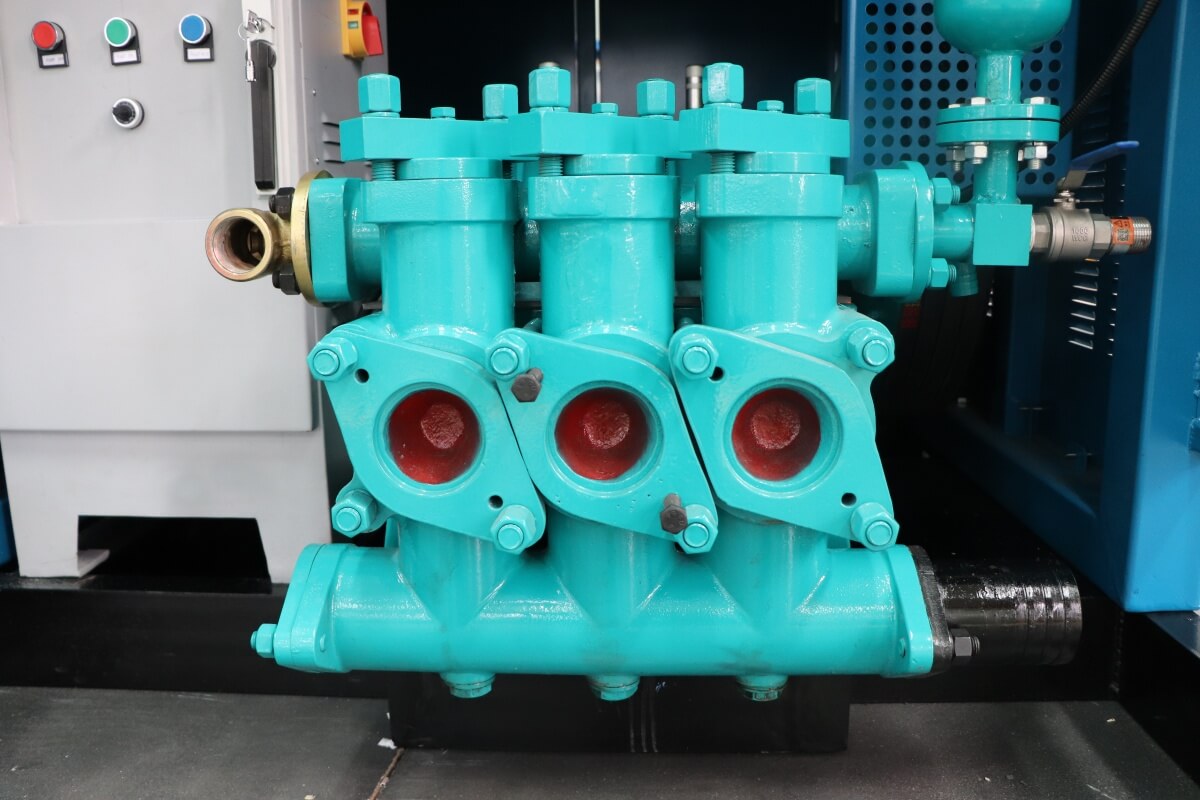

Today, a customized high-pressure triple jet grouting pump was successfully loaded and shipped to the UAE. This equipment will operate in conjunction with a local drilling rig, providing key support for foundation reinforcement and anti-seepage curtains for major infrastructure projects in the UAE. Jet grouting is a versatile geotechnical technique that modifies in-situ soils by injecting high-pressure cementitious slurry to create rigid, low-permeability soil-cement columns or barriers.

Located in the desert-coastal transition zone, the UAE has soft soil and a high groundwater table, placing stringent demands on jet grouting equipment. Below are its best uses, expanded with technical context and real-world scenarios:

1. Foundation Reinforcement

Purpose: Strengthen weak or unstable soils to improve load-bearing capacity for structures.

Mechanism:

High-pressure slurry (cement + water + additives) erodes and mixes with soft soil (e.g., clay, silt, loose sand).

Forms soil-cement columns (diameter: 0.5–1.5 m, depth: up to 30 m) that act as rigid piles.

Applications:

Building Foundations: Supports high-rise buildings, bridges, or industrial facilities on compressible/soft soils.

Slope Stability: Reinforces embankments or natural slopes prone to failure.

Liquefaction Mitigation: In earthquake zones, reduces soil liquefaction risk by densifying and stabilizing loose sands.

2. Excavation Support & Soil Retention

Purpose: Stabilize soil during deep excavations and prevent collapse.

Mechanism:

Jet grout columns form a retaining wall or cutoff barrier around excavation perimeters.

Slurry pressure balances earth and hydrostatic pressures.

Applications:

Deep Basements: Creates waterproof walls for underground parking or facilities.

Tunnel Portals: Stabilizes soil ahead of tunnel boring machines (TBMs).

Shaft Construction: Forms impermeable linings for mine/utility shafts.

Coastal/River Structures: Protects against erosion during bridge/pier construction.

3. Seepage & Groundwater Control

Purpose: Block water flow through soils to prevent flooding, piping, or contamination.

Mechanism:

Low-permeability soil-cement barriers (permeability: 10⁻⁶–10⁻⁸ cm/s) reduce hydraulic conductivity.

Applications:

Dam Foundations: Seals leak-prone zones in earth/rockfill dams.

Landfill Liners: Creates impermeable barriers beneath waste containment facilities.

Tunnel Linings: Stops groundwater inflow into subway/rail tunnels.

Dewatering: Reduces groundwater drawdown impacts during excavation.

4. Seismic Retrofitting & Liquefaction Mitigation

Purpose: Enhance soil resilience in earthquake-prone regions.

Mechanism:

Jet grouting densifies loose sands and binds soil particles, increasing shear strength and reducing liquefaction potential.

Applications:

Retrofitting Existing Structures: Strengthens foundations of bridges, dams, or historic buildings.

Critical Infrastructure: Protects hospitals, power plants, or emergency facilities from seismic damage.

Urban Areas: Mitigates liquefaction risks in cities built on reclaimed land or alluvial deposits.

If you are also interested in our LGP440/50PI-22E high pressure triplex jet grout pump for sale for drilling, if you are interested, please contact us directly at sales1@leadcrete.com.

Your position:

Home > News > Product News

High pressure triplex jet grout pump for sale

date: 2025-08-08

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)