Your position:

Home > Products > Foam Concrete Machine

LA40 Concrete foam agent

Put this concrete foam agent into concrete, it is a product with moisture retention, impermeability, moisture retention, light weight and sound insulation.

Light yellow pure transparent oily liquid

1.06

6.8-7.2

<=0.5%

>=40%

<=50

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

Our concrete foaming agent is made of vegetable oil and protein, non-toxic, harmless and non combustible. It is also an environmentally friendly material. In addition to conventional ingredients, we also added some special ingredients to make foam more stable and foam concrete more solid.

LA40 cement foaming agent is a high-tech product; It has the characteristics of high expansion rate, balanced density, good foaming stability and long duration. It is a non-toxic, tasteless, pollution-free and environmentally friendly strong foaming agent.

Foaming agent, also known as foam concrete foaming agent, is an additive that can reduce the surface tension of liquid and produce a large amount of uniform and stable foam, which is used to produce foam concrete.

Concrete foam agent is a kind of substance. When the mechanical force is introduced into the air, its aqueous solution can produce a large amount of foam. Such substances are surfactants or surface active substances. The essence of foam agent is its surface activity. If there is no surfactant, it can not be foamed and become a foaming agent. Surface activity is the core of foaming.

There are usually two types of blowing foam agents. One is foam agent in a broad sense, and the other is foam agent in a narrow sense. In a broad sense, foaming agent refers to all surfactants or surface active substances, whose aqueous solution can produce a large amount of foam when introduced into air. There are no strict requirements for its technical properties such as foaming times and foam stability. This only shows that it has a certain ability to produce a large amount of foam. Whether the produced foam can be used for practical purposes has not been defined.

Foam concrete additive in a narrow sense refers to a foaming agent that can not only produce a large amount of foam, but also has excellent performance and can meet the foaming technical requirements of various products. They can indeed be used to produce actual surfactants or surface active substances. The foaming ability is particularly strong. The output of foam per unit volume is large. The foam is very stable and cannot be defoaming for a long time. The foam is fine and has good compatibility with the medium used. The latter is a foaming agent that is actually used in industry. In general, a blowing agent is narrowly defined as a blowing agent.

The cement foaming agent used in foam concrete is used for foaming concrete. In addition to producing large foam, it also pays special attention to the stability of foam, the fineness of foam and the adaptability of foam and cement and other cementitious materials. There are also some narrow range of foam agents that can meet this requirement. Most foaming agents can not be used in the actual production of foam concrete. Therefore, the foaming agent of foam concrete must be several surfactants or surface active substances that meet the above technical requirements.

At present, many water injection foam concrete products in the market have very high water absorption, some of which are even as high as 50%. The reason is that the closed porosity of foam concrete is low, and through holes are formed due to the poor foam stability of foam and aircrete foaming agent foam. This is because aircrete foaming agent has a low closed cell rate, so a good aircrete foaming agent is a foaming agent that can make foam concrete products have a low water absorption.

As for our aircrete foaming agent, its main component is plant protein, which is a transparent liquid. Non toxic, no sediment, non corrosive to cement and metal, environmental friendly and easy to store. The warranty period is 3 years. It has excellent foaming characteristics and foam stability.

Cement foaming agent is the key material for producing foam concrete. Whether foam concrete with proper density can be produced depends on the selection of proper cement foaming agent. There are many types of cement foaming agents in the market, and the prices of foaming machines vary greatly. Many people blindly choose blowing agents or choose the ones with lower prices. In fact, the price of foaming agent in foam concrete is the lowest, so we do not want to choose cement foaming agent based on the price alone.

There are many types of cement foaming agents on the market. These types of blowing agents have their own advantages and disadvantages, and the price of each barrel of blowing agent is different. In the eyes of many people, cement foaming agent can only foam and densify, which is very one-sided. The cement foaming agent is actually related to the strength, thermal conductivity, setting speed, water absorption and pouring height of foam concrete products. Therefore, when selecting cement blowing agent, not only the price of blowing agent but also the overall cost should be considered. The cost of cement in foam concrete is the main cost.

Leadcrete machinery, a manufacturer of concrete foam agent, strictly monitors the product quality according to the quality standards to achieve a win-win situation with customers and ensure that the product quality fully meets the requirements of customers. Please contact us for more information: sales1@leadcrete.com.

LA40 cement foaming agent is a high-tech product; It has the characteristics of high expansion rate, balanced density, good foaming stability and long duration. It is a non-toxic, tasteless, pollution-free and environmentally friendly strong foaming agent.

Foaming agent, also known as foam concrete foaming agent, is an additive that can reduce the surface tension of liquid and produce a large amount of uniform and stable foam, which is used to produce foam concrete.

Concrete foam agent is a kind of substance. When the mechanical force is introduced into the air, its aqueous solution can produce a large amount of foam. Such substances are surfactants or surface active substances. The essence of foam agent is its surface activity. If there is no surfactant, it can not be foamed and become a foaming agent. Surface activity is the core of foaming.

There are usually two types of blowing foam agents. One is foam agent in a broad sense, and the other is foam agent in a narrow sense. In a broad sense, foaming agent refers to all surfactants or surface active substances, whose aqueous solution can produce a large amount of foam when introduced into air. There are no strict requirements for its technical properties such as foaming times and foam stability. This only shows that it has a certain ability to produce a large amount of foam. Whether the produced foam can be used for practical purposes has not been defined.

Foam concrete additive in a narrow sense refers to a foaming agent that can not only produce a large amount of foam, but also has excellent performance and can meet the foaming technical requirements of various products. They can indeed be used to produce actual surfactants or surface active substances. The foaming ability is particularly strong. The output of foam per unit volume is large. The foam is very stable and cannot be defoaming for a long time. The foam is fine and has good compatibility with the medium used. The latter is a foaming agent that is actually used in industry. In general, a blowing agent is narrowly defined as a blowing agent.

The cement foaming agent used in foam concrete is used for foaming concrete. In addition to producing large foam, it also pays special attention to the stability of foam, the fineness of foam and the adaptability of foam and cement and other cementitious materials. There are also some narrow range of foam agents that can meet this requirement. Most foaming agents can not be used in the actual production of foam concrete. Therefore, the foaming agent of foam concrete must be several surfactants or surface active substances that meet the above technical requirements.

At present, many water injection foam concrete products in the market have very high water absorption, some of which are even as high as 50%. The reason is that the closed porosity of foam concrete is low, and through holes are formed due to the poor foam stability of foam and aircrete foaming agent foam. This is because aircrete foaming agent has a low closed cell rate, so a good aircrete foaming agent is a foaming agent that can make foam concrete products have a low water absorption.

As for our aircrete foaming agent, its main component is plant protein, which is a transparent liquid. Non toxic, no sediment, non corrosive to cement and metal, environmental friendly and easy to store. The warranty period is 3 years. It has excellent foaming characteristics and foam stability.

Cement foaming agent is the key material for producing foam concrete. Whether foam concrete with proper density can be produced depends on the selection of proper cement foaming agent. There are many types of cement foaming agents in the market, and the prices of foaming machines vary greatly. Many people blindly choose blowing agents or choose the ones with lower prices. In fact, the price of foaming agent in foam concrete is the lowest, so we do not want to choose cement foaming agent based on the price alone.

There are many types of cement foaming agents on the market. These types of blowing agents have their own advantages and disadvantages, and the price of each barrel of blowing agent is different. In the eyes of many people, cement foaming agent can only foam and densify, which is very one-sided. The cement foaming agent is actually related to the strength, thermal conductivity, setting speed, water absorption and pouring height of foam concrete products. Therefore, when selecting cement blowing agent, not only the price of blowing agent but also the overall cost should be considered. The cost of cement in foam concrete is the main cost.

Leadcrete machinery, a manufacturer of concrete foam agent, strictly monitors the product quality according to the quality standards to achieve a win-win situation with customers and ensure that the product quality fully meets the requirements of customers. Please contact us for more information: sales1@leadcrete.com.

Application

Concrete foam agent is applicable to the application of foam concrete such as CLC block, light wallboard, floor heating, roof insulation and prefabrication.

GD composite concrete foaming agent is especially used for composite processing and deformation. When mixed with water, a large number of cement slurry bubbles will be generated, which are independent of each other and evenly distributed in the slurry or water.

Main raw materials: GD foaming agent mainly uses pollution-free vegetable oil and animal protein. It will not have any negative impact on producers, users or the environment, and greatly improve the quality of human life.

Foaming stability: GD composite foaming agent, with high stability of bubble bag, shows high specific three-dimensional tension and ductile stretching, supports bubbles before final setting of cement slurry, maintains the original state of pores, and is transported to the high-rise (above 40 floors) by high-pressure transmission pump without defoaming or even collapse.

Foam concrete, also known as porous lightweight concrete, is widely used in the construction industry in many countries, such as the Philippines, India, the United States, Germany and so on. Of course, foam concrete is becoming more and more popular.

The strength of cast-in-situ foam concrete can be effectively improved by choosing a good foaming agent. A good aircrete foaming agent can form a bright closed cell in foam concrete, thus greatly improving the density and strength of foam wall. Good aircrete blowing agent can be used at low water cement ratio, the lower the water cement ratio, the higher the strength.

At present, many aircrete blowing agents in the market can only be used under high water cement ratio. This is why many construction teams use high water cement ratio construction. It looks like porridge. It can also be said to be self leveling. At the cost of sacrificing the strength of foam concrete, it has become a "bean curd dregs project".

It is mainly used for producing floor heating foam concrete insulation layer, foam concrete sound insulation and insulation cushion. Suitable for cement, magnesia, lime, gypsum, stone powder, sawdust, fly ash, sand, paper sludge and various raw materials. Foam is made of foam concrete, partitions, slats, blocks, solid bricks, hollow bricks, thermal insulation sleeves, roof insulation panels and other lightweight foam building materials, and can also be used for roof insulation production.

How to make concrete foaming agent:

The concentration of concrete additive is generally large, and it needs to be diluted with a certain proportion of water to form a foaming liquid, which is then foamed. Pour water and foaming agent into the water tank to completely dissolve. After observing the bubbles, pour the prepared cement into the tank, and then use the mixing tool to fully mix, and then send it to the wallboard machine through the high-pressure conveying pipe or manually to process it into finished products. Foam chemical is mainly used to produce light partition board, thermal insulation, sound insulation materials, foam cement bricks, etc. Foam concrete machine and foaming agent are a coordinated technical system. They cannot function alone, and no one can do without them.

GD composite concrete foaming agent is especially used for composite processing and deformation. When mixed with water, a large number of cement slurry bubbles will be generated, which are independent of each other and evenly distributed in the slurry or water.

Main raw materials: GD foaming agent mainly uses pollution-free vegetable oil and animal protein. It will not have any negative impact on producers, users or the environment, and greatly improve the quality of human life.

Foaming stability: GD composite foaming agent, with high stability of bubble bag, shows high specific three-dimensional tension and ductile stretching, supports bubbles before final setting of cement slurry, maintains the original state of pores, and is transported to the high-rise (above 40 floors) by high-pressure transmission pump without defoaming or even collapse.

Foam concrete, also known as porous lightweight concrete, is widely used in the construction industry in many countries, such as the Philippines, India, the United States, Germany and so on. Of course, foam concrete is becoming more and more popular.

The strength of cast-in-situ foam concrete can be effectively improved by choosing a good foaming agent. A good aircrete foaming agent can form a bright closed cell in foam concrete, thus greatly improving the density and strength of foam wall. Good aircrete blowing agent can be used at low water cement ratio, the lower the water cement ratio, the higher the strength.

At present, many aircrete blowing agents in the market can only be used under high water cement ratio. This is why many construction teams use high water cement ratio construction. It looks like porridge. It can also be said to be self leveling. At the cost of sacrificing the strength of foam concrete, it has become a "bean curd dregs project".

It is mainly used for producing floor heating foam concrete insulation layer, foam concrete sound insulation and insulation cushion. Suitable for cement, magnesia, lime, gypsum, stone powder, sawdust, fly ash, sand, paper sludge and various raw materials. Foam is made of foam concrete, partitions, slats, blocks, solid bricks, hollow bricks, thermal insulation sleeves, roof insulation panels and other lightweight foam building materials, and can also be used for roof insulation production.

How to make concrete foaming agent:

The concentration of concrete additive is generally large, and it needs to be diluted with a certain proportion of water to form a foaming liquid, which is then foamed. Pour water and foaming agent into the water tank to completely dissolve. After observing the bubbles, pour the prepared cement into the tank, and then use the mixing tool to fully mix, and then send it to the wallboard machine through the high-pressure conveying pipe or manually to process it into finished products. Foam chemical is mainly used to produce light partition board, thermal insulation, sound insulation materials, foam cement bricks, etc. Foam concrete machine and foaming agent are a coordinated technical system. They cannot function alone, and no one can do without them.

Features

Features of LA40 Concrete foam agent:

1. It is non-toxic, harmless, non combustible, and free of sediment. It is safe for human body and friendly to the environment.

2. It is liquid and easy to transport and use.

3. It is non corrosive to cement and metal, environmentally friendly and easy to store, with long shelf life.

4. Foam agent is a natural foam agent with concentrated enzyme active components.

5. When diluted in water and treated with compressed air in foam generator, stable foam can be produced.

6. It is widely used in the building materials industry and other construction industries.

Influence of cement foaming agent on properties of foam concrete:

1. Strength

The strength of foam concrete is a key index. How to improve the strength of foam concrete becomes the key factor to improve the performance of foam concrete. The strength of foam concrete can be effectively improved by choosing proper cement foaming agent. A good cement foaming agent can form bright closed pores in foam concrete, thus greatly improving the density of foam wall and thus improving the strength.

2. Water absorption

At present, many foam concrete products in the market have very high water absorption, some even as high as 50%. The reason is that the closed cell rate of foam concrete is low, and through holes are formed due to the foaming of cement foaming agent and poor foam stability. This is because the cement foaming agent has a low closed cell rate, so a good cement foaming agent can make foam concrete products have low water absorption.

3. Pouring height

The pouring height of foam concrete is directly related to the stability of foam of cement foaming agent. The cement foaming agent has high foam stability, and the higher the pouring height, and vice versa. The higher the pouring height, the greater the pressure of mud on foam. If the foam is not stable, it will collapse.

4. Density

The key to the density control of foam concrete is the amount of foam, so the direct factor affecting the density is cement foaming agent. The more stable the foam of cement foaming agent, the better the density control, and the lower the density of foam concrete. On the contrary, the stability of the cement foaming agent is not good. The density can be designed to be 400 kg, and the density during pouring is 500 kg. The upper density and the lower density may also be different, that is, the density is not uniform. This problem is more obvious on Wall Street.

5. Thermal conductivity

The most direct factor affecting the thermal conductivity is the density of foam concrete, and the key factor of density control is cement foaming agent.

To sum up, cement foaming agent will affect the strength, water absorption, pouring height, density and thermal conductivity of foam concrete. Therefore, it is very important to select high-quality foaming agent in foam concrete construction. uction.

1. It is non-toxic, harmless, non combustible, and free of sediment. It is safe for human body and friendly to the environment.

2. It is liquid and easy to transport and use.

3. It is non corrosive to cement and metal, environmentally friendly and easy to store, with long shelf life.

4. Foam agent is a natural foam agent with concentrated enzyme active components.

5. When diluted in water and treated with compressed air in foam generator, stable foam can be produced.

6. It is widely used in the building materials industry and other construction industries.

Influence of cement foaming agent on properties of foam concrete:

1. Strength

The strength of foam concrete is a key index. How to improve the strength of foam concrete becomes the key factor to improve the performance of foam concrete. The strength of foam concrete can be effectively improved by choosing proper cement foaming agent. A good cement foaming agent can form bright closed pores in foam concrete, thus greatly improving the density of foam wall and thus improving the strength.

2. Water absorption

At present, many foam concrete products in the market have very high water absorption, some even as high as 50%. The reason is that the closed cell rate of foam concrete is low, and through holes are formed due to the foaming of cement foaming agent and poor foam stability. This is because the cement foaming agent has a low closed cell rate, so a good cement foaming agent can make foam concrete products have low water absorption.

3. Pouring height

The pouring height of foam concrete is directly related to the stability of foam of cement foaming agent. The cement foaming agent has high foam stability, and the higher the pouring height, and vice versa. The higher the pouring height, the greater the pressure of mud on foam. If the foam is not stable, it will collapse.

4. Density

The key to the density control of foam concrete is the amount of foam, so the direct factor affecting the density is cement foaming agent. The more stable the foam of cement foaming agent, the better the density control, and the lower the density of foam concrete. On the contrary, the stability of the cement foaming agent is not good. The density can be designed to be 400 kg, and the density during pouring is 500 kg. The upper density and the lower density may also be different, that is, the density is not uniform. This problem is more obvious on Wall Street.

5. Thermal conductivity

The most direct factor affecting the thermal conductivity is the density of foam concrete, and the key factor of density control is cement foaming agent.

To sum up, cement foaming agent will affect the strength, water absorption, pouring height, density and thermal conductivity of foam concrete. Therefore, it is very important to select high-quality foaming agent in foam concrete construction. uction.

Product Details

Technical Parameters

Technical Data

| Item | Specifications | |

| Appearance | Light yellow pure transparent oily liquid | |

| Density(kg/L) | 1.06 | |

| PH value | 6.8-7.2 | |

| Content of inorganic salts | <=0.5% | |

| Water absorption | >=40% | |

| Color(APHA) | <=50 | |

| Consumption(kg/m3) | 0.35-0.45 | |

| Temperature(℃) | >=5 | |

| Safety | Chemically inactive, non-toxic, odorless, non-flammables | |

| Weight(kg) | Small barrel | 50 |

| Big barrel | 200 | |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine for Sale

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine for Sale -

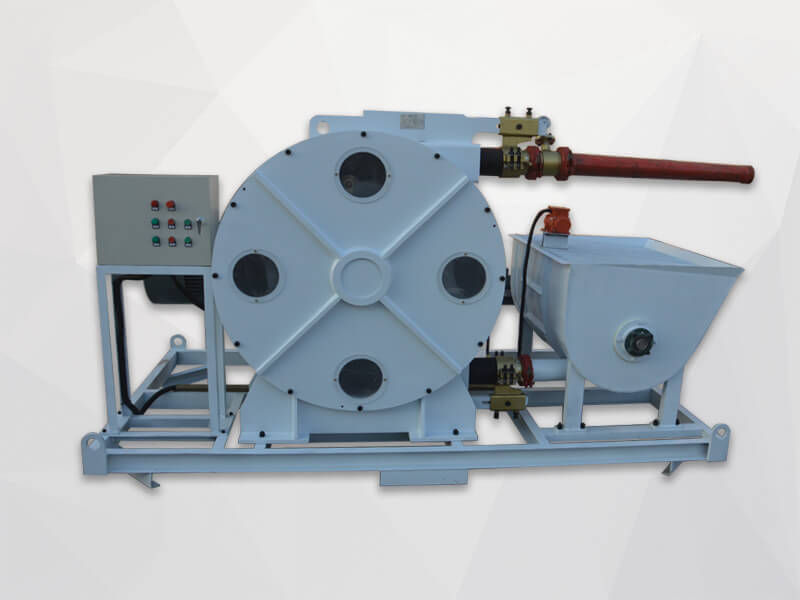

LP30 precast foam cement wall panel machine puts cement and water into a slurry mixing and then mix them in a certain proportion, press them into transmission pipelines through hydraulic cylinder: According to a certain proportion foam mixed with water and then mixed with compressed air by the high-pressure pump: In the pipeline it form the high-densit foam and meticulous, at last form the foam cement with the slurry in the pipeline.LP30 Precast Foam Cement Wall Panel Machine

LP30 precast foam cement wall panel machine puts cement and water into a slurry mixing and then mix them in a certain proportion, press them into transmission pipelines through hydraulic cylinder: According to a certain proportion foam mixed with water and then mixed with compressed air by the high-pressure pump: In the pipeline it form the high-densit foam and meticulous, at last form the foam cement with the slurry in the pipeline.LP30 Precast Foam Cement Wall Panel Machine -

LF20 CLC brick making machine is a medium-sized foamed concrete brick making machine based on many years of experience, with completely independent intellectual property rights.LF20 CLC Making Machine

LF20 CLC brick making machine is a medium-sized foamed concrete brick making machine based on many years of experience, with completely independent intellectual property rights.LF20 CLC Making Machine -

LF10B aircrete machine for sale is a self-developed patented product. It adopts advanced control technology to continuously and accurately adjust the density of foamed cement. It can also meet the production of foamed concrete products with different densities. The output is 10 cubic meters per hour. Loading operation. LF10B aircrete machine for sale is easy to operate and easy to move. It has continuous feeding and water supply systems, high pumping height and low power requirements.LF10B Aircrete Machine for Sale

LF10B aircrete machine for sale is a self-developed patented product. It adopts advanced control technology to continuously and accurately adjust the density of foamed cement. It can also meet the production of foamed concrete products with different densities. The output is 10 cubic meters per hour. Loading operation. LF10B aircrete machine for sale is easy to operate and easy to move. It has continuous feeding and water supply systems, high pumping height and low power requirements.LF10B Aircrete Machine for Sale

.jpg)

.jpg)