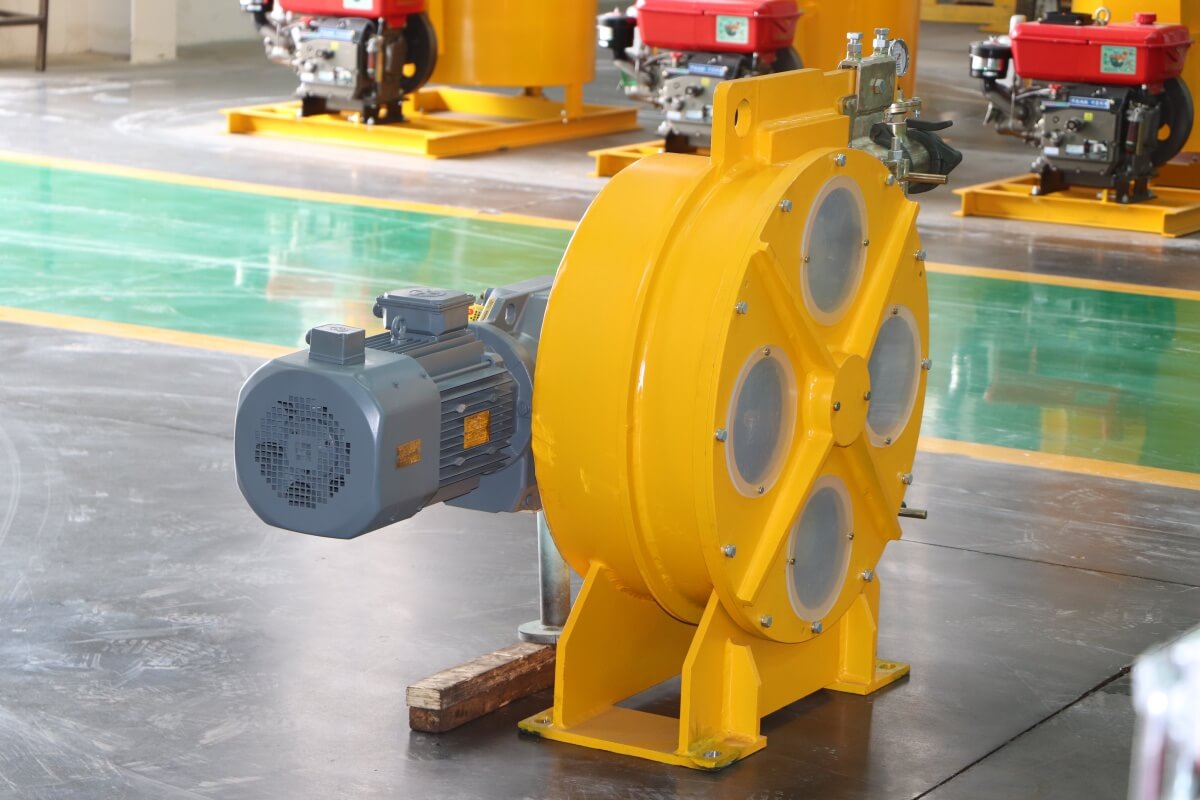

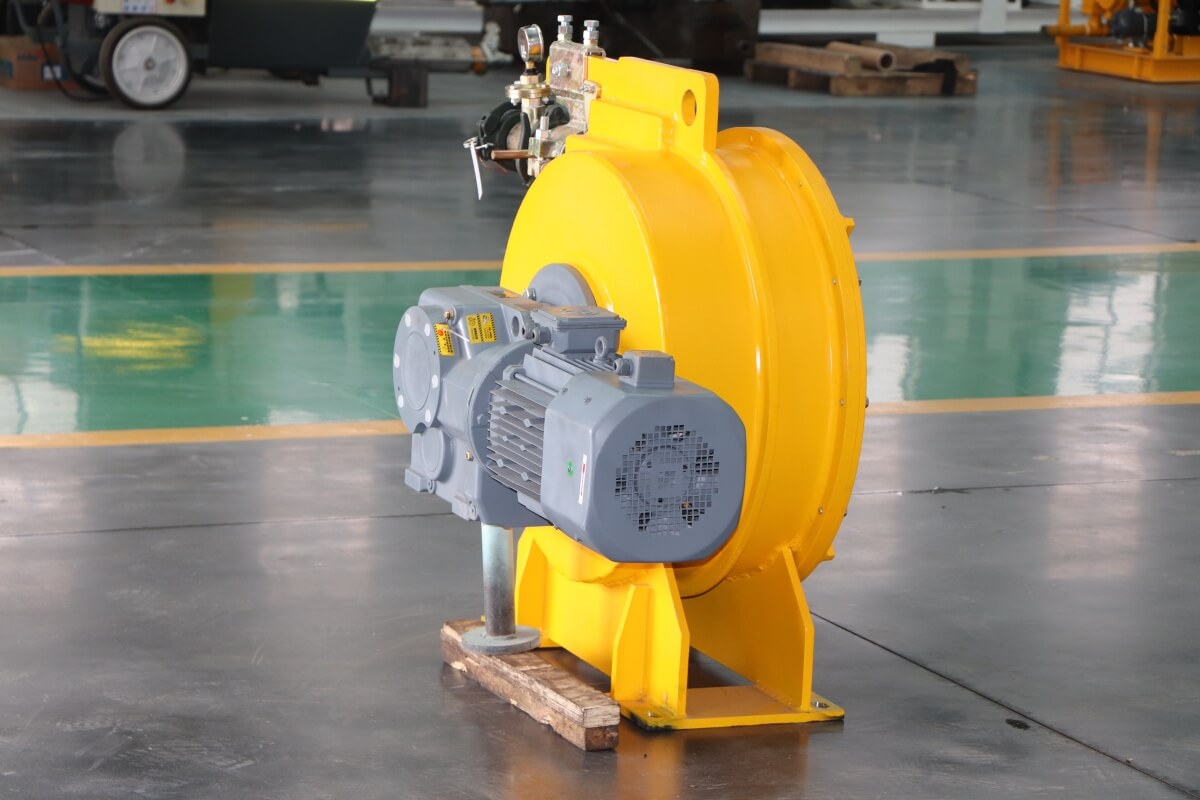

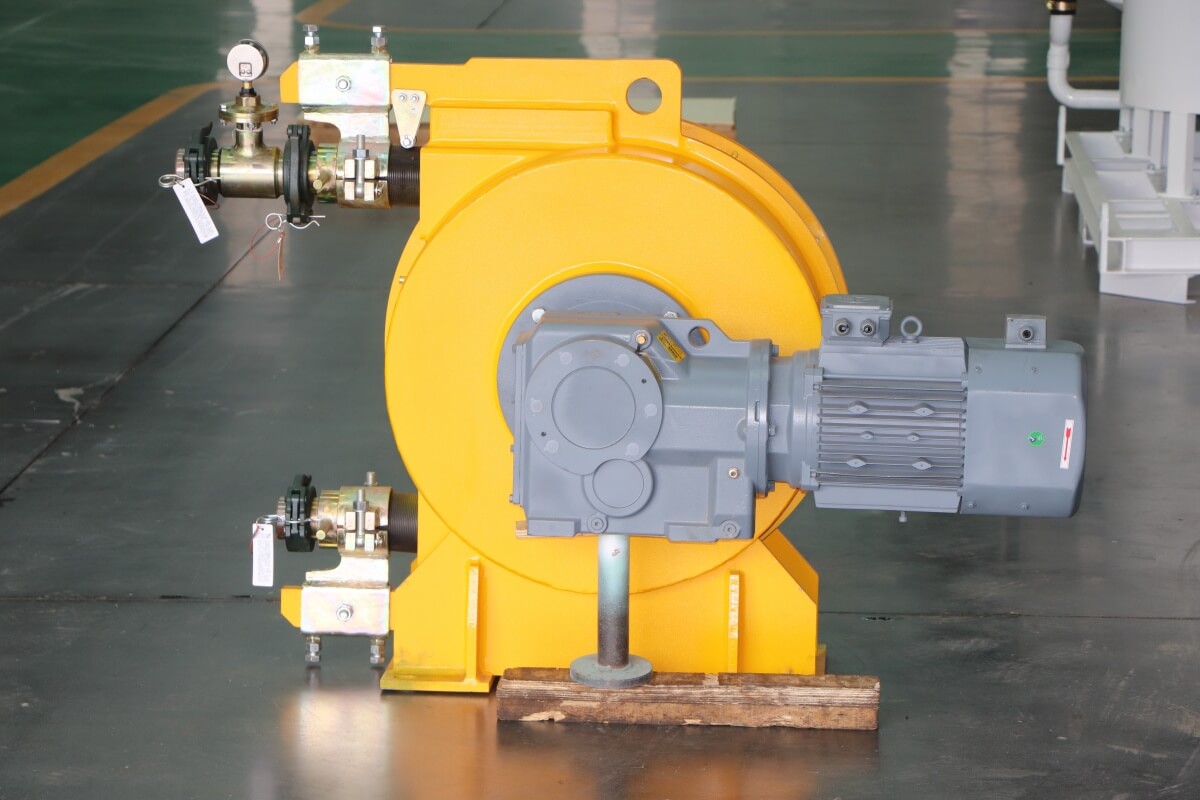

Peristaltic concrete pump for precast concrete plant

For precast concrete plants, peristaltic pumps offer a reliable, low-maintenance solution for handling abrasive, viscous concrete mixes. Their ability to deliver precise, pulsation-free flow reduces waste, improves product quality, and lowers operational costs—making them a preferred choice for high-output precast facilities. When selecting a pump, prioritize hose durability, drive system reliability, and integration with plant automation.

Peristaltic concrete pump for precast concrete plant applications:

Peristaltic pumps are ideal for:

1. Filling Molds: Precise delivery of concrete into complex molds (e.g., hollow-core slabs, double walls).

2. Casting Small Elements: Efficient production of staircases, balconies, or architectural cladding.

3. 3D Concrete Printing: Continuous extrusion for layered construction, where pulsation-free flow is critical.

4. Grouting & Anchoring: Pumping high-strength grout for post-tensioning or anchor bolts.

Key Advantages for Precast Concrete Plants:

Abrasion Resistance:

Concrete is highly abrasive due to aggregates (sand, gravel). Peristaltic pumps use durable, reinforced hoses (e.g., natural rubber, EPDM, or polyurethane) that withstand wear better than traditional piston or screw pumps, which rely on valves or seals that degrade quickly.

Handling Viscous & Aggressive Mixes:

They excel with stiff, self-compacting concrete (SCC) or mixes with high cement content, as the hose compression generates sufficient force without requiring high pressure (reducing wear on the pump and the concrete itself).

Dry Running & Self-Priming:

Peristaltic pumps can run dry without damage and self-prime, eliminating the need for manual priming—critical in precast plants where frequent start/stop cycles are common (e.g., filling multiple molds).

Low Maintenance:

Only the hose requires periodic replacement (typically every 500–2,000 m³ of concrete, depending on mix aggressiveness). There are no valves, pistons, or seals to replace, reducing downtime and maintenance costs.

Precise Flow Control:

Variable speed drives allow accurate dosing, essential for precast elements like walls, columns, or beams where consistent concrete volume ensures dimensional accuracy.

Reduced Pulsation:

Smooth, continuous flow minimizes vibration in molds, improving surface finish and reducing air entrapment in the concrete.