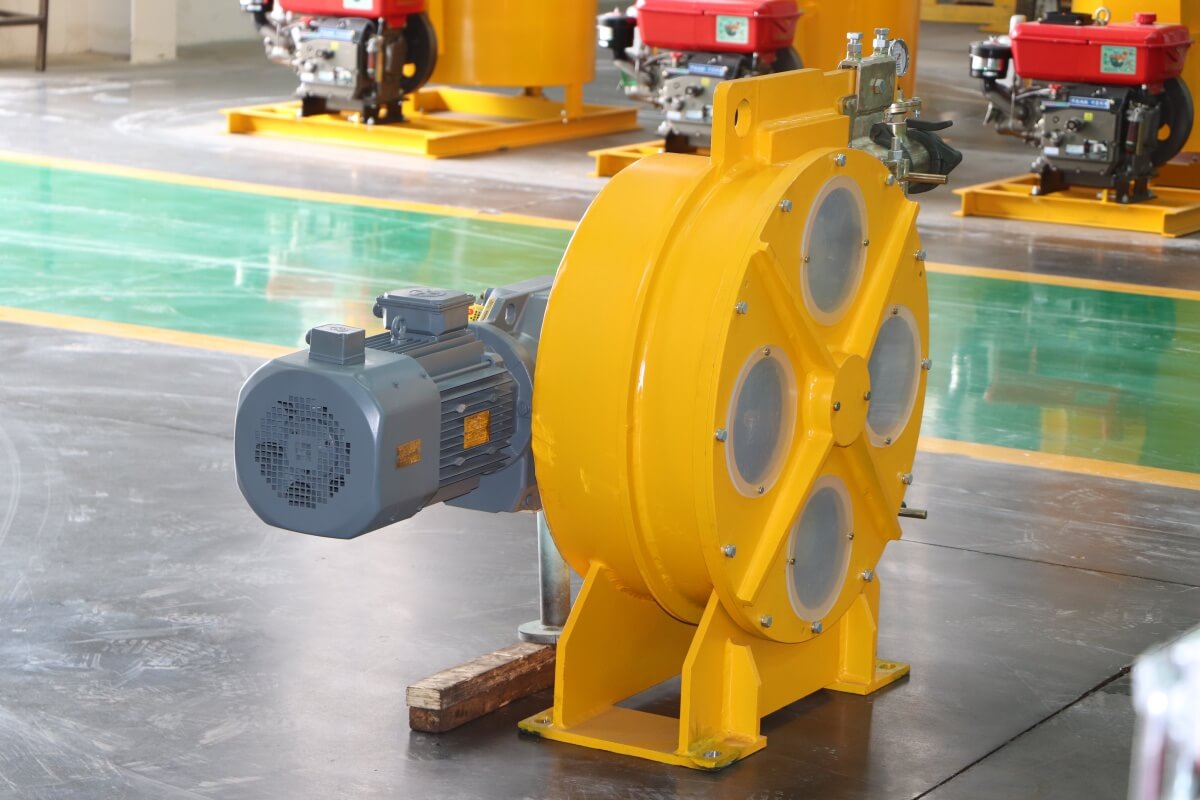

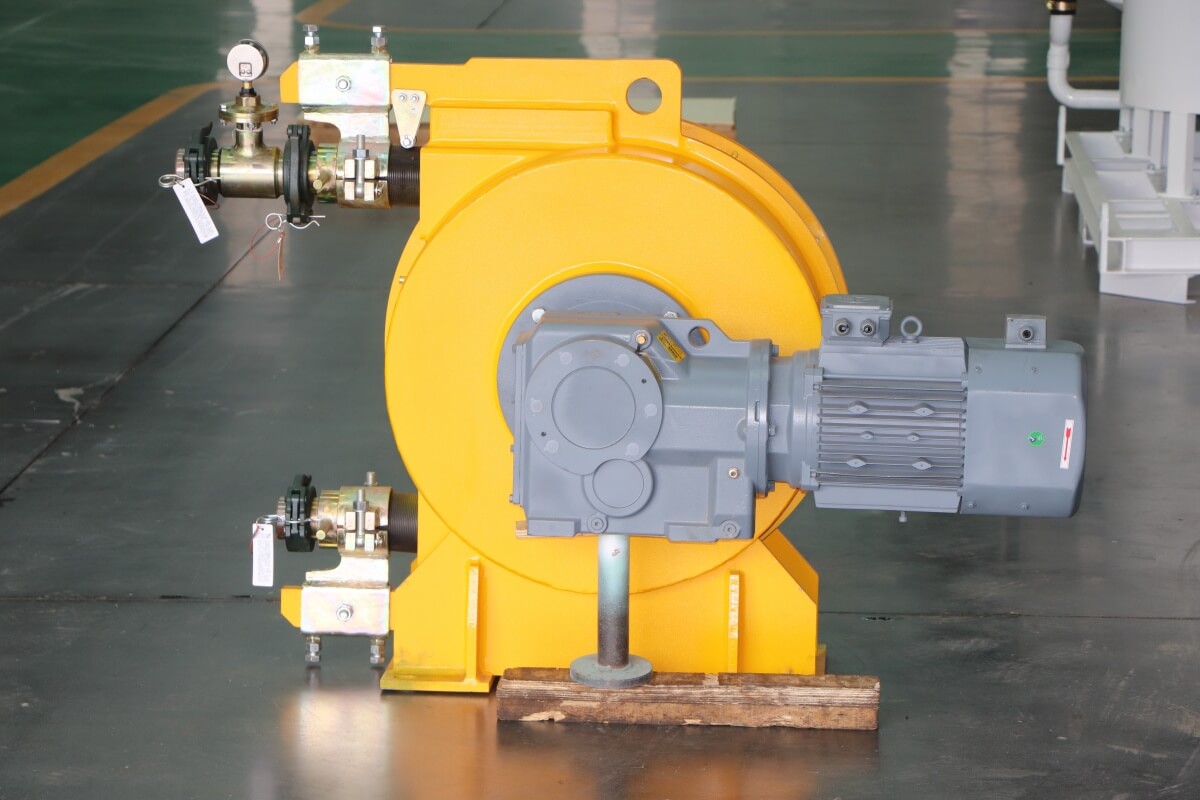

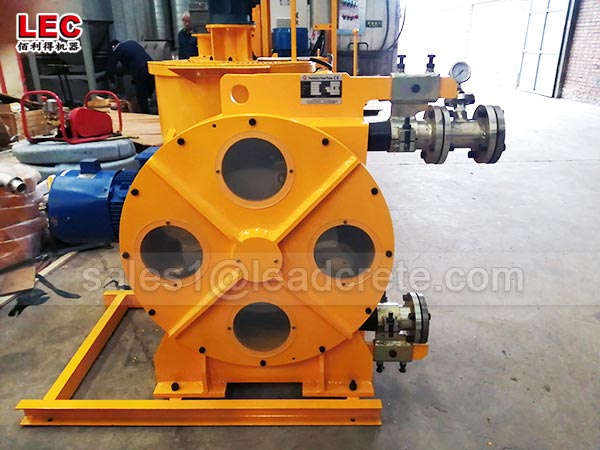

Peristaltic concrete pump

A peristaltic concrete pump (also called a squeeze pump or hose pump) is a specialized positive displacement pump designed to transport concrete, grout, or mortar in construction applications. Its unique operating principle—mimicking peristaltic motion (like intestinal contractions)—makes it ideal for handling abrasive, viscous, or shear-sensitive materials.

Peristaltic concrete pumps are widely used in:

Precast Concrete Plants: Filling molds (e.g., hollow-core slabs, walls) with consistent concrete volume.

3D Concrete Printing: Continuous extrusion for layered construction.

Grouting & Anchoring: Pumping high-strength grout for post-tensioning or anchor bolts.

Tunneling & Mining: Transporting shotcrete or backfill mixes in harsh environments.

Remote or Hazardous Sites: Self-priming and dry-running capabilities suit areas with limited access to water for priming.

How a peristaltic concrete pump works:

Flexible Hose: A reinforced, durable hose (typically made of natural rubber, EPDM, or polyurethane) is the pump’s core component.

Roller Mechanism: Rotating rollers (or shoes) press against the hose, compressing it sequentially.

Peristaltic Action: As the rollers move, they create a temporary seal, forcing the concrete through the hose in a smooth, pulsation-free flow.

Suction Phase: After compression, the hose returns to its original shape, drawing in more material via suction.

This design ensures gentle material handling (minimal segregation of aggregates) and low wear since only the hose contacts the concrete.

Peristaltic concrete pump Advantages:

Abrasion Resistance:

Ideal for concrete mixes with coarse aggregates (e.g., 16–20 mm), as the hose withstands abrasion better than piston/screw pump valves or seals.

Handles Stiff Mixes:

Excels with self-compacting concrete (SCC), high-slump mixes, or cementitious grouts that resist flow.

Dry Running & Self-Priming:

Can operate without concrete (dry) without damage and self-prime, eliminating manual priming—critical for intermittent use.

Low Maintenance:

Only the hose requires replacement (every 500–2,000 m³ of concrete). No valves, pistons, or seals to service.

Precise Flow Control:

Variable speed drives enable accurate dosing, essential for applications like precast molds or 3D concrete printing.

Pulsation-Free Flow:

Smooth delivery reduces vibration in molds, improving surface finish and minimizing air entrapment.