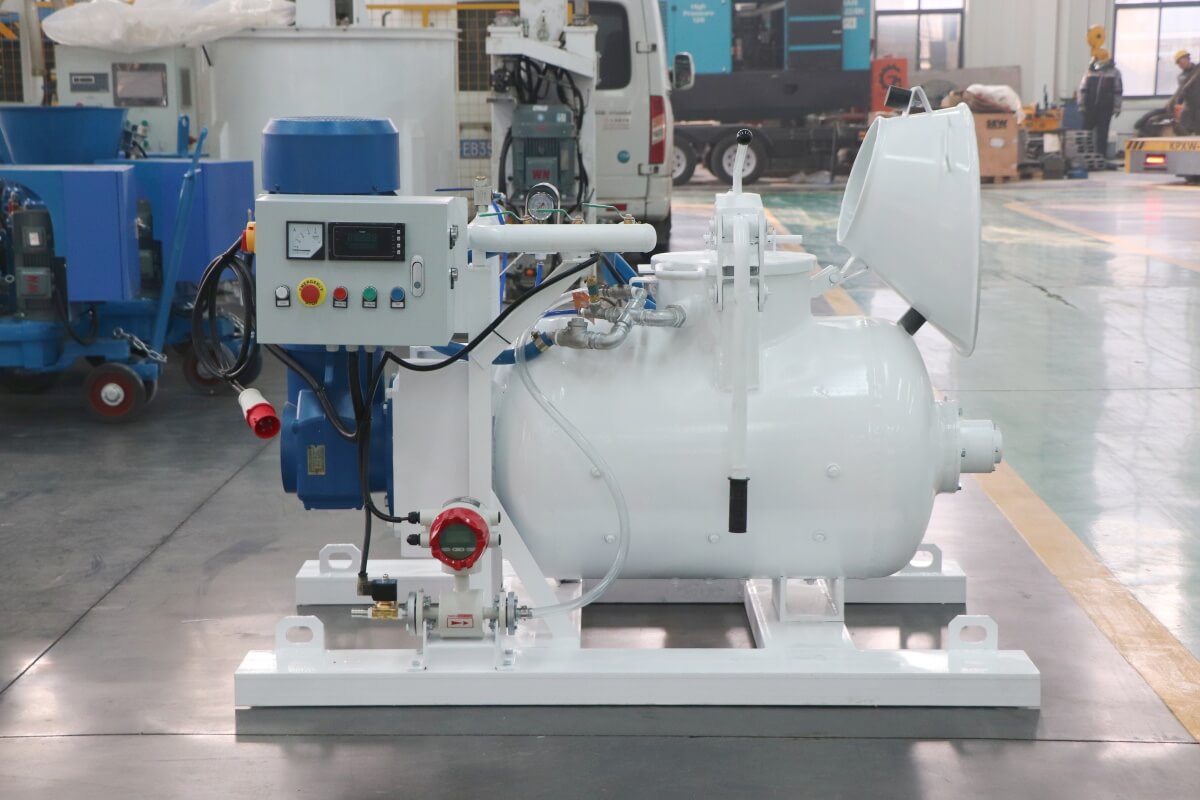

Refractory Gunning Machine for Boiler Chimney Lime Refractory Repairing

Refractory Gunning Machine is a special equipment used for repairing the refractory layer of high-temperature industrial equipment (such as boilers, chimneys, coke ovens, etc.). It uses high-pressure spraying to evenly cover the damaged surface with refractory materials (such as lime-based refractory mud) to form a new refractory layer. For the repair of lime-based refractory materials on boiler chimneys, it is necessary to select a gunning equipment suitable for lime-based materials.

Refractory Gunning Machine is an efficient tool for repairing boiler chimney lime refractory materials. Through reasonable selection and operation, it can significantly improve the quality and efficiency of repair and extend the service life of the equipment.

Core functions and features of the equipment:

High-pressure spraying system

Pressure range: 10-50 bar (adjusted according to the repair thickness and material properties).

Nozzle design: replaceable nozzle, suitable for refractory materials of different particle sizes (such as less than 3mm).

Material conveying and mixing system

Automatic mixing ratio control of dry powder and water (such as lime refractory and water are mixed in a ratio of 1:0.3-0.5).

Screw conveyor or pneumatic conveying system to ensure continuous and stable supply of materials.

Temperature and humidity control

Equipped with heating device (such as electric heating or steam heating) to prevent the material from condensing in low temperature environment.

Humidity sensor monitoring to ensure the stability of the moisture content of the gunning material (such as the moisture content of lime material is controlled at 10%-15%).

Automation control system

PLC control to achieve real-time adjustment of parameters such as injection volume, pressure, speed, etc.

Remote operation function to reduce the risk of manual operation.