This automatic lightweight concrete equipment is equipped with daily production report output interface or printing device as standard, which can summarize and output or print the daily consumption of cement, fly ash, foaming agent and other materials as well as the output of lightweight concrete.

Full-automatic control, equipped with lightweight concrete density monitoring and control device, the equipment can automatically adjust the ratio of materials at the front end according to the density data detected, so that the density of the lightweight concrete produced meets the set requirements.

2. Standard with material batching and measuring device, cement, powder, water, etc. can be measured separately, accurate control of material ratios.

3. Fully automatic lightweight concrete equipment is equipped with lightweight concrete density monitoring and control device, adopting touch screen intelligent control system, the working status of the equipment and various parameters are intuitively displayed on the screen, which is convenient for the judgment of the working status and centralized control.

4. Powder metering, slurry mixing, and slurry storage are divided into a three-tier structure, which can be added or subtracted in combination as needed.

5. Optional lightweight concrete density monitoring and control device developed by our company has reached the domestic leading level, which can instantly detect the wet density and dry density of lightweight concrete produced by the equipment and provide reliable data for the engineering quality inspection department.

|

Item |

LF30A Automatic lightweight concrete plant |

Remark |

|||

|

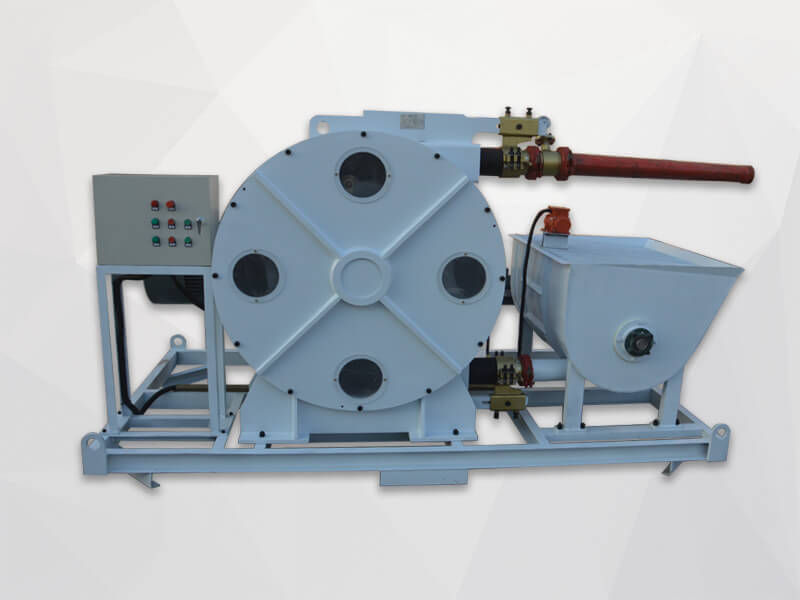

Pumping and foaming systems |

Capacity(m3/h) |

25~30 |

Density 450kg/m3 |

||

|

Conveying distance(m) |

Horizontal |

1200 |

|

||

|

Vertical |

160 |

|

|||

|

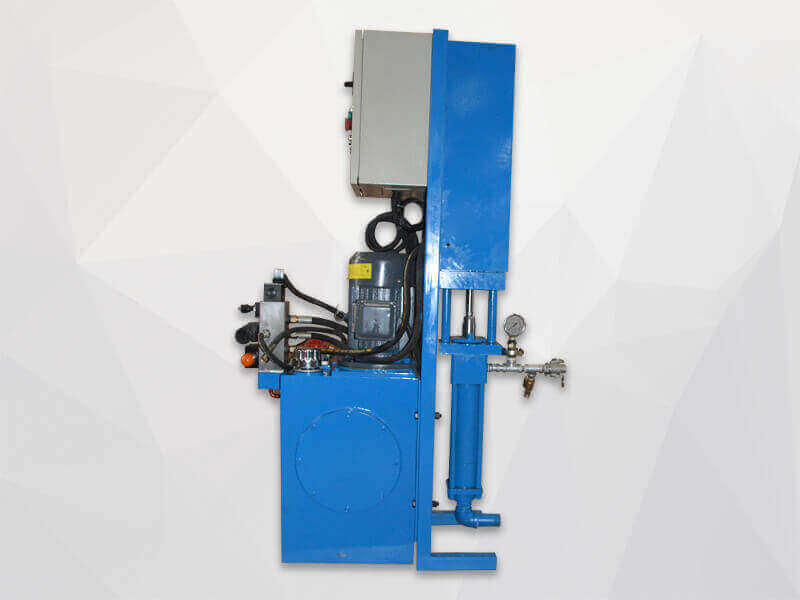

Motor power(kw) |

Pump motor |

22 |

|

||

|

Foaming motor |

7.5 |

|

|||

|

Concrete cylinder diameter(mm) |

Φ120 |

|

|||

|

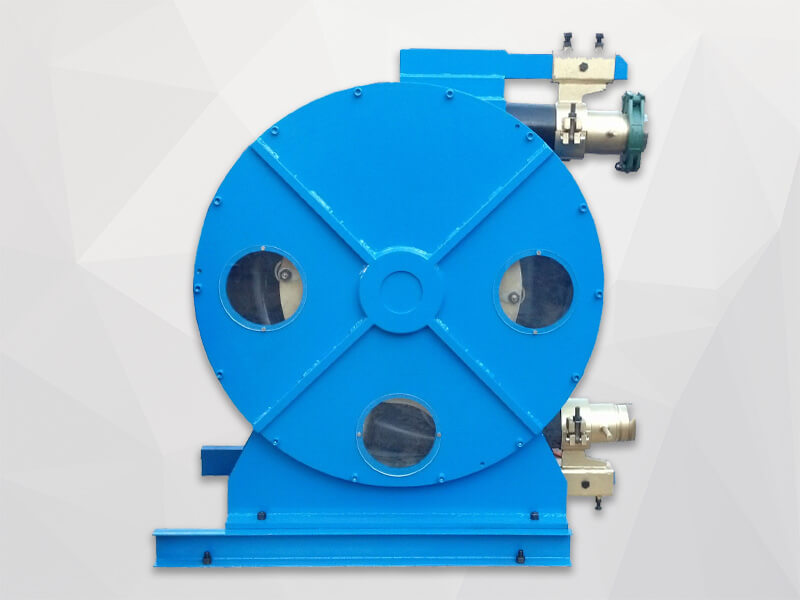

Pumping form |

Ball valve double cylinder hydraulic push |

|

|||

|

Density range(kg/m3) |

350-800 |

|

|||

|

Foam multiplication rate |

Adjustable |

|

|||

|

Wet density testing |

Precision<5% |

Optional accessories |

|||

|

Dry density testing |

Precision<5% |

Optional accessories |

|||

|

Flow testing |

Cement slurry flow detection display |

Precision<2% |

Optional accessories |

||

|

Lightweight concrete flow detection display |

Precision<2% |

Optional accessories |

|||

|

Foaming agent flow detection display |

Precision<2% |

Optional accessories |

|||

|

Pipe diameter(mm) |

Φ50 |

|

|||

|

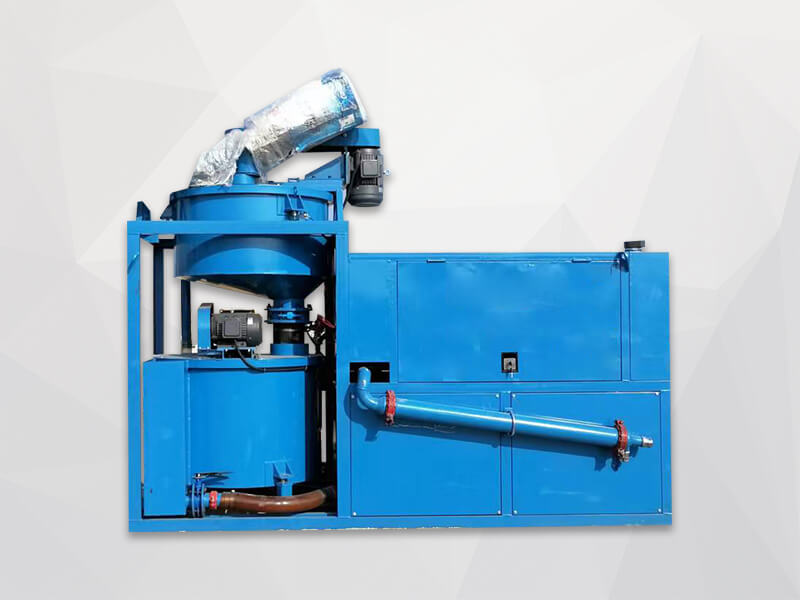

Mixing system |

Mixer tank volume(L) |

500 |

|

||

|

Storage mixer volume (L) |

760 |

|

|||

|

Motor power (kw) |

Mixer |

4 |

|

||

|

Storage mixer |

4 |

|

|||

|

Water pump |

0.75 |

|

|||

|

Screw conveyor |

7.5 |

|

|||

|

Screw conveyor |

Φ165x6m |

|

|||

|

Auto-weighing system |

Cumulative measurement |

Optional |

|||

|

Control system |

Control method |

PLC control, touch screen display and input |

Optional |

||

|

Parameter printing |

Lightweight concrete proportions printable |

Optional |

|||

|

Lightweight concrete productivity printable |

Optional |

||||

|

Overall dimension |

Mainframe(Length x Width x Height mm) |

3350x1540x2672 |

|

||

|

Weight(kg) |

2500 |

|

|||

Configuration of major components:

|

Model |

LF30A Automatic lightweight concrete station |

|

Main oil pump |

Hefeiwanye |

|

Motor |

Shandonghuali/Qingdaohongqi |

|

valve assembly |

Taiwan North Precision Machinery |

|

Pressure gauge |

Seismic pressure gauge made in Wuxi |

|

Hydraulic hose |

Manuli, Italy |

|

Seal |

American Parker |

|

PLC unit |

OMRON Japan |

|

Relay |

OMRON Japan |

|

proximity switch |

Schneider France |

|

Remote controls |

wireless remote |

|

Button |

Schneider France |

Configuration list (including Φ50 delivery hose 100m):

|

No. |

Name |

Spec. |

Unit |

Qty. |

|

1 |

High pressure conveying hose |

Φ50-20m/pc |

pcs |

5 |

|

2 |

High pressure hose rings |

Φ50 |

pcs |

5 |

|

3 |

Three-phase submersible pump |

QX7-18-0.75 |

set |

1 |

|

4 |

Water packages |

3m3 |

pc |

1 |

|

5 |

Water pack holder |

|

set |

1 |

|

6 |

Conveying piston |

BS25C.1-13(Φ120) |

pcs |

2 |

|

7 |

O-ring |

LF30A |

set |

1 |

|

8 |

Proximity switch |

ZLJ-A18-8ANA-Q |

pc |

1 |

|

9 |

Water pump accessories |

|

set |

1 |

|

10 |

Canvas sleeve |

Φ165 |

pc |

1 |

|

11 |

Rubber cylinder |

170x12x380 |

pc |

1 |

|

12 |

Hose clamps |

Φ165 |

pcs |

4 |

|

13 |

Remote control |

220V |

pc |

1 |

|

14 |

Toolbox |

LF30A |

pc |

1 |

|

15 |

Instruction manual |

LF30A |

pc |

1 |

-

LFC1000-H foam concrete machine is composed of mixer, agitator, foam generator, hose pump, equipped with screw feeder, belt conveyor and submersible pump. The equipment is equipped with a weighing sensor and automatic batching system, which can set each batching weight and realize automatic feeding and full mixing. The process is completely controlled by the auto-weighing system. After the preparation work is completed, press the automatic button to start the automatic working. The mixer is started to mixing. Sand, cement, water and foaming agent are loaded in turn and mixed quickly after reaching the set weight. After the mixing is even, open the discharge door. The mixture flow down into the lower screen of the agitator. The low speed mixing blades are equipped in this agitator. After the mixture completely flow down, close the door and continue the next batch mixing. At the same time, start the hose pump to pump the foam concrete mixture to the work site.LFC1000-H Foam concrete machine supplier

LFC1000-H foam concrete machine is composed of mixer, agitator, foam generator, hose pump, equipped with screw feeder, belt conveyor and submersible pump. The equipment is equipped with a weighing sensor and automatic batching system, which can set each batching weight and realize automatic feeding and full mixing. The process is completely controlled by the auto-weighing system. After the preparation work is completed, press the automatic button to start the automatic working. The mixer is started to mixing. Sand, cement, water and foaming agent are loaded in turn and mixed quickly after reaching the set weight. After the mixing is even, open the discharge door. The mixture flow down into the lower screen of the agitator. The low speed mixing blades are equipped in this agitator. After the mixture completely flow down, close the door and continue the next batch mixing. At the same time, start the hose pump to pump the foam concrete mixture to the work site.LFC1000-H Foam concrete machine supplier -

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine for Sale

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine for Sale -

LM2000 concrete foaming machine is one of the high capacity foam concrete mixers. It includes feeding systems, pumping systems, foaming systems and mixing systems. All procedures are program controlled and very labor efficient. The amount of feed, water and foam can be accurately weighed to ensure the quality of the final foamed concrete.LM2000 Concrete Foaming Machine

LM2000 concrete foaming machine is one of the high capacity foam concrete mixers. It includes feeding systems, pumping systems, foaming systems and mixing systems. All procedures are program controlled and very labor efficient. The amount of feed, water and foam can be accurately weighed to ensure the quality of the final foamed concrete.LM2000 Concrete Foaming Machine -

LGP10-40E grout pump for high rise building is a custom made mini type grouting pump, mainly used for injecting cement grout tubes, repairing damaged / dangerous structures, consolidating or weatherproofing walls, rocks, dams, and tunnels, pumping special products for anchoring and seals. It can also be used for teaching and research.LGP10-40-E grout pump equipment for high rise building

LGP10-40E grout pump for high rise building is a custom made mini type grouting pump, mainly used for injecting cement grout tubes, repairing damaged / dangerous structures, consolidating or weatherproofing walls, rocks, dams, and tunnels, pumping special products for anchoring and seals. It can also be used for teaching and research.LGP10-40-E grout pump equipment for high rise building

.jpg)

.jpg)