Your position:

Home > Products > Foam Concrete Machine

LF100 Foam concrete mixing station for coal mining highway backfilling project

LF100 Foam Concrete Mixing Station is an ideal choice for coal mining highway backfilling projects, offering efficiency, portability, cost-effectiveness, stability, intelligent control, and reliable after-sales service.

LF100

70-100

60-70

35

1000

110

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LF100 Foam concrete mixing station can meet all the large-scale projects such as road surface filling and abutment back filling for the quality of foam concrete. Foam concrete, also called Cellular Lightweight Concrete, has been used in over 40 countries for building houses, apartments, schools, hospitals, industrial buildings, etc.

Benefits of foam concrete:

1. Lightweight: Dry density 400 kg/m^3 -1600kg/m^3 , 1/8-1/2 as light as common concrete;

2. High Compression Strength: Compression strength is ranging from 0.6 MPa to 25 MPa, 4 times as traditional aerated concrete;

3. Thermal Insulation: Good heat preservation and good thermal insulation;

4. Impermeability: Low water-intake rate and high impermeability;

5. Saving cost: Easy and fast production. No primary energy and reduced transportation costs.

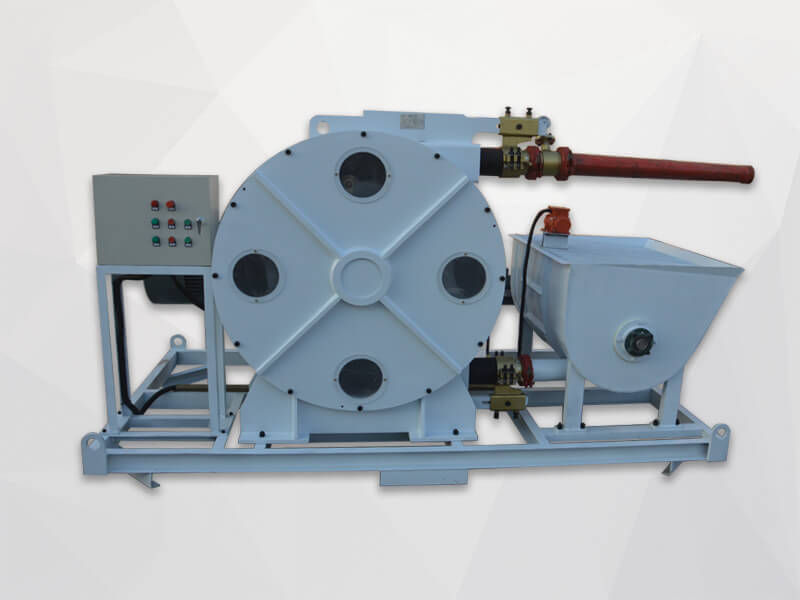

LF100 Foam concrete mixing station includes screw conveyor, concrete mixer, foam generator and foam concrete pump, adopts advanced automatic PLC intelligent control system, high-definition intelligent touch screen operation, which can realize precise control of product bulk density, automatic weighing of slurry, instantaneous and cumulative flow display, etc. It is the most automated foam concrete production equipment.

LF100 Foam concrete mixing station operates based on the following working principle:

1. The LF100 Foam Concrete Mixing Station combines cement, sand, and other raw materials in the concrete mixer, creating a slurry.

2. A foam generator is utilized to mechanically produce foam using a foam agent. The foam generated is abundant, fine, and possesses independent and homogeneous properties.

3. The slurry and foam are then thoroughly mixed, ensuring a uniform distribution of the foam within the mixture.

4. Subsequently, the foam concrete is pumped out from the pumping system to the designated work site or mold.

5. Following natural curing, the foam concrete solidifies and takes shape.

Benefits of foam concrete:

1. Lightweight: Dry density 400 kg/m^3 -1600kg/m^3 , 1/8-1/2 as light as common concrete;

2. High Compression Strength: Compression strength is ranging from 0.6 MPa to 25 MPa, 4 times as traditional aerated concrete;

3. Thermal Insulation: Good heat preservation and good thermal insulation;

4. Impermeability: Low water-intake rate and high impermeability;

5. Saving cost: Easy and fast production. No primary energy and reduced transportation costs.

LF100 Foam concrete mixing station includes screw conveyor, concrete mixer, foam generator and foam concrete pump, adopts advanced automatic PLC intelligent control system, high-definition intelligent touch screen operation, which can realize precise control of product bulk density, automatic weighing of slurry, instantaneous and cumulative flow display, etc. It is the most automated foam concrete production equipment.

LF100 Foam concrete mixing station operates based on the following working principle:

1. The LF100 Foam Concrete Mixing Station combines cement, sand, and other raw materials in the concrete mixer, creating a slurry.

2. A foam generator is utilized to mechanically produce foam using a foam agent. The foam generated is abundant, fine, and possesses independent and homogeneous properties.

3. The slurry and foam are then thoroughly mixed, ensuring a uniform distribution of the foam within the mixture.

4. Subsequently, the foam concrete is pumped out from the pumping system to the designated work site or mold.

5. Following natural curing, the foam concrete solidifies and takes shape.

Application

LF100 Foam concrete mixing station is utilized in various applications based on its working principle:

4. Upstanding beam foundation ditches filling: It is utilized for filling upstanding beam foundation ditches, providing stability and support to structures.

5. Sound insulation and fire protection walls: Foam concrete produced by the LF100 Foam Concrete Mixing Station is used to construct walls that offer sound insulation and fire protection properties.

6. Playground and track construction: The LF100 Foam Concrete Mixing Station is employed in the construction of playgrounds and tracks, providing a lightweight and durable surface.

7. Sound insulation layer, tunnel lining filling: It is utilized for filling sound insulation layers and lining tunnels, enhancing soundproofing and structural integrity.

8. Cellar, basement, and arch filling: The LF100 Foam Concrete Mixing Station is used to fill cellars, basements, and arches, providing structural support and insulation.

9. Sewers and drains filling: Foam concrete produced by the LF100 Foam Concrete Mixing Station is employed for filling sewers and drains, ensuring proper drainage and stability.

10. Horizontal floor heightening: It is used to increase the height of horizontal floors, enabling modifications and renovations.

11. Water tank and fuel tank building: The LF100 Foam Concrete Mixing Station is employed in the construction of water tanks and fuel tanks, providing insulation and structural strength.

12. Platform filling and mending: It is utilized for filling and repairing platforms, ensuring stability and durability.

13. Garden and rockeries: Foam concrete produced by the LF100 Foam Concrete Mixing Station is used in the construction of gardens and rockeries, providing a lightweight and customizable solution.

14. Foam concrete block: The LF100 Foam Concrete Mixing Station is utilized for producing foam concrete blocks, which are used in various construction applications.

15. Foamed concrete precast, hollow wallboard casting: It is employed for casting foamed concrete precast elements and hollow wallboards, offering versatility and efficiency in construction projects.

1. External wall thermal insulation: The LF100 Foam Concrete Mixing Station is employed for insulating the external walls of buildings, enhancing their thermal performance.

2. Thermal insulation roofing: It is used to create thermal insulation layers for roofs, improving energy efficiency and temperature regulation.

3. Thermal flooring: The LF100 Foam Concrete Mixing Station enables the production of foam concrete for thermal insulation in flooring systems.

3. Thermal flooring: The LF100 Foam Concrete Mixing Station enables the production of foam concrete for thermal insulation in flooring systems.

4. Upstanding beam foundation ditches filling: It is utilized for filling upstanding beam foundation ditches, providing stability and support to structures.

5. Sound insulation and fire protection walls: Foam concrete produced by the LF100 Foam Concrete Mixing Station is used to construct walls that offer sound insulation and fire protection properties.

6. Playground and track construction: The LF100 Foam Concrete Mixing Station is employed in the construction of playgrounds and tracks, providing a lightweight and durable surface.

7. Sound insulation layer, tunnel lining filling: It is utilized for filling sound insulation layers and lining tunnels, enhancing soundproofing and structural integrity.

8. Cellar, basement, and arch filling: The LF100 Foam Concrete Mixing Station is used to fill cellars, basements, and arches, providing structural support and insulation.

9. Sewers and drains filling: Foam concrete produced by the LF100 Foam Concrete Mixing Station is employed for filling sewers and drains, ensuring proper drainage and stability.

10. Horizontal floor heightening: It is used to increase the height of horizontal floors, enabling modifications and renovations.

11. Water tank and fuel tank building: The LF100 Foam Concrete Mixing Station is employed in the construction of water tanks and fuel tanks, providing insulation and structural strength.

12. Platform filling and mending: It is utilized for filling and repairing platforms, ensuring stability and durability.

13. Garden and rockeries: Foam concrete produced by the LF100 Foam Concrete Mixing Station is used in the construction of gardens and rockeries, providing a lightweight and customizable solution.

14. Foam concrete block: The LF100 Foam Concrete Mixing Station is utilized for producing foam concrete blocks, which are used in various construction applications.

15. Foamed concrete precast, hollow wallboard casting: It is employed for casting foamed concrete precast elements and hollow wallboards, offering versatility and efficiency in construction projects.

Features

1. Beautiful: The shape is made of high-strength precision thickened steel plate, professional cover parts and sheet metal parts are manufactured and produced, and the appearance is beautiful.

2. Convenience: The whole container design is adopted, and the structure is compact, which is convenient for transportation, lifting and construction.

3. High efficiency: the production capacity is as high as 70-100 cubic meters / hour.

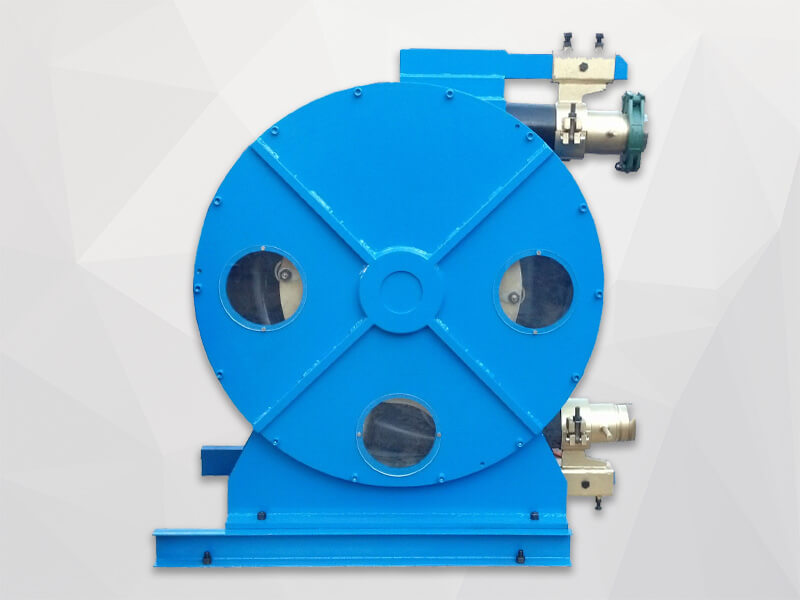

4. Economy: Adopting the most advanced hose pumping system, the operation is simple, the failure rate is low, the maintenance is convenient and the cost is low.

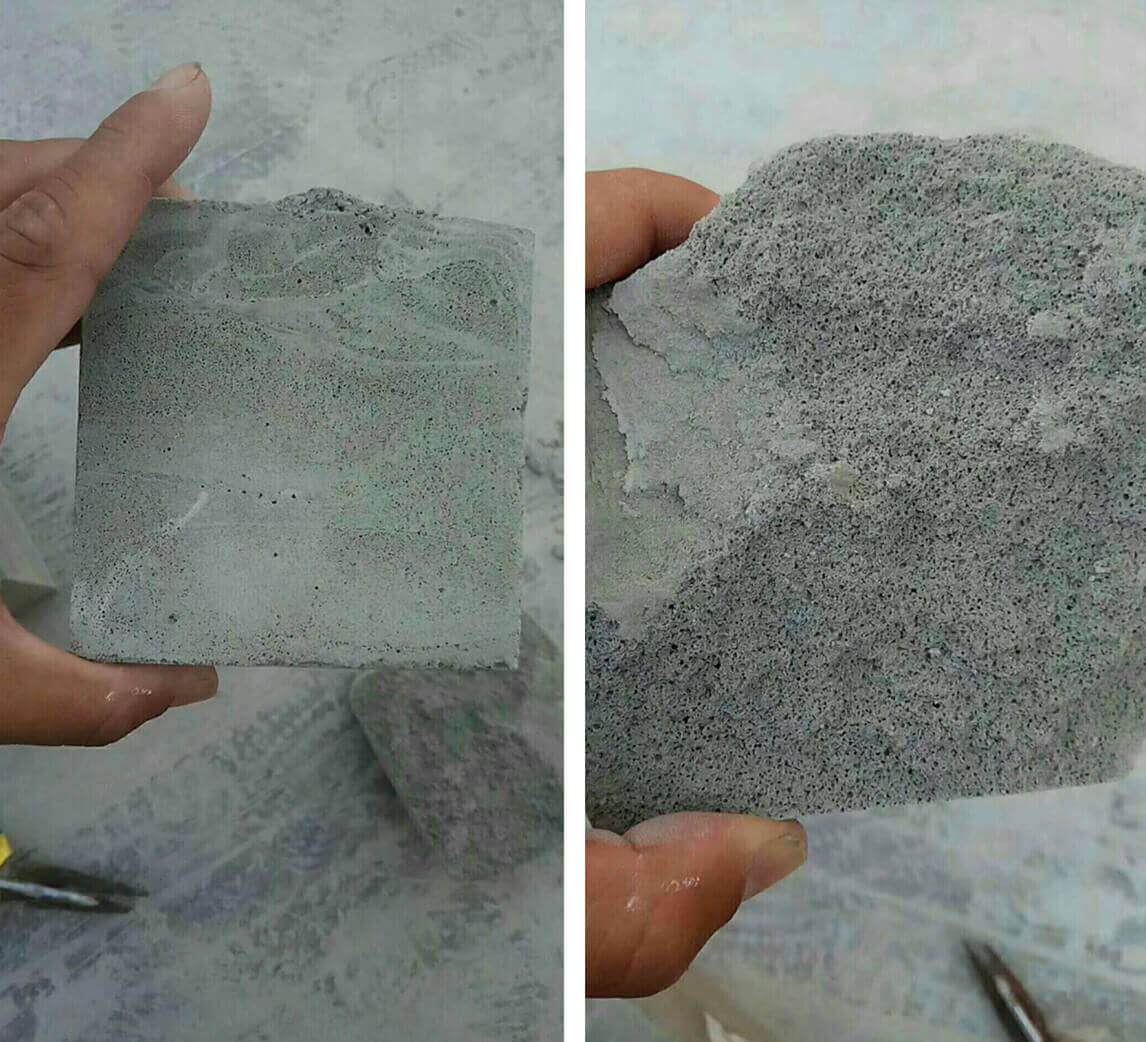

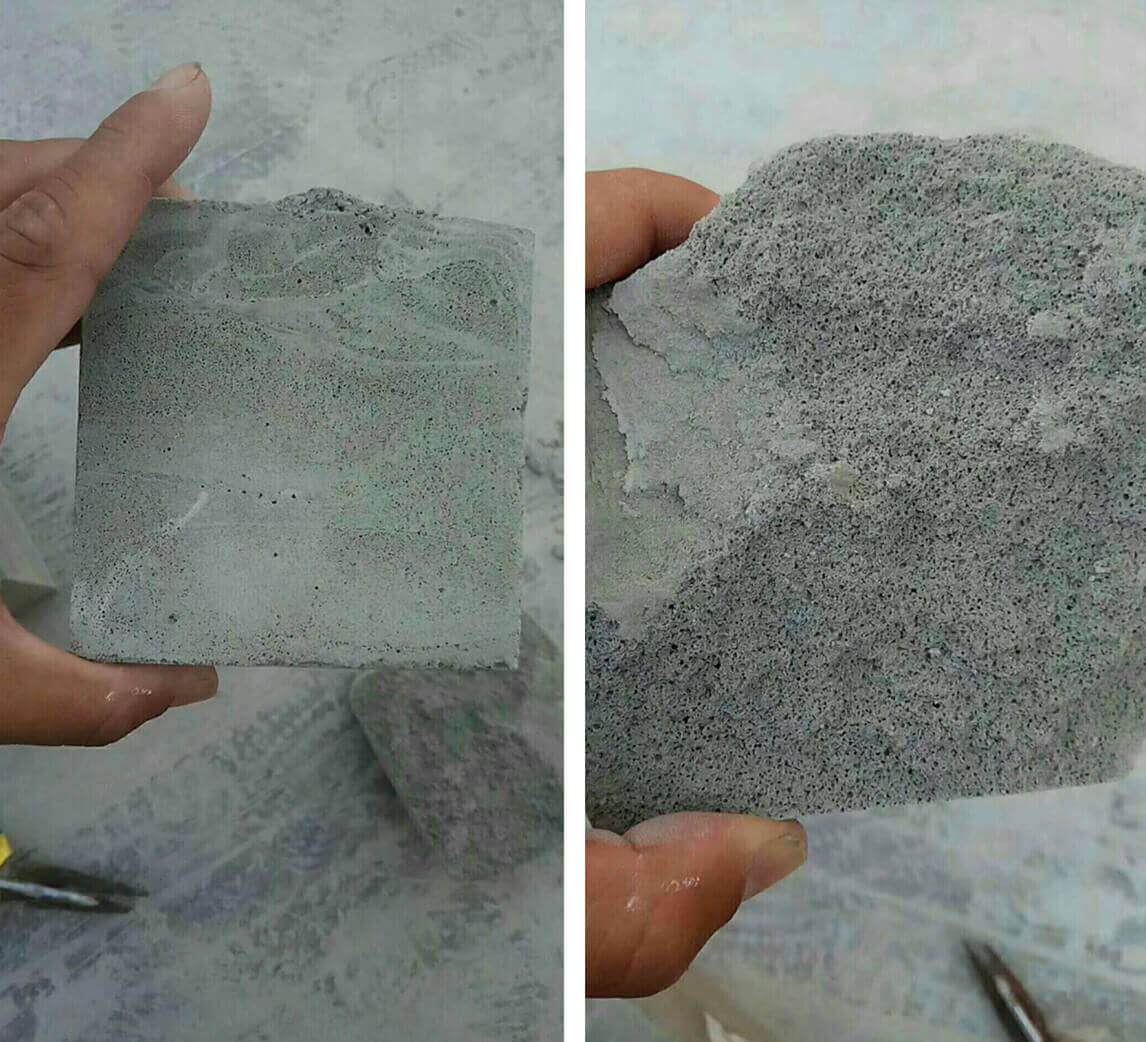

5. Stable: The output of the slurry is even and stable, and the density of the finished foam concrete is uniform and the quality is stable.

6. Intelligent: Adopt automatic PLC intelligent control system, high-definition intelligent touch screen operation. The cement and water are fully and accurately weighed to achieve precise control of the water-cement ratio, thus controlling the bulk density of the foam concrete.

7. Service: professional technical team and perfect after-sales service system, provide professional technical guidance and technical support 24 hours a day, so that you can buy worry-free.

2. Convenience: The whole container design is adopted, and the structure is compact, which is convenient for transportation, lifting and construction.

3. High efficiency: the production capacity is as high as 70-100 cubic meters / hour.

4. Economy: Adopting the most advanced hose pumping system, the operation is simple, the failure rate is low, the maintenance is convenient and the cost is low.

5. Stable: The output of the slurry is even and stable, and the density of the finished foam concrete is uniform and the quality is stable.

6. Intelligent: Adopt automatic PLC intelligent control system, high-definition intelligent touch screen operation. The cement and water are fully and accurately weighed to achieve precise control of the water-cement ratio, thus controlling the bulk density of the foam concrete.

7. Service: professional technical team and perfect after-sales service system, provide professional technical guidance and technical support 24 hours a day, so that you can buy worry-free.

Product Details

Technical Parameters

Technical Data

| Model | LF100 Foam concrete mixing station | |

| The actual output (m³/h) | 70-100 | |

| Foam capacity(m³/h) | 60-70 | |

| Foam concrete pump capacity(m³/h) | 35 | |

| Max. pumping distance(m) | Horizontal | 1000 |

| Vertical | 110 | |

| Voltage | 3 phase, 380V, 50Hz | |

| Total motor power(kw) | 54 | |

| Total weight (kg) | 6000 | |

| Over dimension(mm) | 4000×1810×2450 | |

| No. | Name | Spec. | Unit | Qty. | Remarks |

| 1 | Foam concrete machine | GF100 | set | 1 | |

| 2 | Conveyor | Φ273×6000 | set | 1 | |

| 3 | Delivery hoses | Φ76 | pc | 5 | 20m/pc |

| 4 | Water tank with holder | set | 1 | |

|

| 5 | Steel tube | Φ76 | pc | 1 | 6m |

| 6 | Steel tube | Φ25 | pc | 2 | 6m |

| 7 | Suction tube | pc | 1 | ||

| 8 | Water pump | 380V-5.5Kw | set | 1 | |

| 9 | Waterproof poncho | pc | 1 | ||

| 10 | Work clothes | set | 2 | ||

| 11 | Dust bag | pc | 2 | (Φ280×500)(Φ400×500) 个 |

|

| 12 | Tool box | 1 set | |||

| 13 | Documents | Manual, packing list and warranty card. | |||

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

Lead Equipment Co., Ltd. is a manufacturing, technical service and trading company in CLC lightweight concrete field. We have worked in this field nearly 20 years, our automatic foam cement concrete equipment mainly used for CLC blocks, wall cast in-situ, roof insulation etc. project.LF60A Large scale automatic foam cement concrete back filling machine equipment

Lead Equipment Co., Ltd. is a manufacturing, technical service and trading company in CLC lightweight concrete field. We have worked in this field nearly 20 years, our automatic foam cement concrete equipment mainly used for CLC blocks, wall cast in-situ, roof insulation etc. project.LF60A Large scale automatic foam cement concrete back filling machine equipment -

LF40A Foam concrete lightweight concrete work stations are commonly used in various construction applications, including residential and commercial building construction, insulation layers, void filling, and lightweight concrete block production.LF40A Foam concrete lightweight concrete work station

LF40A Foam concrete lightweight concrete work stations are commonly used in various construction applications, including residential and commercial building construction, insulation layers, void filling, and lightweight concrete block production.LF40A Foam concrete lightweight concrete work station -

.jpg)

.jpg)