Your position:

Home > Products > Refractory Gunning Machine

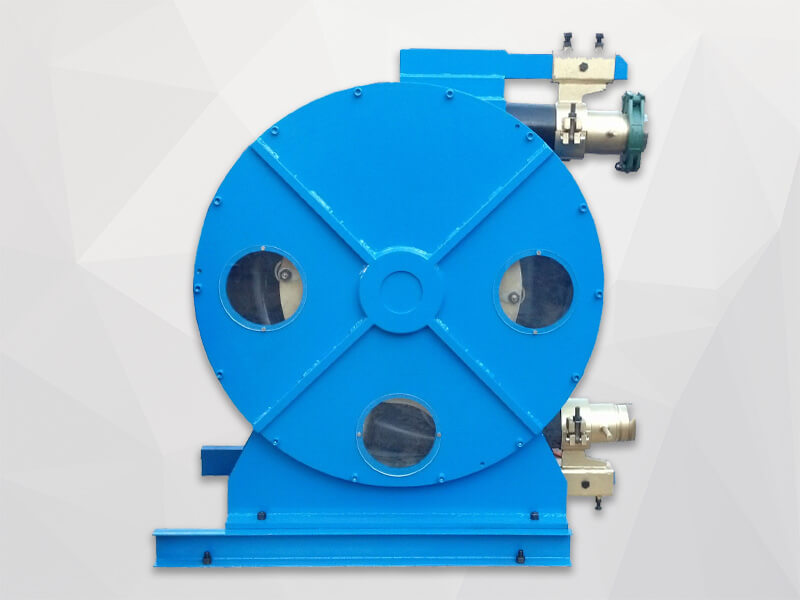

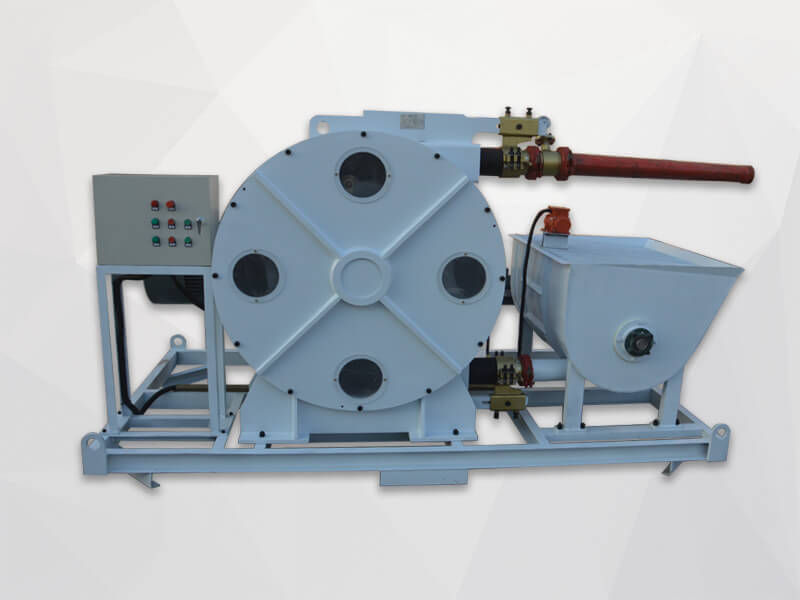

LZ-9ER Refractory gunning machine for hot repair of ladles and melting furnaces

LZ-9ER Refractory gunning machine for hot repair of ladles and melting furnaces can be used for the hot repair of ladles and melting furnaces as well as relining or cold repair of the back lining in cement and steel plant.

3-9m3 /h(6-18ton/h)

100m

Φ20 mm

64mm

0.2-0.4MPa

10~12m3/min

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

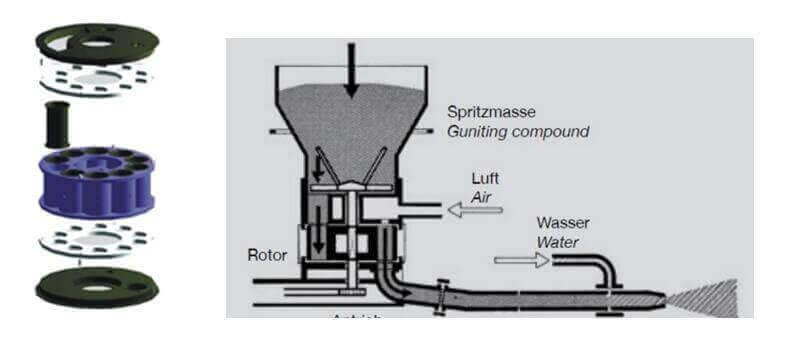

LZ-9ER Refractory gunning machine for hot repair of ladles and melting furnaces is specially designed for spraying refractory in steel plant and cement plant. It is equipped with ABB frequency converter, high pressure water pump, new type pre-dampening nozzle assy, etc. With this LZ-9ER Refractory gunning machine for hot repair of ladles and melting furnaces, you can get low dust and high performance spraying flow in nozzle.

The LZ-9ER Refractory gunning machine is capable of spraying various water-soluble materials, including putty powder, paint, latex paint, real stone paint, cement mortar, dry powder mortar, thermal insulation mortar, waterproof material, fireproof material, heat insulation material, sound absorption material, and more.

The LZ-9ER Refractory gunning machine is capable of spraying various water-soluble materials, including putty powder, paint, latex paint, real stone paint, cement mortar, dry powder mortar, thermal insulation mortar, waterproof material, fireproof material, heat insulation material, sound absorption material, and more.

Application

The LZ-9ER refractory gunning machine is designed for the hot repair of ladles and melting furnaces. It's a specialized equipment used to spray refractory materials, such as castables and gunning mixes, onto the inner surfaces of ladles and furnaces to repair or line them with heat-resistant materials. This process helps maintain the integrity and efficiency of these high-temperature industrial vessels.

Test of LZ-9ER refractory gunning machin working effect:

Test of LZ-9ER refractory gunning machin working effect:

Features

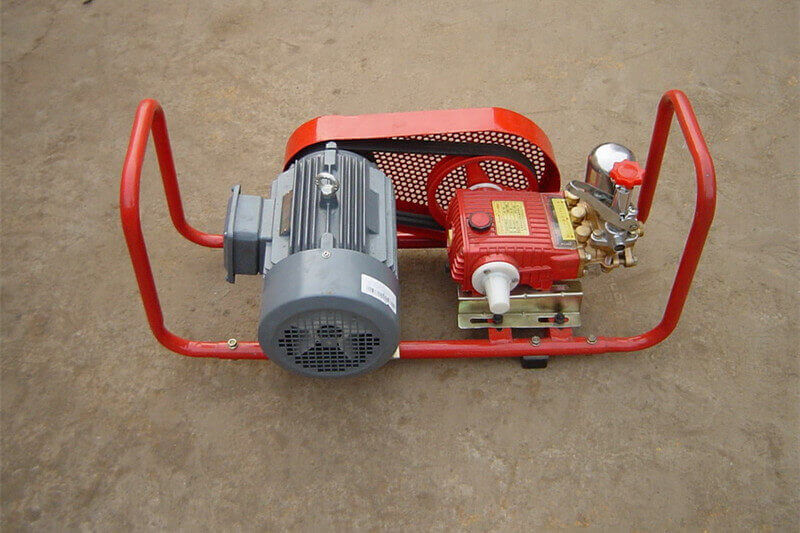

1. High pressure water pump, 30 bar pressure make sure to add water fully atomize, and mix evenly.

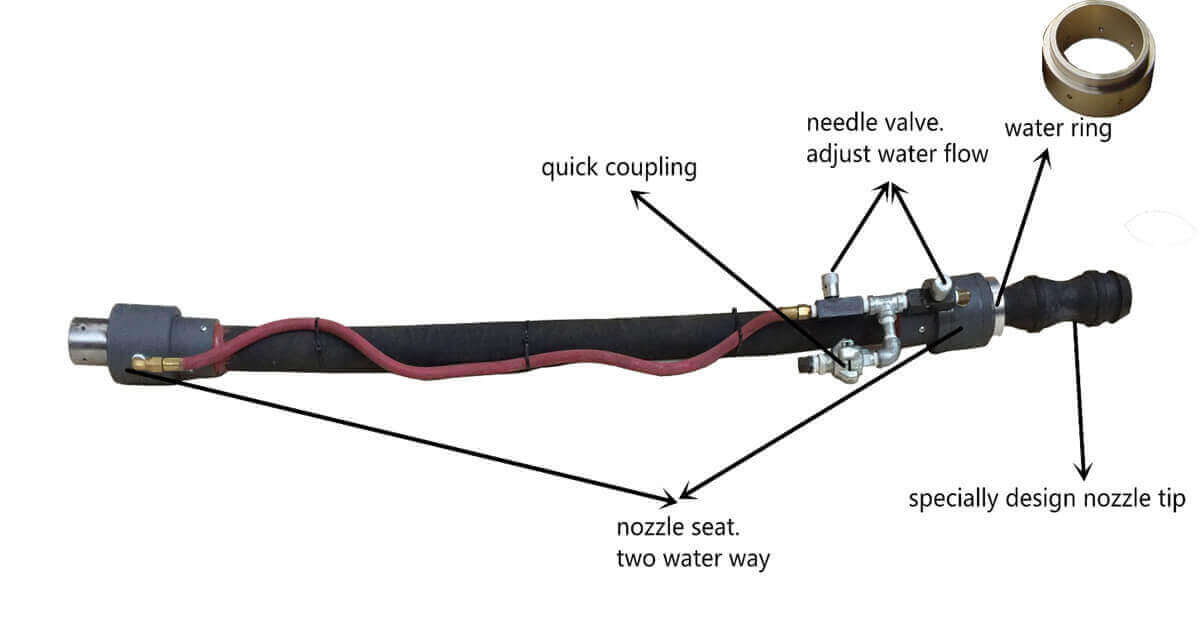

2. Lightweight nozzle

1. Low rebound, low dust.

2. Reduce the additive water amount.

3. Improve refractory compactness and strength.

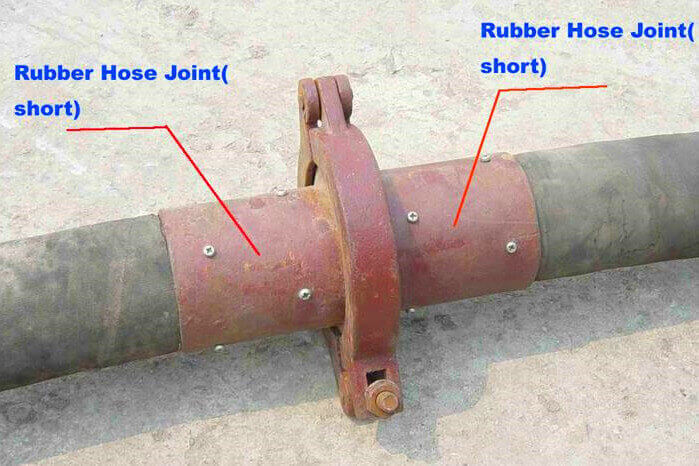

3. Coupling and clamp

The coupling and clamp are optional as below:

The coupling and clamp are optional as below:

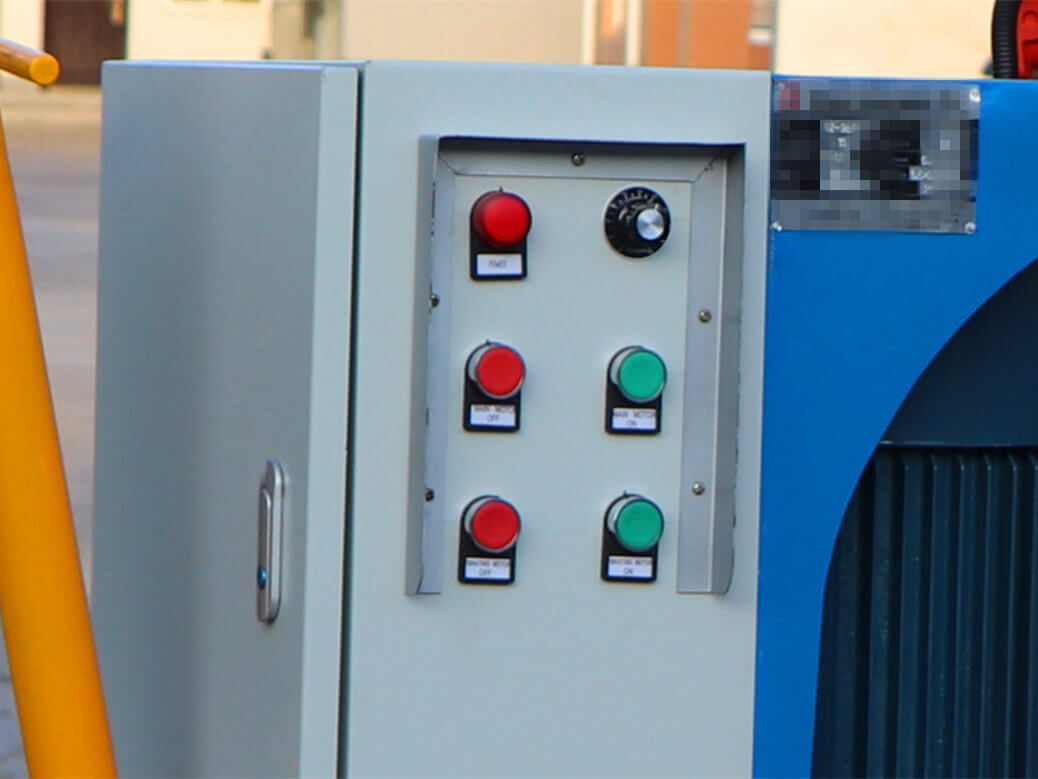

4. Variable output with variable-frequency drive

5. Electric vibrator

6. Heavy-duty solid wheels

7. Clean dust gun

8. Protect frame

9. Collect dust bag

10. Bag cutter and hopper with vibrator

11. Blast rubber hose

12. Spare parts

Product Details

Technical Parameters

Technical Data

| LZ-9ER Refractory gunning machine specification (with electric motor drive): | |

| Rated Output | 3-9m3 /h(6-18ton/h) |

| Max. Horizontal Conveying Distance | 100m |

| Max. Aggregate Size | Φ20 mm |

| Conveying Hose Inner Diameter | 64mm |

| Operating Air Pressure | 0.2-0.4MPa |

| Air Consumption | 10~12m3/min |

| Motor Power | 7.5kW |

| Voltage | 3 phase,380V,50Hz |

| Material Charging Height | 1.2m |

| Rotor Speed | 0-11r/min |

| Overall Dimension(L×W×H) | 1.65×0.9×1.3m |

| Weight | 900kg |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LZ-6AR/RD Pneumatic motor refractory gunning machine is a small, economical, versatile, simple, and safe refractory gunning machine for refractory installation in steel plants, cement factories, furnaces, etc.LZ-6AR/RD Pneumatic motor refractory gunning machine

LZ-6AR/RD Pneumatic motor refractory gunning machine is a small, economical, versatile, simple, and safe refractory gunning machine for refractory installation in steel plants, cement factories, furnaces, etc.LZ-6AR/RD Pneumatic motor refractory gunning machine -

LZ-1.5ER refractory gunning machine for furnace kiln can be used for spray refractory materials for refractory gunite jobsite such as lining kilns, boilers, furnaces.LZ-1.5ER Refractory gunning machine for furnace kiln

LZ-1.5ER refractory gunning machine for furnace kiln can be used for spray refractory materials for refractory gunite jobsite such as lining kilns, boilers, furnaces.LZ-1.5ER Refractory gunning machine for furnace kiln -

Refractory gunning machine is a stereotyped product with good quality and durability. The wearing parts, rotating plate, bonding plate, spray gun and other accessories are adequately stocked.LZ-3ER/S Refractory gunning machine

Refractory gunning machine is a stereotyped product with good quality and durability. The wearing parts, rotating plate, bonding plate, spray gun and other accessories are adequately stocked.LZ-3ER/S Refractory gunning machine -

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine

.jpg)

.jpg)

.jpg)