Your position:

Home > Products > Refractory Pan Mixer

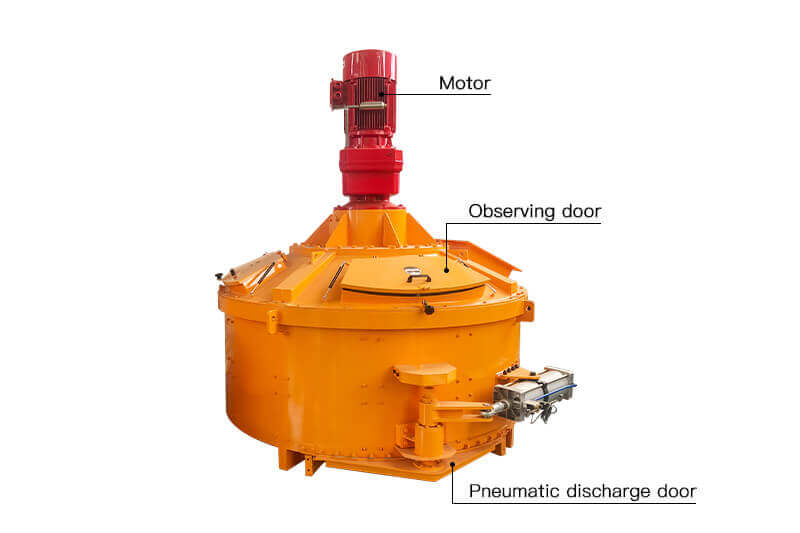

LCPM Hydraulic / pneumatic discharge planetary concrete mixer

LCPM Hydraulic / pneumatic discharge planetary concrete mixer is not only for mixing concrete, it also can be applied to glass ceramics, refractories, and other industries.

LCPM750

1125

1800

750

30

1*3

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

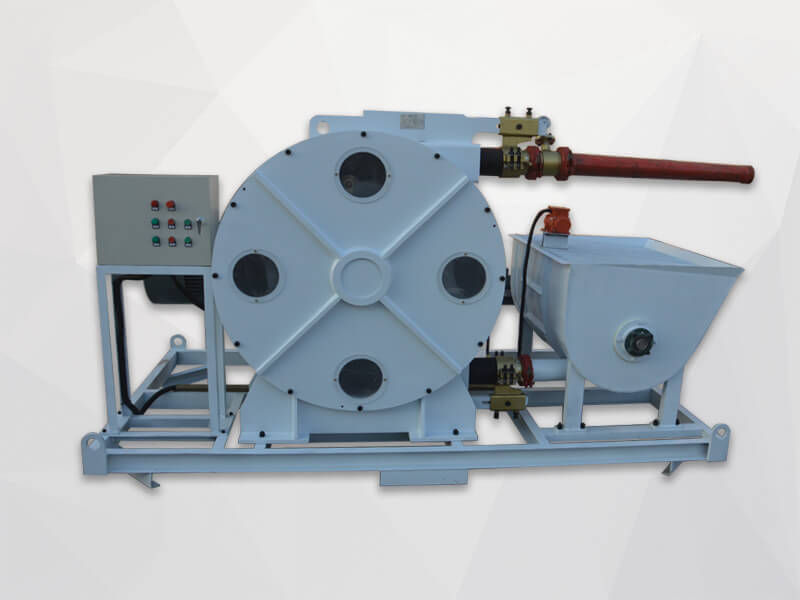

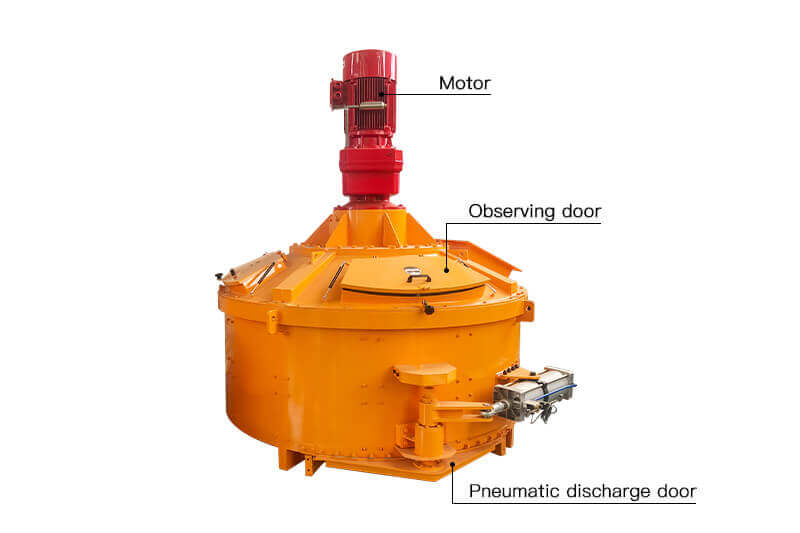

LCPM Hydraulic / pneumatic discharge planetary concrete mixer adopts a new convection star mixing concept, which can achieve high homogeneity of materials in the shortest time. It is suitable for mixing various high-quality and high-performance concrete, and is widely used in glass , ceramics, refractory materials, fertilizers and other special industries.

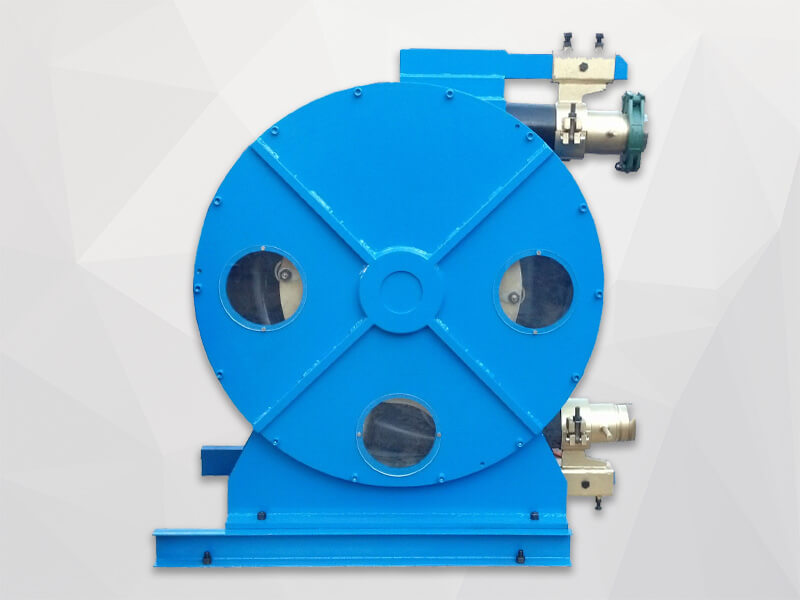

Counter-current gearing system (patent technology) of LCPM Hydraulic / pneumatic discharge planetary concrete mixer:

The rotation direction of the mixing device is opposite to the revolution direction of the entire mixing device. The directions of different mixing planets are also different. During the mixing process, the materials have both cyclic movement and convection movement. Materials moving in opposite directions convection and impact each other, so that the components are fully contacted and Combined, truly achieve microscopic uniform distribution.

Convection mixing device of LCPM Hydraulic / pneumatic discharge planetary concrete mixer:

1. High efficiency, low energy consumption.

2. When the material ratio is the same, the mixing time is 15-20% shorter than that of a traditional planetary mixer.

3. The no-load current and load current are both 15-20% lower than traditional planetary mixers.

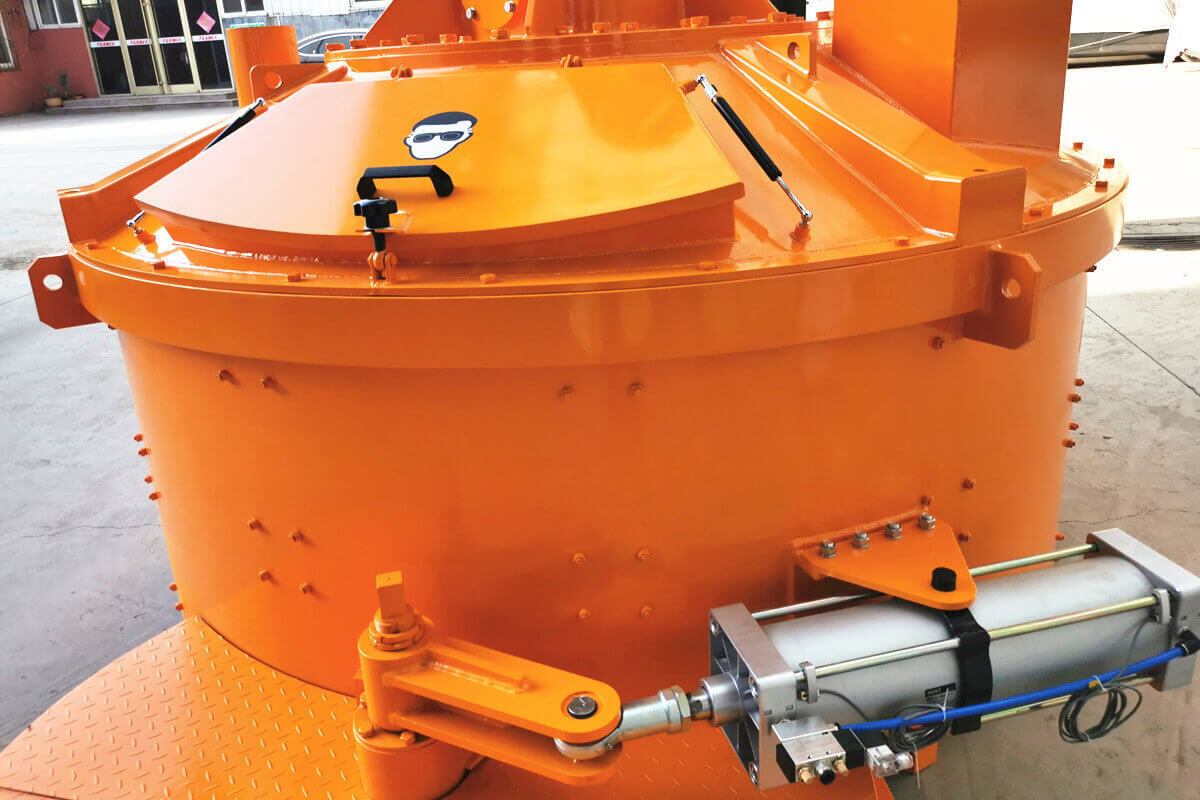

Comprehensive consideration of handling safety

The key-operated emergency stop in the junction box can stop the mixer immediately in case of emergency. Take off the key in maintenance to ensure the safety. The observing port on the maintenance gate can help to observe the mixing condition during mixer running. The high-reliable and high-sensitive safety switch equipped on the maintenance gate guarantees the motor can not be powered with the gate open.

Counter-current gearing system (patent technology) of LCPM Hydraulic / pneumatic discharge planetary concrete mixer:

The rotation direction of the mixing device is opposite to the revolution direction of the entire mixing device. The directions of different mixing planets are also different. During the mixing process, the materials have both cyclic movement and convection movement. Materials moving in opposite directions convection and impact each other, so that the components are fully contacted and Combined, truly achieve microscopic uniform distribution.

Convection mixing device of LCPM Hydraulic / pneumatic discharge planetary concrete mixer:

1. High efficiency, low energy consumption.

2. When the material ratio is the same, the mixing time is 15-20% shorter than that of a traditional planetary mixer.

3. The no-load current and load current are both 15-20% lower than traditional planetary mixers.

Comprehensive consideration of handling safety

The key-operated emergency stop in the junction box can stop the mixer immediately in case of emergency. Take off the key in maintenance to ensure the safety. The observing port on the maintenance gate can help to observe the mixing condition during mixer running. The high-reliable and high-sensitive safety switch equipped on the maintenance gate guarantees the motor can not be powered with the gate open.

Application

LCPM Hydraulic / pneumatic discharge planetary concrete mixer application case:

1. PC factory production line

The vertical shaft hydraulic / pneumatic discharge planetary concrete mixer used in the prefabricated PC special mixing station has various layouts, single outlet, double outlet, flexibility, reliability and high performance, and is suitable for a variety of fine mixing challenges.

2. Pipe pile factory concrete production line

Our company's pipe pile concrete production line can be divided into one-stage building type and two-stage station type structure according to the structural form. The scale and layout of the production line can be tailored according to the needs of the customer's site and production process.

3. UHPC ultra-high concrete production line

UHPC is an ultra-high-strength cement-based material with high strength, high toughness, and low porosity. It has ultra-high durability and mechanical properties, as well as excellent wear resistance and explosion resistance. It is especially suitable for long-span bridges and high-corrosion applications. environment of.

4. Brick production line mixing station

The supporting mixing system of the brick machine production line is a hydraulic/pneumatic discharge planetary concrete mixer, which has good performance, long service life, low failure rate, high uniformity of material mixing, fully automatic control system, and high metering progress.

5. Cement pipe and wire pole production line

The supporting mixing system of the cement pipe and wire pole production line is a vertical axis planetary concrete mixer machine. During the material mixing process, the mixing arm performs both revolution and rotation movements. The running trajectories overlap layer by layer, and there are no dead ends in the mixing, and there will be no low-speed mixing zone. Environmentally friendly feeding device and anti-fall-body lifting.

6. Refractory production line mixing station

Hydraulic / pneumatic discharge refractory planetary mixer has advanced working form, reliable mixing uniformity, stable operation and strong scalability. It has designed a variety of auxiliary devices to meet the needs of working conditions. Optional humidity, temperature, and consistency sensors are available with advanced equipment.

1. PC factory production line

The vertical shaft hydraulic / pneumatic discharge planetary concrete mixer used in the prefabricated PC special mixing station has various layouts, single outlet, double outlet, flexibility, reliability and high performance, and is suitable for a variety of fine mixing challenges.

2. Pipe pile factory concrete production line

Our company's pipe pile concrete production line can be divided into one-stage building type and two-stage station type structure according to the structural form. The scale and layout of the production line can be tailored according to the needs of the customer's site and production process.

3. UHPC ultra-high concrete production line

UHPC is an ultra-high-strength cement-based material with high strength, high toughness, and low porosity. It has ultra-high durability and mechanical properties, as well as excellent wear resistance and explosion resistance. It is especially suitable for long-span bridges and high-corrosion applications. environment of.

4. Brick production line mixing station

The supporting mixing system of the brick machine production line is a hydraulic/pneumatic discharge planetary concrete mixer, which has good performance, long service life, low failure rate, high uniformity of material mixing, fully automatic control system, and high metering progress.

5. Cement pipe and wire pole production line

The supporting mixing system of the cement pipe and wire pole production line is a vertical axis planetary concrete mixer machine. During the material mixing process, the mixing arm performs both revolution and rotation movements. The running trajectories overlap layer by layer, and there are no dead ends in the mixing, and there will be no low-speed mixing zone. Environmentally friendly feeding device and anti-fall-body lifting.

6. Refractory production line mixing station

Hydraulic / pneumatic discharge refractory planetary mixer has advanced working form, reliable mixing uniformity, stable operation and strong scalability. It has designed a variety of auxiliary devices to meet the needs of working conditions. Optional humidity, temperature, and consistency sensors are available with advanced equipment.

Features

1. Cost-effective.

2. Optimum homogenization of mixing materials.

3. Dustproof movable covers assisted by gas springs.

4. Interlocking device and safety switch on every movable cover.

5. Interchangeable wear resistant liners with counter sunk fixing bolts.

2. Optimum homogenization of mixing materials.

3. Dustproof movable covers assisted by gas springs.

4. Interlocking device and safety switch on every movable cover.

5. Interchangeable wear resistant liners with counter sunk fixing bolts.

Product Details

Technical Parameters

Technical Data

| Item | LCPM50 | LCPM100 | LCPM150 | LCPM250 | |||

| Feeding Volume (L) | 75 | 150 | 225 | 375 | |||

| Feeding Capacity (Kg) | 120 | 240 | 360 | 600 | |||

| Output Volume (L) | 50 | 100 | 150 | 250 | |||

| Mixing Power (Kw) | 3 | 5.5 | 7.5 | 11 | |||

| Mixing Star*Blade | 1*2 | 1*2 | 1*2 | 1*2 | |||

| Side Scraper | 1 | 1 | 1 | 1 | |||

| Discharge Scraper | - | - | 1 | 1 | |||

| Discharging Power (KW) | Pneumatic Discharging Door (Hydraulic Discharge Door Optional) | ||||||

| Weight (Kg) | 750 | 1000 | 1300 | 1500 | |||

| Item | LCPM330 | LCPM500 | LCPM750 | ||||

| Feeding Volume (L) | 500 | 750 | 1125 | ||||

| Feeding Capacity (Kg) | 790 | 1200 | 1800 | ||||

| Output Volume (L) | 330 | 500 | 750 | ||||

| Mixing Power (Kw) | 15 | 18.5 | 30 | ||||

| Mixing Star*Blade | 1*2 | 1*3 | 1*3 | ||||

| Side Scraper | 1 | 1 | 1 | ||||

| Discharge Scraper | 1 | 1 | 1 | ||||

| Discharging Power (KW) | Pneumatic Discharging Door (Hydraulic Discharge Door Optional) | ||||||

| Weight (Kg) | 2000 | 2400 | 3900 | ||||

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)