High pressure cement grout pump for drilling

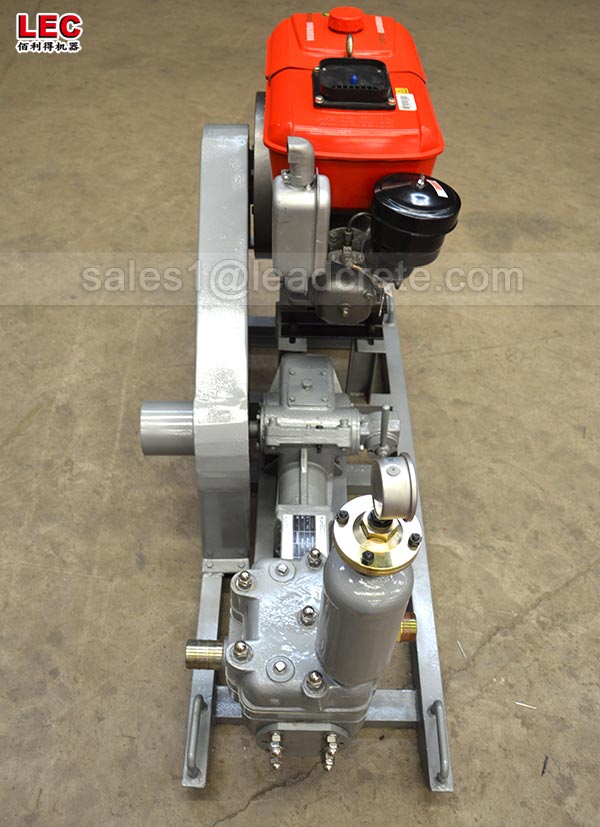

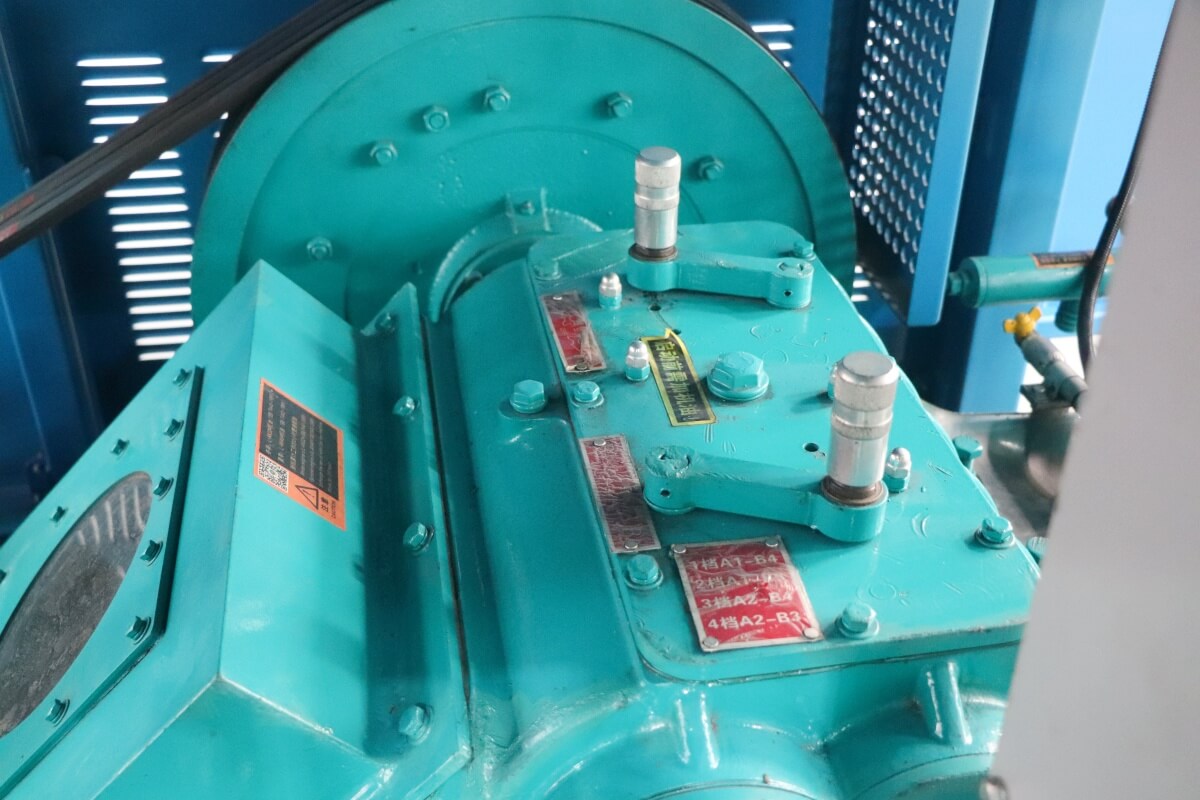

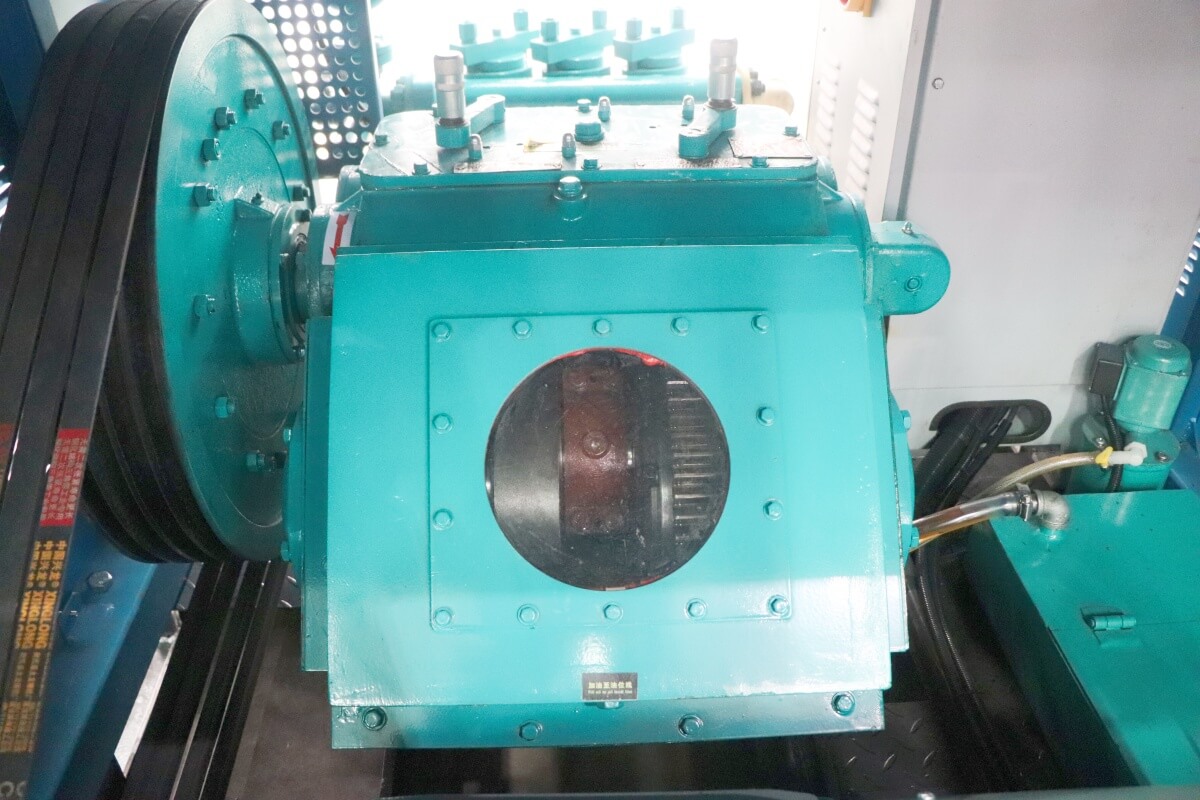

High-pressure cement grouting pumps typically employ a reciprocating piston or plunger structure. A crankshaft and connecting rod mechanism converts rotational motion into reciprocating linear motion of the piston, enabling the suction and discharge of the grout. Through the alternating action of the suction and discharge valves, the grout is compressed to a high-pressure state, and then transported through pipelines to the drill bit or grouting point.

The high-pressure cement grout pump for drilling, with its high-pressure jetting capability, intelligent control technology, multi-tube rotary jetting adaptability, and modular design, demonstrates significant advantages in drilling engineering, becoming a core equipment in fields such as foundation treatment, seepage prevention engineering, and mine remediation. The following is a detailed analysis of its technical characteristics and application value:

Technical Characteristics and Advantages:

High-Pressure Jetting Capability

The high-pressure cement grout pump for drilling adopts a high-pressure three-plunger pump structure, with an output pressure of over 50MPa, capable of easily penetrating hard soil layers, sand and gravel layers, and even soft rock. For example, in a deep foundation project in Kazakhstan, its high-pressure jetting capability effectively solved the problem of grouting reinforcement in complex geological formations.

Intelligent Control Technology

Equipped with a real-time flow and pressure monitoring system, it can dynamically adjust grouting parameters to ensure construction quality. For example, in a highway project in Turkmenistan, the intelligent control system achieved uniform improvement of foundation bearing capacity through precise control of the grout mixture ratio.

Multi-Tube Rotary Jetting Adaptability

Supports single-tube, double-tube, and triple-tube rotary jetting pile construction, meeting the technical requirements under different geological conditions. For example, in a project in Uzbekistan, the triple-tube rotary jetting technology significantly improved the pile diameter and uniformity through simultaneous high-pressure water, air, and grout injection.

Modular Design and Portability

Adopts a containerized protection system for easy transportation and rapid deployment. For example, the modular design of the XTB-280 pump allows for efficient operation even in confined spaces or remote areas, while also reducing maintenance costs.

Typical Application Scenarios of High-Pressure Cement Grout Pump for Drilling:

Foundation Reinforcement and Stabilization

Soft Soil Foundation Treatment: In weak soil layers such as silt and artificial fill, composite foundations are formed through high-pressure rotary jetting pile technology to improve bearing capacity. For example, the Zhuhai Power Plant project successfully solved the reinforcement problem of reclaimed land through double-tube high-pressure rotary jetting construction.

Existing Building Repair: For foundations cracked due to uneven settlement or mechanical damage, grouting repair restores structural integrity. For example, the Wuwei Office Building project in Gansu restored the foundation bearing capacity by filling soil pores with high-pressure grouting. Waterproofing Engineering

Underground Engineering Waterproofing: In projects such as subway tunnels and pump rooms, high-pressure grouting is used to form a waterproof curtain to prevent groundwater seepage. For example, a certain office building project in Shenyang used high-pressure jet grouting piles to replace manual excavation piles, solving the problem of underground sand gushing and simultaneously achieving waterproofing and reinforcement.

Reservoir Dam Reinforcement: High-pressure jet grouting technology is used to repair cracks in the dam body and improve waterproofing performance.

Mining and Slope Engineering

Mine Water Sealing: In mining operations, grouting is used to seal groundwater channels and prevent sudden water inflow accidents. For example, XTB series pumps are widely used in mining engineering for grouting behind wellbore walls and blocking water in tunnels.

Slope Stabilization: In highway and railway slope engineering, grouting is used to reinforce landslides and improve slope stability. For example, in a slope engineering project in Kazakhstan, high-pressure jet grouting technology effectively prevented landslide disasters.

Special Projects

MJS Method Application: Based on traditional high-pressure jet grouting technology, the MJS method uses a unique multi-hole pipe and front-end device to achieve forced drainage and underground pressure monitoring, further ensuring pile diameter and environmental safety. The combination of the XTB-280 pump and the XLT 230 drilling rig provides efficient and precise construction support for the MJS method.

Deep Foundation Engineering: In projects such as tunnel pipe shed support and deep foundation pit anchoring, XTB series pumps provide stable support for structures through high-pressure grouting technology.