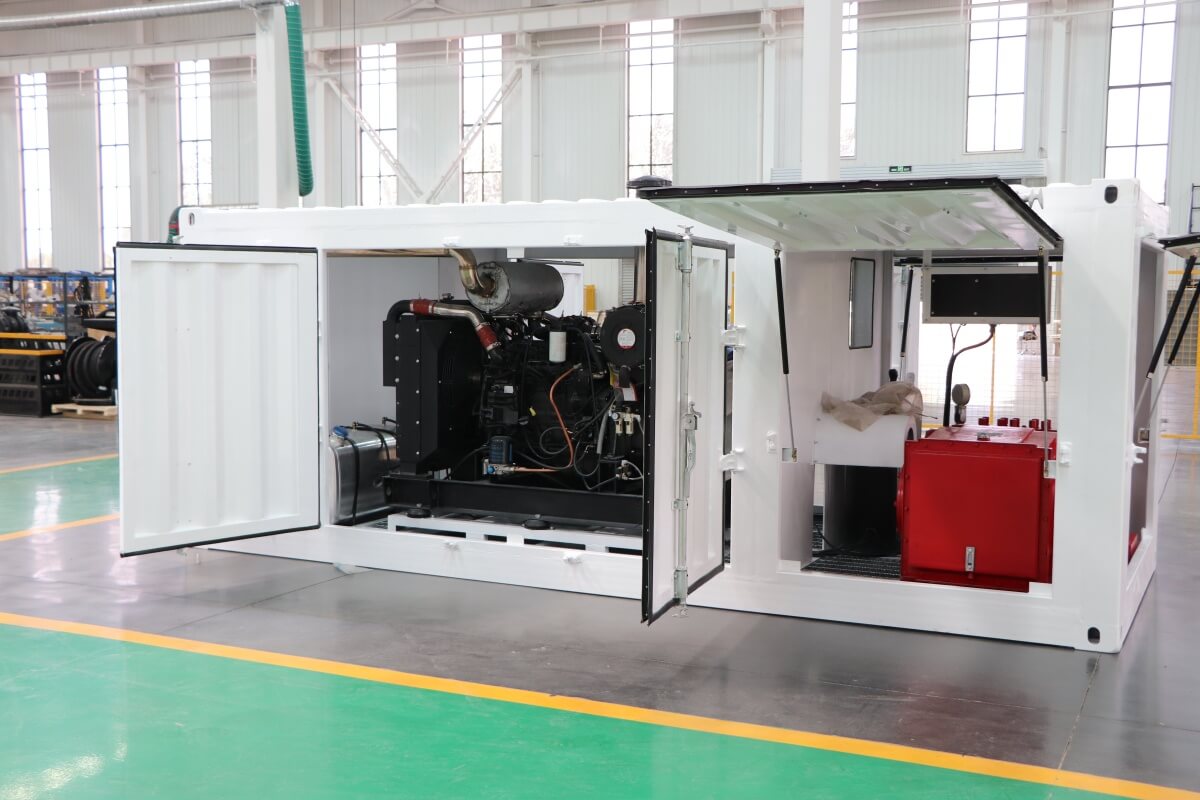

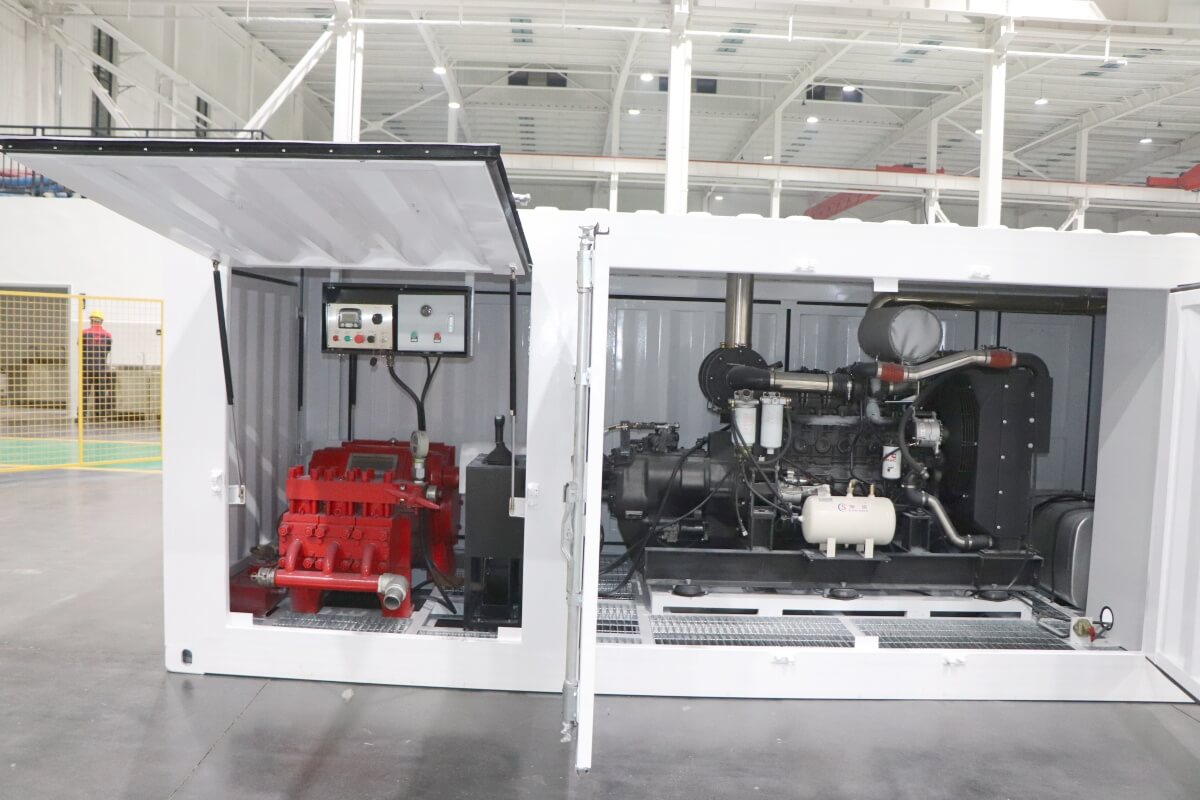

Jet grouting triplex pump

Key Features of a Jet Grouting Triplex Pump:

High-Pressure Delivery: Jet grouting requires the injection of grout at very high pressures to effectively erode and mix the in-situ soil. A triplex pump is capable of delivering the necessary pressure, often in the range of 20 to 50 MPa (or higher, depending on the specific application).

Consistent Flow Rate: The three cylinders of the triplex pump work in a coordinated manner to ensure a consistent flow rate of grout, which is crucial for maintaining the quality and uniformity of the grout columns.

Durability and Reliability: Jet grouting pumps are subjected to harsh operating conditions, including abrasive grout mixtures and high pressures. A triplex pump is designed to withstand these conditions, with robust construction and high-quality components to ensure long-term reliability.

Adjustable Parameters: The pump should allow for adjustments in pressure, flow rate, and other parameters to accommodate different soil conditions and project requirements.

Efficiency and Performance: A well-designed triplex pump will offer high efficiency and performance, minimizing energy consumption and maximizing the effectiveness of the jet grouting process.

A jet grouting triplex pump is a specialized high-pressure pump used in jet grouting operations to inject cementitious grout into the ground at extremely high pressures—often ranging from 40 MPa (5,800 psi) up to 80 MPa (11,600 psi) or more. These pumps are critical components of the jet grouting system and are designed for durability, precision, and high performance under demanding conditions.

What is a triplex pump?

The term “triplex” refers to the pump’s design, which typically incorporates three cylinders or plungers working in tandem to deliver a continuous and steady flow of grout at high pressure.

How it works in jet grouting

In a typical jet grouting process using a triplex pump:

1. A drill rod with nozzles is inserted into the ground.

2. The triplex pump delivers high-pressure grout through the drill rod.

3. As the rod is slowly rotated and withdrawn, the high-velocity grout jet erodes and mixes with the surrounding soil.

4. This creates a stabilized column of soil-grout composite, improving load-bearing capacity and reducing permeability.

Depending on the method (single-fluid, double-fluid, or triple-fluid), additional fluids like water or air may also be used alongside the grout.

Common applications of jet grouting triplex pump:

Triplex jet grouting pumps are used in various geotechnical and foundation engineering projects, including:

– Soil stabilization beneath foundations, bridges, and tunnels

– Water cutoff walls for dams or excavations

– Underpinning existing structures

– Seismic retrofitting

– Environmental remediation (e.g., containment barriers)