Jet grouting pump for foundation grouting

Jet grouting requires high-pressure pumps to inject grout at pressures typically ranging from 20 to 50 MPa (2900 to 7250 psi), depending on the soil conditions and desired grout column diameter. The pump must be capable of delivering a consistent flow rate to ensure uniform mixing of the grout with the soil.

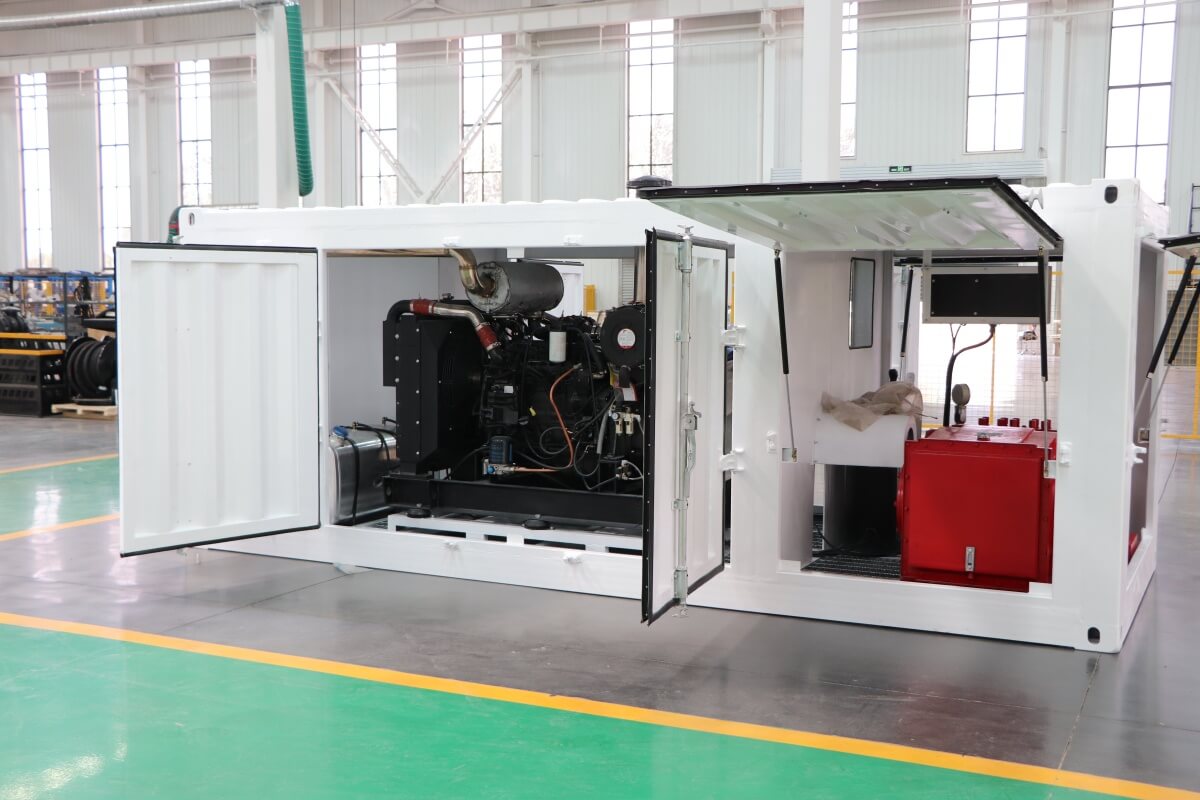

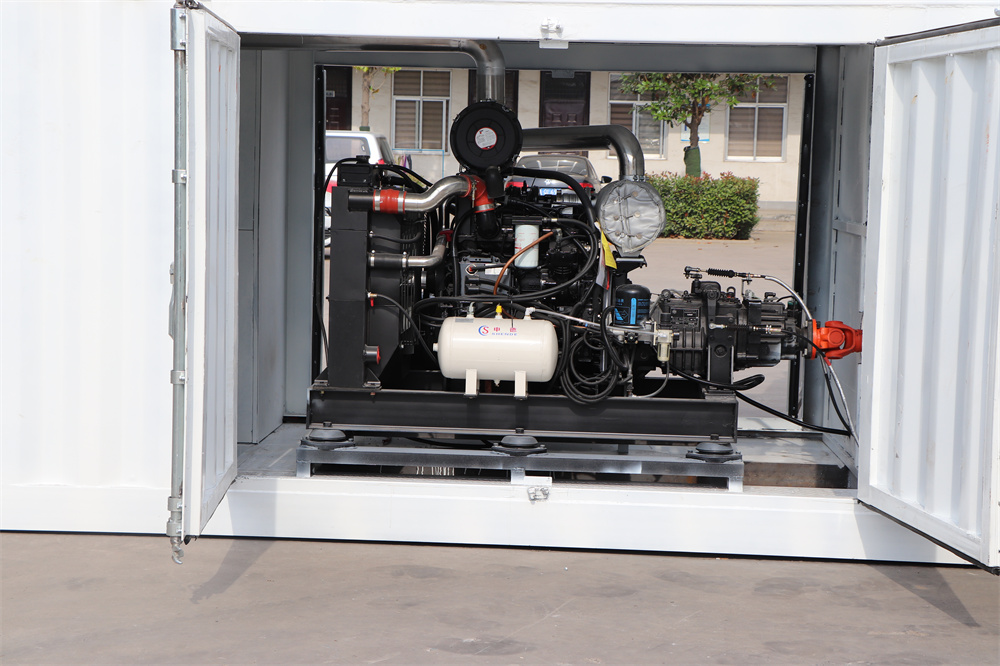

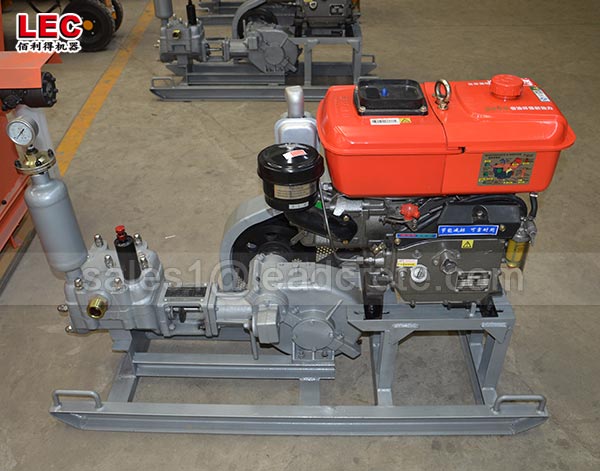

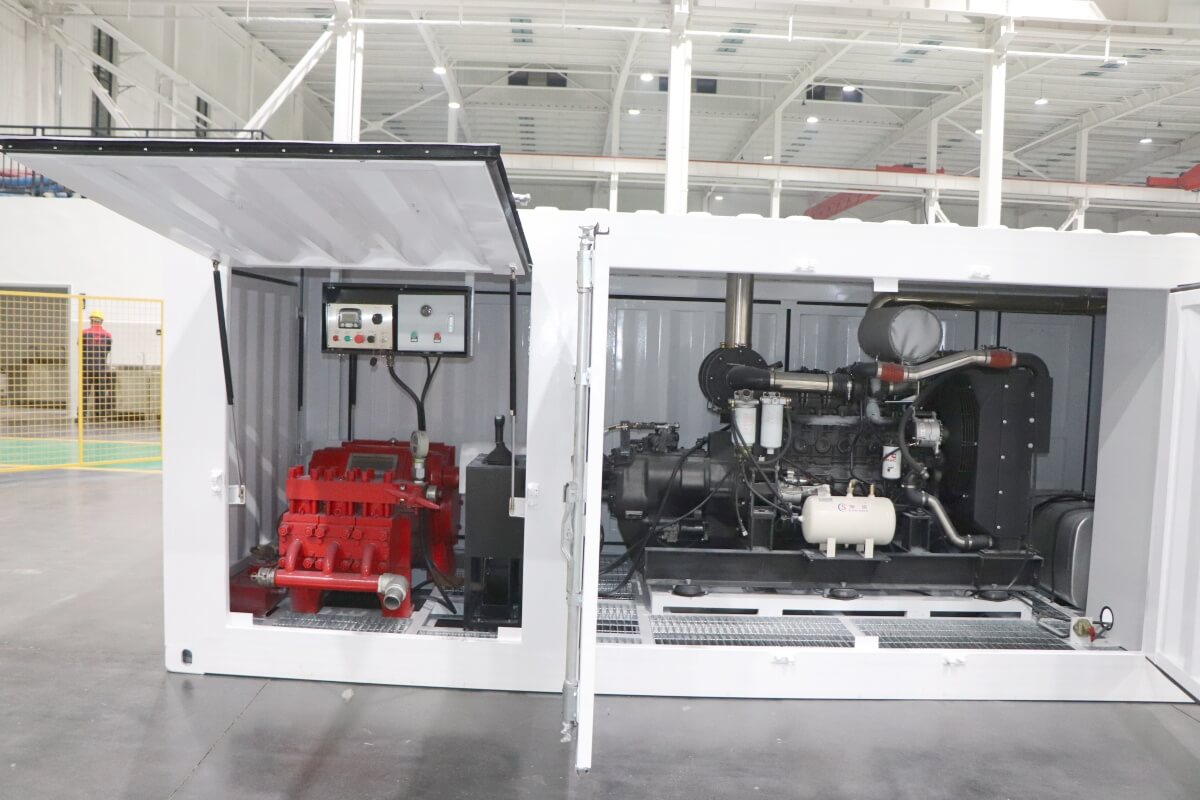

Lead Equipment are a professional jet grouting pump for foundation grouting manufacturer and supplier, and can provide you with high-quality grouting equipment for jet grouting.

Jet grouting pumps are specialized pieces of equipment used in geotechnical engineering for foundation improvement through a process known as jet grouting. This technique involves injecting a high-pressure grout mixture into the soil to create improved ground columns by eroding and mixing the in-situ soil with the grout.

Applications of jet grout pump:

Foundation Strengthening: Jet grouting is used to improve the bearing capacity of weak soils beneath existing or new foundations.

Groundwater Cutoff: It can be used to create impermeable barriers to prevent groundwater flow, which is particularly useful in tunneling or excavation projects.

Soil Stabilization: Jet grouting can stabilize loose or sandy soils, reducing the risk of settlement or liquefaction.

Features of Jet Grouting Pumps:

High Pressure: Capable of delivering grout at pressures from 20 MPa up to 80 MPa.

Precise Flow Control: Ensures consistent grout delivery during the process.

Durable Construction: Designed to handle abrasive materials and continuous operation.

Adjustable Output: Allows operators to change pressure and flow rate based on soil conditions.

If you’re looking to purchase or rent a jet grouting pump for jet grouting, or need advice on selecting the right equipment for your project, I can help guide you based on technical specifications, manufacturer options, or application requirements. Let me know what you’re working on! Email address: sales1@leadcrete.com