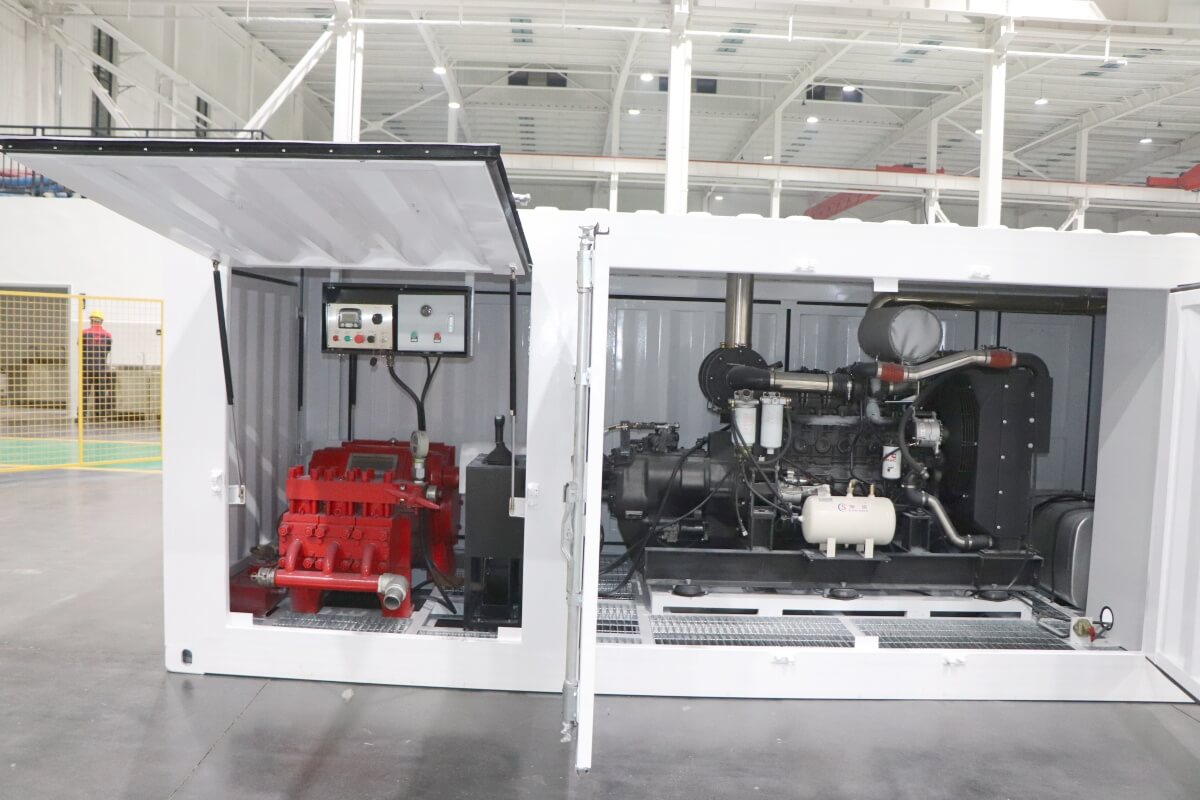

High pressure cement grouting station

Applications of high pressure cement grouting station: Soil Stabilization: Improving bearing capacity of weak or compressible soils. Groundwater Control: Sealing leaks in dams, tunnels, or basements. Structural Repair: Filling voids or cracks in concrete structures. Mining and Tunneling: Reinforcing rock masses and preventing water ingress. Foundation Underpinning: Strengthening existing foundations or correcting settlement issues.

A high-pressure cement grouting station is a critical piece of equipment in modern geotechnical and civil engineering. Its ability to deliver precise, high-pressure grout injections makes it indispensable for projects requiring ground improvement, water control, or structural rehabilitation.

High pressure cement grouting station is an equipment system specially designed to perform efficient and high-quality cement grouting operations. It is usually used in construction projects that require strengthening the foundation, preventing leakage or repairing structural damage, such as tunnel construction, waterproofing of underground buildings, and foundation improvement of infrastructure such as bridges and dams.

High pressure cement grouting station application:

Foundation treatment: Enhance the bearing capacity of weak foundations and reduce building settlement.

Waterproofing and plugging: Waterproofing in underground structures such as basements and subway tunnels to prevent groundwater infiltration.

Structural repair: Repair concrete structures with cracks or other damage to restore their original strength and stability.

Slope stability: Improve the stability of slopes and prevent geological disasters through grouting reinforcement technology.

Advantages of high pressure cement grouting station:

High Efficiency: Rapid mixing and injection reduce project timelines.

Precision: Controlled pressure and flow ensure accurate grout placement.

Versatility: Suitable for a wide range of grout mixtures and applications.

Durability: Enhances the long-term stability of structures and ground conditions.

Considerations for Selection

Project Requirements: Pressure, flow rate, and grout type needed.

Mobility: Stationary vs. mobile units for different job site conditions.

Automation Level: Manual vs. fully automated systems for efficiency.

Safety Standards: Compliance with local regulations and industry best practices.