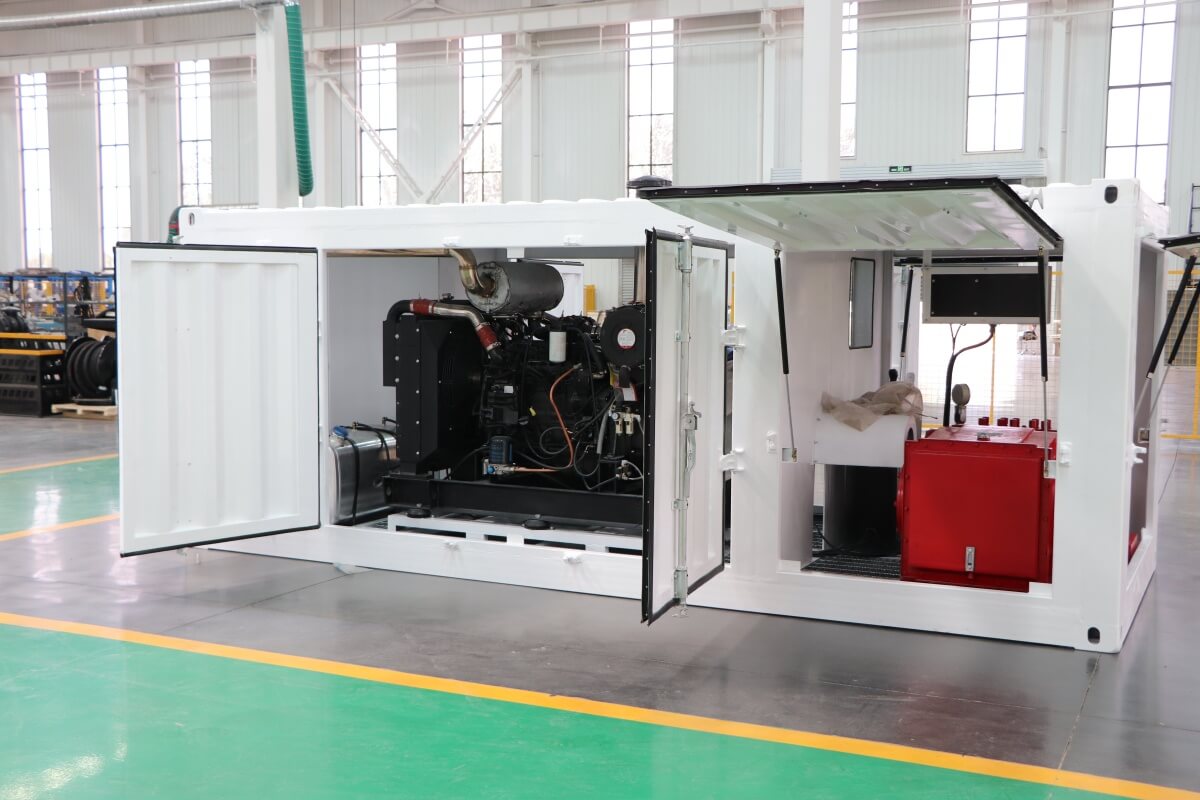

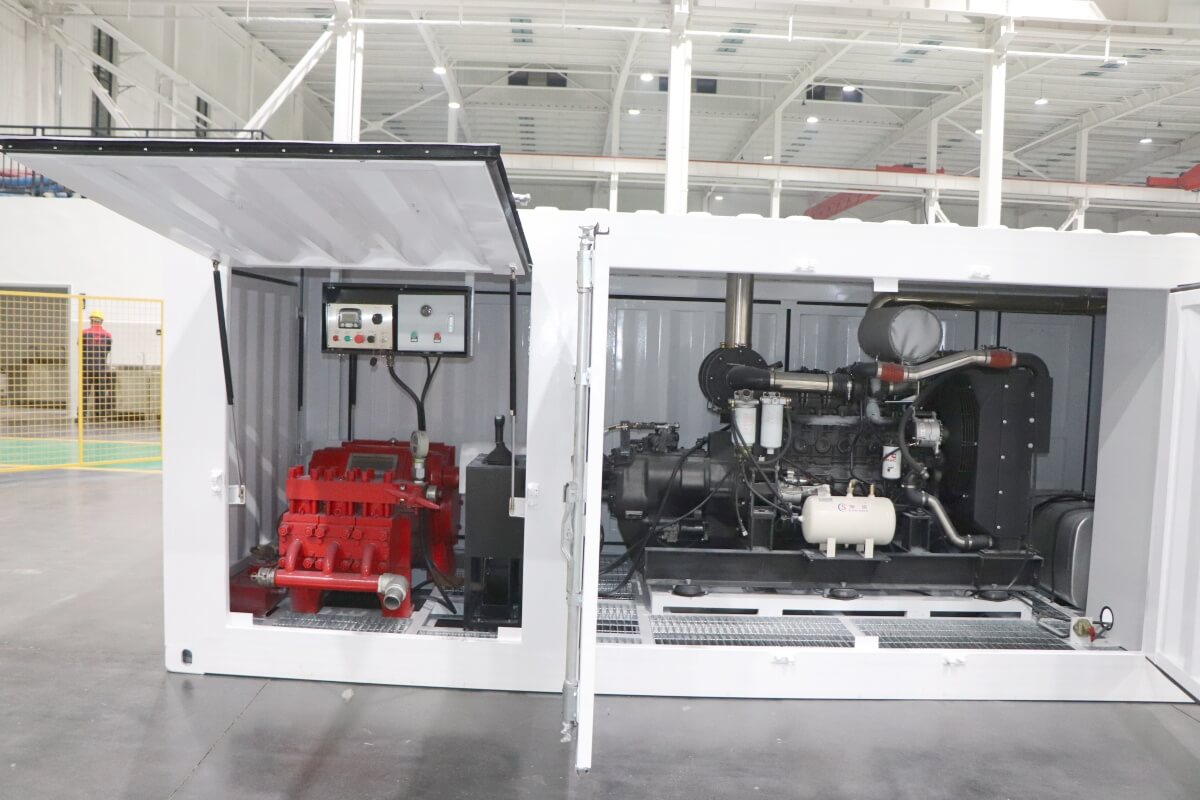

Diesel jet grouting pump

Diesel jet grouting pump uses diesel engine as power source, which enables the equipment to work normally in remote areas without electricity supply or unstable electricity supply. It can generate enough pressure to achieve efficient jet grouting operation, usually reaching pressure level of tens or even hundreds of MPa, ensuring that the grout can penetrate deep into the cracks of the formation. It is suitable for various types of soil conditions, whether it is loose sand or hard rock, and the construction parameters can be adjusted according to the actual situation. Due to the changeable and harsh use environment, diesel jet grouting pumps are generally made of strong and durable materials and are strictly tested to ensure their reliability and long life.

Diesel jet grouting pump is a high-pressure grouting equipment powered by a diesel engine. Its core feature is that it can achieve efficient and stable grouting operations through diesel engine drive. It is suitable for soil reinforcement, waterproofing and structural reinforcement in tunnels, mines, underground projects and other fields. Using a diesel engine as a power source has the advantages of high power, strong adaptability, and no need for external power supply. It is especially suitable for construction environments in the field or where power supply is inconvenient. Cement slurry, chemical slurry and other media are injected into the formation at high speed through a high-pressure pump body, and the penetration, filling and solidification of the slurry are used to improve the physical and mechanical properties of the foundation or surrounding rock. The equipment is usually equipped with an adjustable pressure and flow control system, which can accurately control the grouting parameters according to geological conditions and engineering requirements to ensure the grouting effect.

Diesel jet grouting pump application:

Foundation treatment: Improve the bearing capacity and stability of weak foundations and reduce the settlement of buildings after completion.

Waterproof engineering: Used for waterproofing of underground structures such as basements and tunnels to prevent groundwater infiltration.

Slope reinforcement: Enhance the stability of slopes or mountains to prevent geological disasters such as landslides.

Underground obstacle removal: Cut and mix the surrounding soil or small stones through high-pressure water flow to form a columnar consolidation body.

When selecting a suitable diesel jet grouting pump, it is necessary to consider factors such as the specific geological conditions of the project, the required grouting depth, and the expected reinforcement effect to ensure that the selected equipment can meet the actual needs of the project. At the same time, the professional skills and experience of the operator are also important factors affecting the quality and efficiency of construction. Email address: sales1@leadcrete.com