Your position:

Home > Products > Hydraulic Jack

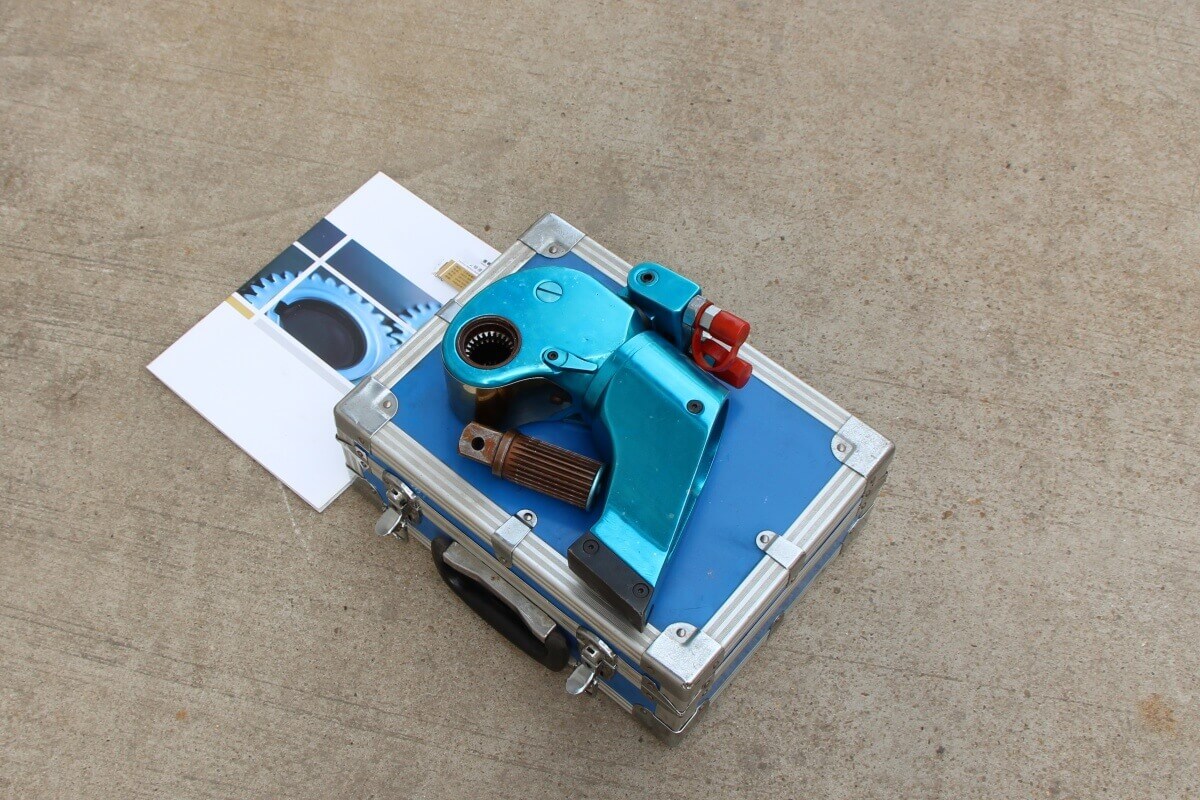

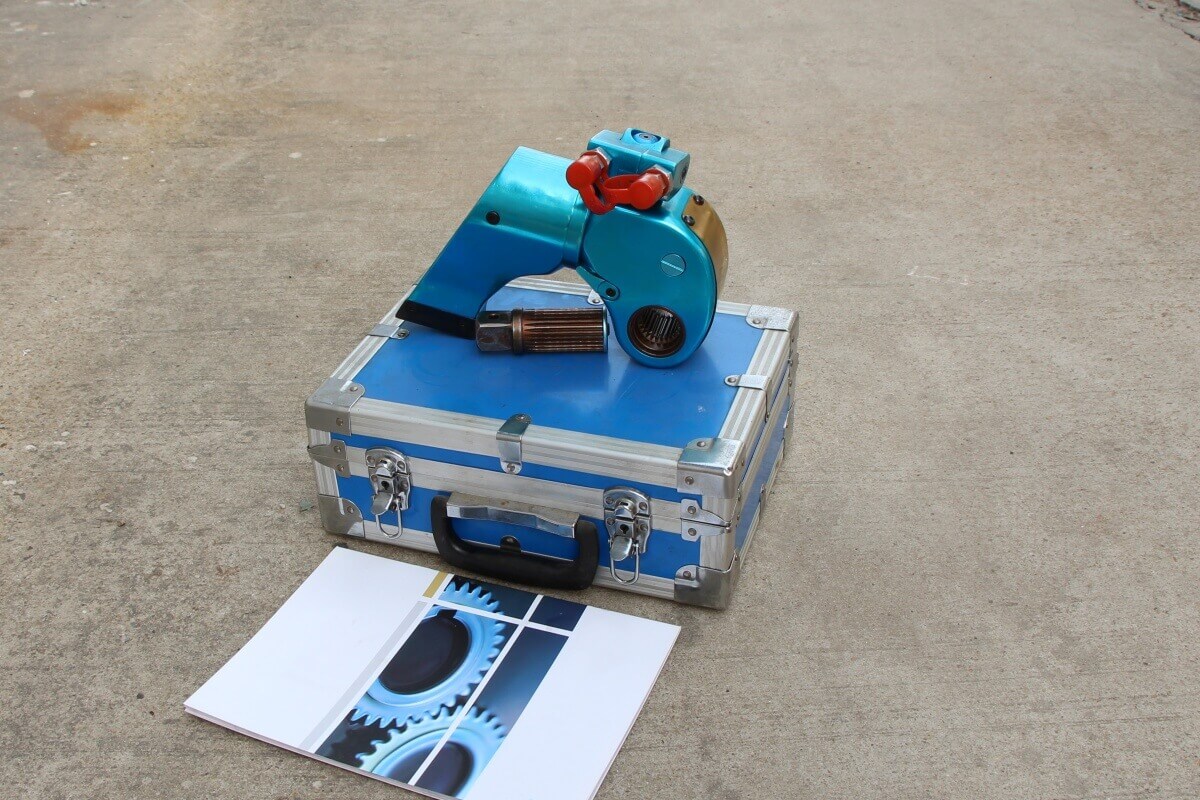

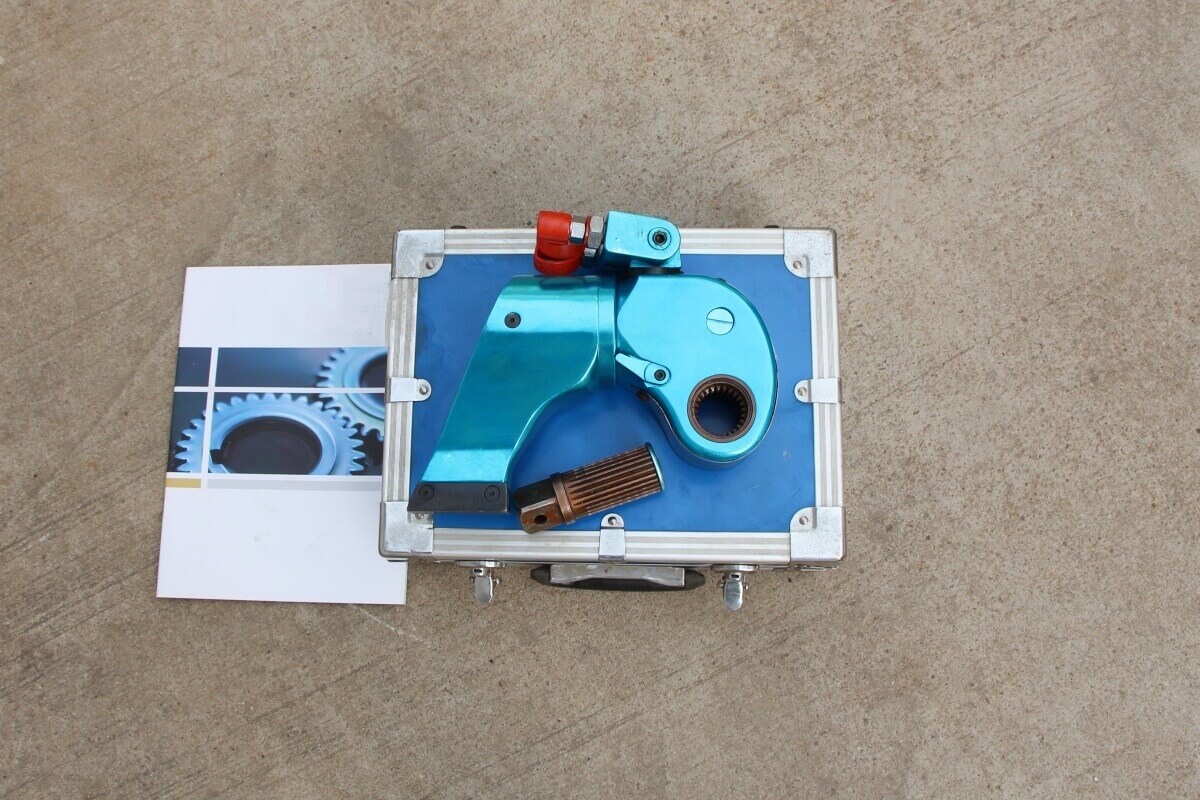

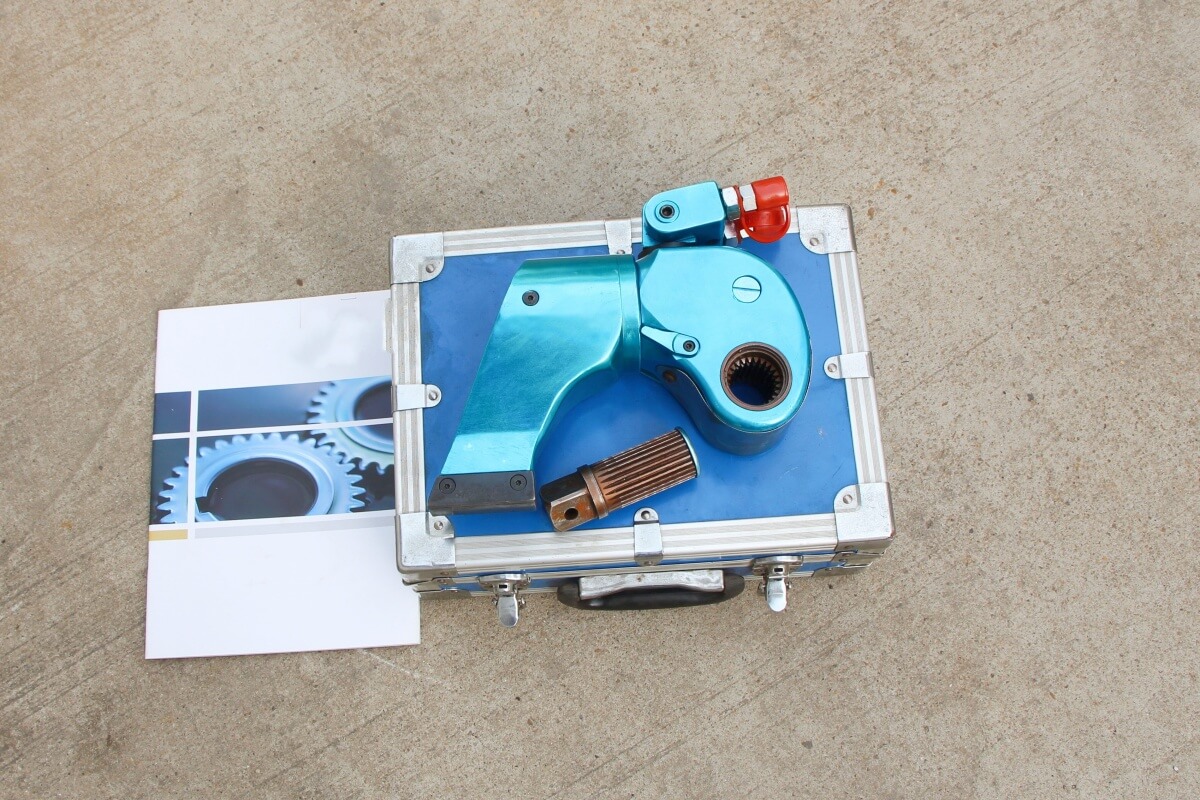

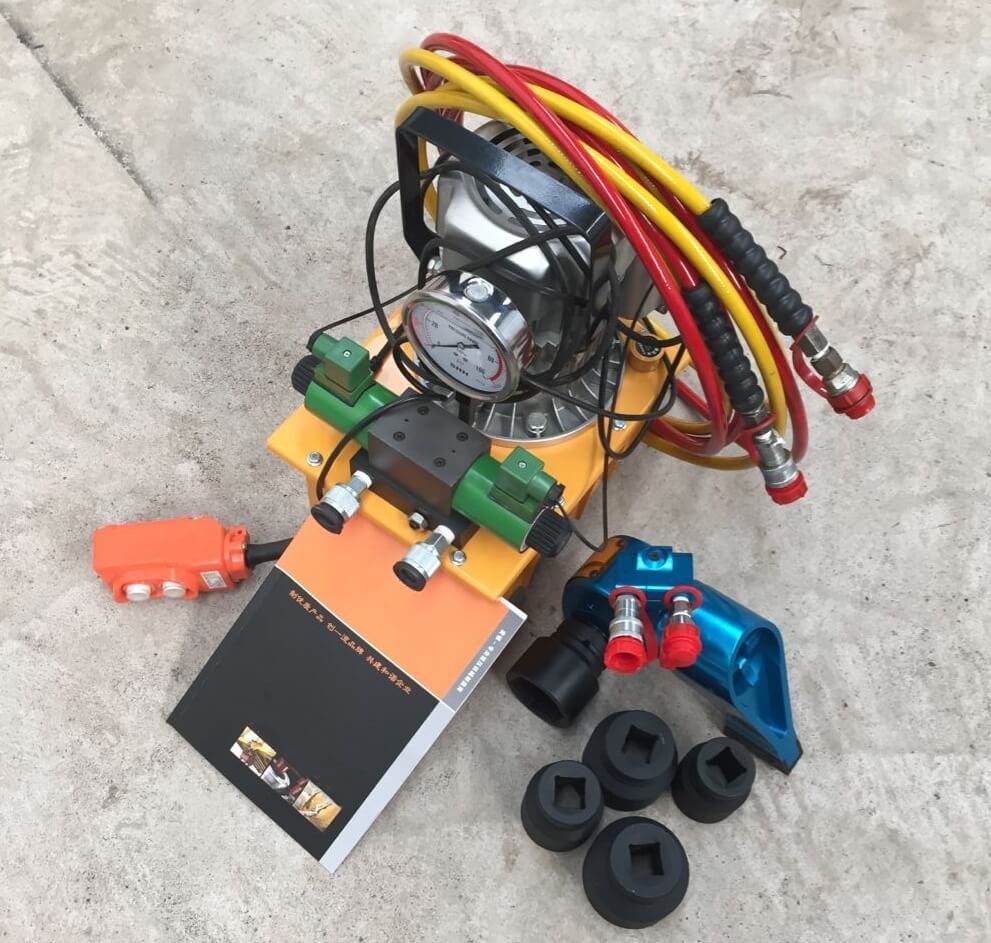

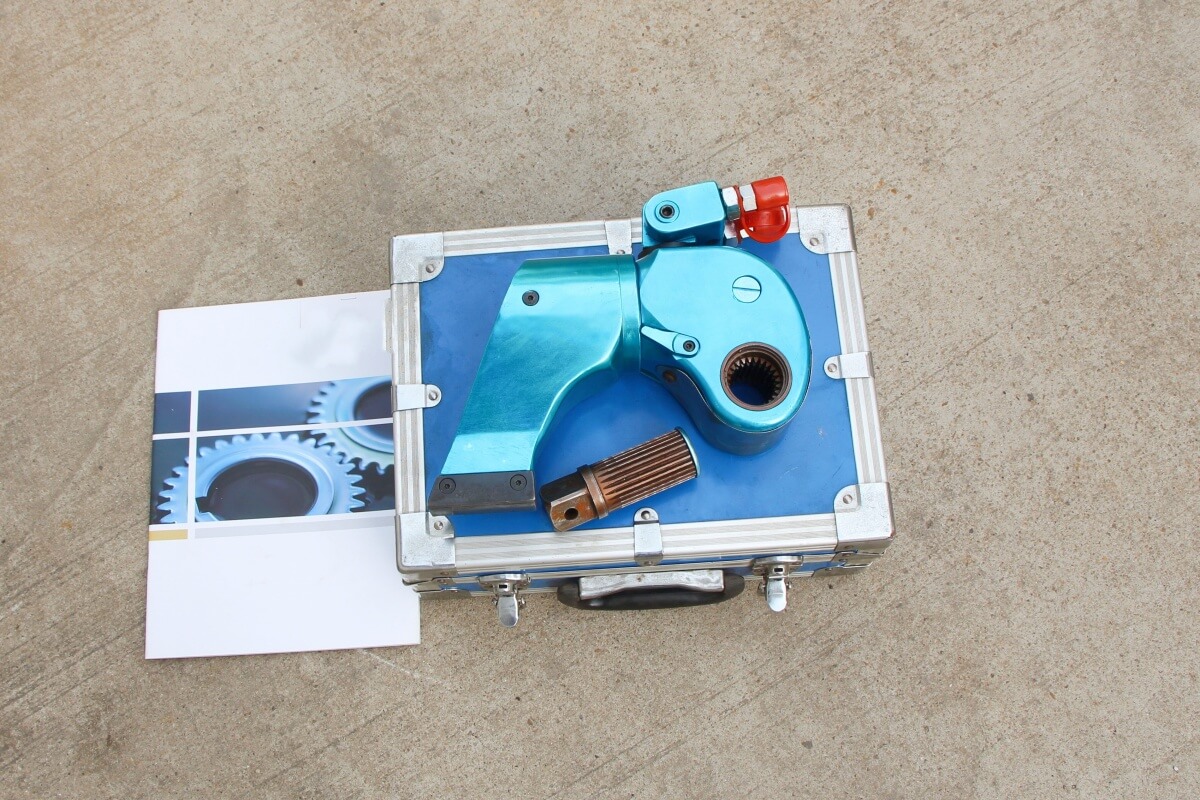

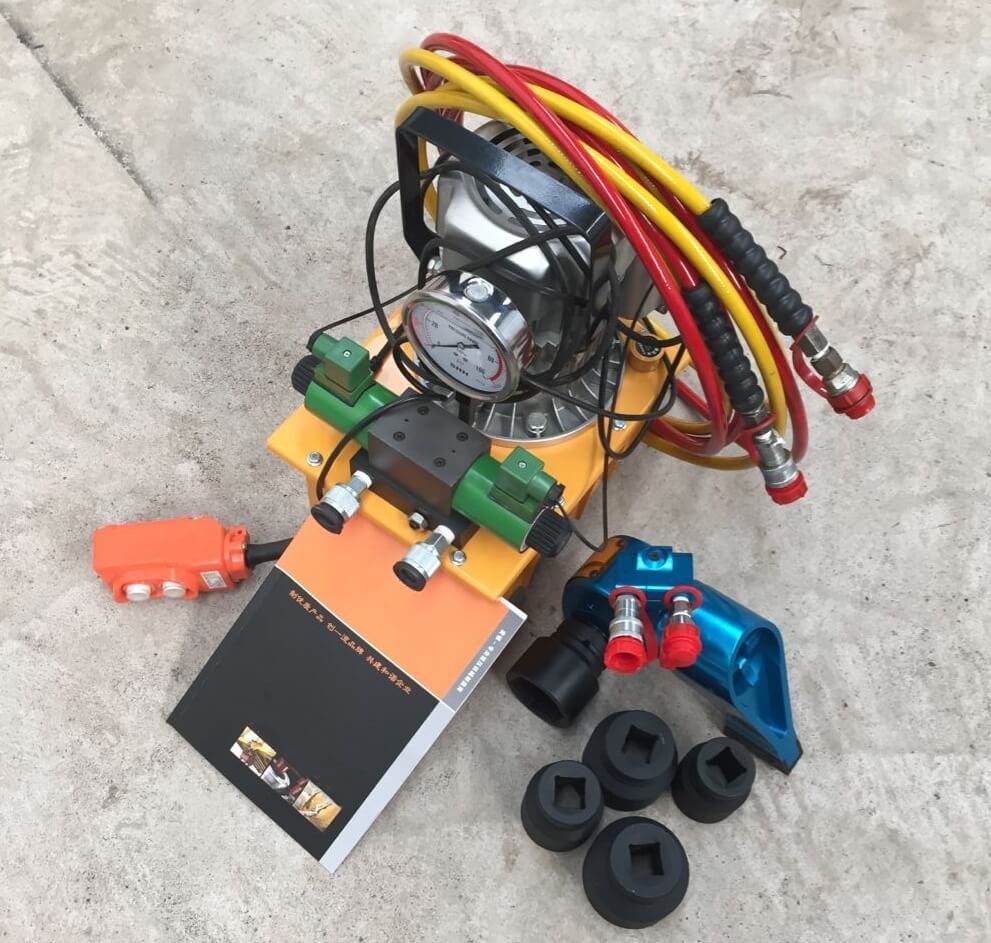

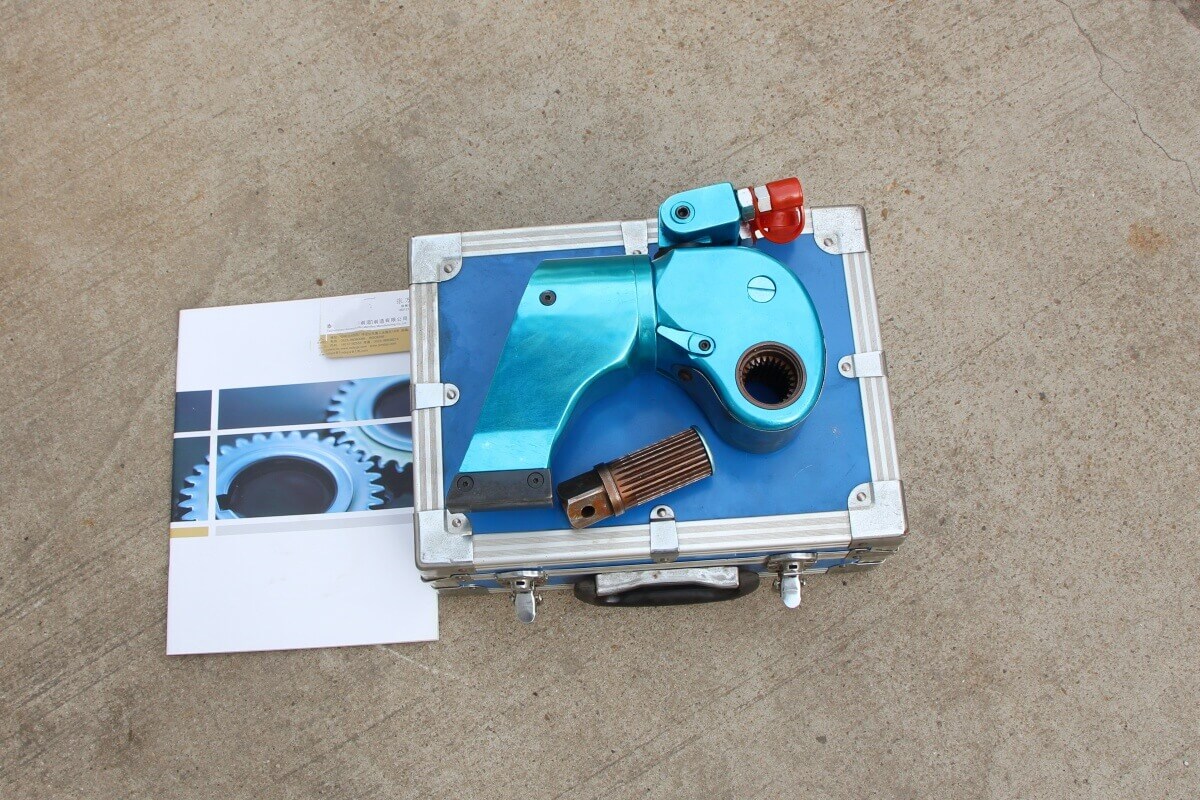

Aluminum titanium alloy body hydraulic torque wrench

Aluminum titanium alloy body hydraulic torque wrench is made of aluminum titanium alloy and ultra-high strength alloy materials. It is manual controlled and double-acting hydraulic design, which can lock and loosen bolt connection.

MTH70

70660

7066

90

2-1/2"

63.2

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

This high-performance aluminum titanium alloy body hydraulic torque wrench is meticulously constructed from premium aluminum titanium alloy, delivering exceptional durability and robustness to endure the most demanding industrial applications. With an impressive maximum torque capacity of 70660Nm, this metric-system torque wrench empowers users to execute heavy-duty tasks requiring precision and reliability.

The hydraulic torque wrench tool is thoughtfully packed in wooden cases, offering robust protection during transit and storage while minimizing damage risks. Additionally, the hydraulic torque wrench supports OEM/ODM customization, enabling businesses to tailor the wrench to their unique operational requirements and benefit from specialized tooling solutions.

1. Aluminum-titanium alloy integrally formed fuselage

Material advantages: The yield strength of aluminum-titanium alloy (such as Ti-6Al-4V) can reach 880MPa, which is 40% higher than that of traditional aluminum alloy. At the same time, the density is only 4.5g/cm³ (60% of steel), achieving a balance between lightweight and high load-bearing capacity.

One-piece molding process: Through precision forging or CNC processing to form a weld-free structure, eliminate stress concentration points, and increase fatigue life to 10^5 cycles without failure.

2. 360°X180° rotating hydraulic joint

Spatial adaptability: The dual-degree-of-freedom rotation design (axial 360° + radial 180°) can bypass obstacles and is suitable for narrow scenarios with a flange gap of only 50mm.

Sealing performance: It adopts a double-layer O-ring + metal sealing ring structure, with a pressure of 70MPa without leakage, and adapts to a working environment of -40℃~120℃.

3. Precision anti-reverse ratchet mechanism

Torque control: 24-tooth precision ratchet achieves ±3% torque accuracy, and the hydraulic feedback system can control the preload in a closed loop.

Safety mechanism: The one-way clutch prevents the bolt from rebounding and causing the tool to reverse. The response speed is less than 0.1 seconds, which improves the safety of operation.

4. Humanized operation design

Visual torque meter: The dial is integrated into the wrench head, using fluorescent scale + digital dual display, and the reading error in dark light environment is less than 5%.

Modular switching: supports quick replacement of open-end wrench heads (opening range 10mm~150mm) or locking chucks to adapt to bolts of different specifications.

5. Customized drive system

Drive shaft customization: Provides a variety of drive interfaces such as square, hexagonal, spline, etc., supporting maximum M120 bolts (torque requirement > 50,000Nm).

Extension rod solution: The reaction arm can be extended to 2 meters to solve the tightening problem of deep hole bolts (> 1.5 meters).

6. Mobile control system

Wireless control: equipped with Bluetooth module, supports remote setting of torque value (accuracy ±1%), operating distance > 100 meters.

Portable design: The integrated pump station weighs < 15kg, equipped with universal wheels + telescopic handle, and can be dragged to the work site by one person.

The hydraulic torque wrench tool is thoughtfully packed in wooden cases, offering robust protection during transit and storage while minimizing damage risks. Additionally, the hydraulic torque wrench supports OEM/ODM customization, enabling businesses to tailor the wrench to their unique operational requirements and benefit from specialized tooling solutions.

1. Aluminum-titanium alloy integrally formed fuselage

Material advantages: The yield strength of aluminum-titanium alloy (such as Ti-6Al-4V) can reach 880MPa, which is 40% higher than that of traditional aluminum alloy. At the same time, the density is only 4.5g/cm³ (60% of steel), achieving a balance between lightweight and high load-bearing capacity.

One-piece molding process: Through precision forging or CNC processing to form a weld-free structure, eliminate stress concentration points, and increase fatigue life to 10^5 cycles without failure.

2. 360°X180° rotating hydraulic joint

Spatial adaptability: The dual-degree-of-freedom rotation design (axial 360° + radial 180°) can bypass obstacles and is suitable for narrow scenarios with a flange gap of only 50mm.

Sealing performance: It adopts a double-layer O-ring + metal sealing ring structure, with a pressure of 70MPa without leakage, and adapts to a working environment of -40℃~120℃.

3. Precision anti-reverse ratchet mechanism

Torque control: 24-tooth precision ratchet achieves ±3% torque accuracy, and the hydraulic feedback system can control the preload in a closed loop.

Safety mechanism: The one-way clutch prevents the bolt from rebounding and causing the tool to reverse. The response speed is less than 0.1 seconds, which improves the safety of operation.

4. Humanized operation design

Visual torque meter: The dial is integrated into the wrench head, using fluorescent scale + digital dual display, and the reading error in dark light environment is less than 5%.

Modular switching: supports quick replacement of open-end wrench heads (opening range 10mm~150mm) or locking chucks to adapt to bolts of different specifications.

5. Customized drive system

Drive shaft customization: Provides a variety of drive interfaces such as square, hexagonal, spline, etc., supporting maximum M120 bolts (torque requirement > 50,000Nm).

Extension rod solution: The reaction arm can be extended to 2 meters to solve the tightening problem of deep hole bolts (> 1.5 meters).

6. Mobile control system

Wireless control: equipped with Bluetooth module, supports remote setting of torque value (accuracy ±1%), operating distance > 100 meters.

Portable design: The integrated pump station weighs < 15kg, equipped with universal wheels + telescopic handle, and can be dragged to the work site by one person.

Application

Aluminum titanium alloy body hydraulic torque wrench improves the efficiency of hydraulic torque wrench by more than 30% through the collaborative innovation of materials, structure and control system. It is particularly suitable for industrial scenarios with extremely high requirements for precision, safety and spatial adaptability.

Typical application scenarios of aluminum titanium alloy body hydraulic torque wrench:

1. Nuclear power equipment: reactor pressure vessel bolt tightening (torque> 30,000Nm, accuracy ±1.5%).

2. Offshore wind power: synchronous pre-tightening of single pile foundation bolt group (128 M64 bolts, error <5%).

3. Chemical pipeline: high-pressure flange (PN400) sealing operation (gap <3mm, 3 people are required to work together).

Typical application scenarios of aluminum titanium alloy body hydraulic torque wrench:

1. Nuclear power equipment: reactor pressure vessel bolt tightening (torque> 30,000Nm, accuracy ±1.5%).

2. Offshore wind power: synchronous pre-tightening of single pile foundation bolt group (128 M64 bolts, error <5%).

3. Chemical pipeline: high-pressure flange (PN400) sealing operation (gap <3mm, 3 people are required to work together).

Features

1. The aluminum-titanium alloy body is highly strengthened and integrally molded. Strengthen the body for durability.

2. 700 bar maximum working pressure.

3. Designing using 3D CAD modeling software, provide torque precision within ±3%.

4. 360° multi-positional swivel quick-release couplings.

5. Working with the high resistance sockets, suitable for more size of screws.

6. The quick-release square drive allows you to switch from tightening and loosening without any other special tools.

7. 360°Adjustable reaction arm with safety lock feature, can be used without reaction arm.

2. 700 bar maximum working pressure.

3. Designing using 3D CAD modeling software, provide torque precision within ±3%.

4. 360° multi-positional swivel quick-release couplings.

5. Working with the high resistance sockets, suitable for more size of screws.

6. The quick-release square drive allows you to switch from tightening and loosening without any other special tools.

7. 360°Adjustable reaction arm with safety lock feature, can be used without reaction arm.

Product Details

Technical Parameters

Technical Data

| Item | MTH02 | MTH05 | MTH08 | MTH10 | MTH16 | MTH20 | MTH28 | MTH36 | MTH50 | MTH70 |

| Max. torque(Nm) | 1882 | 4466 | 7451 | 10732 | 15339 | 20108 | 26392 | 35397 | 48740 | 70660 |

| Min. torque(Nm) | 188 | 447 | 745 | 1073 | 1536 | 2011 | 2639 | 3540 | 4874 | 7066 |

| Screw Nut(mm) | 16-36 | 22-48 | 27-55 | 30-64 | 36-72 | 42-90 | 42-90 | 48-100 | 64-120 | 90 |

| Square Drive | 3/4" | 1" | 1-1/2" | 1-1/2" | 1-1/2" | 2-1/2" | 2-1/2" | 2-1/2" | 2-1/2" | 2-1/2" |

| L1(mm) | 130 | 170 | 202 | 228 | 237 | 273 | 287 | 323 | 351 | 376 |

| L2(mm) | 182 | 249 | 286 | 326 | 336 | 391 | 433 | 464 | 494 | 528 |

| H1(mm) | 52 | 70 | 81 | 90 | 100 | 110 | 120 | 138 | 153 | 162 |

| H2(mm) | 77 | 98 | 125 | 134 | 144 | 134 | 187 | 206 | 279 | 291 |

| H3(mm) | 96 | 127 | 149 | 172 | 181 | 206 | 221 | 258 | 279 | 291 |

| H4(mm) | 133 | 165 | 184 | 207 | 216 | 241 | 256 | 293 | 315 | 326 |

| R1(mm) | 25.8 | 34.8 | 39.8 | 16.8 | 50.8 | 56.8 | 59.8 | 70.8 | 76.8 | 78.9 |

| R2(mm) | 102 | 140 | 160 | 184 | 192 | 223 | 248 | 256 | 271 | 295 |

| Weight(kg) | 1.7 | 3.8 | 6.6 | 9 | 12.9 | 24.5 | 24.5 | 30.7 | 44.8 | 63.2 |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

Double acting hydraulic cylinder for sale is powered by ZB series of high pressure electric oil pump, the function for oil pressure rebound, overflow, double acting hydraulic cylinder for sale is designed a safe protect pressurizer, it can protect emergent overpressure, especial construction can protect jack.Double Acting Hydraulic Cylinder for Sale

Double acting hydraulic cylinder for sale is powered by ZB series of high pressure electric oil pump, the function for oil pressure rebound, overflow, double acting hydraulic cylinder for sale is designed a safe protect pressurizer, it can protect emergent overpressure, especial construction can protect jack.Double Acting Hydraulic Cylinder for Sale -

This electric hydraulic oil pump for tensioning jack is a complete hydraulic power pack, it is made of oil pump, control valve, oil box, motor, oil gauge and etc. Compact structure, powerful function, small size, light weight, and convenient use High working pressure.Electric Hydraulic Oil Pump for Tensioning Jack

This electric hydraulic oil pump for tensioning jack is a complete hydraulic power pack, it is made of oil pump, control valve, oil box, motor, oil gauge and etc. Compact structure, powerful function, small size, light weight, and convenient use High working pressure.Electric Hydraulic Oil Pump for Tensioning Jack -

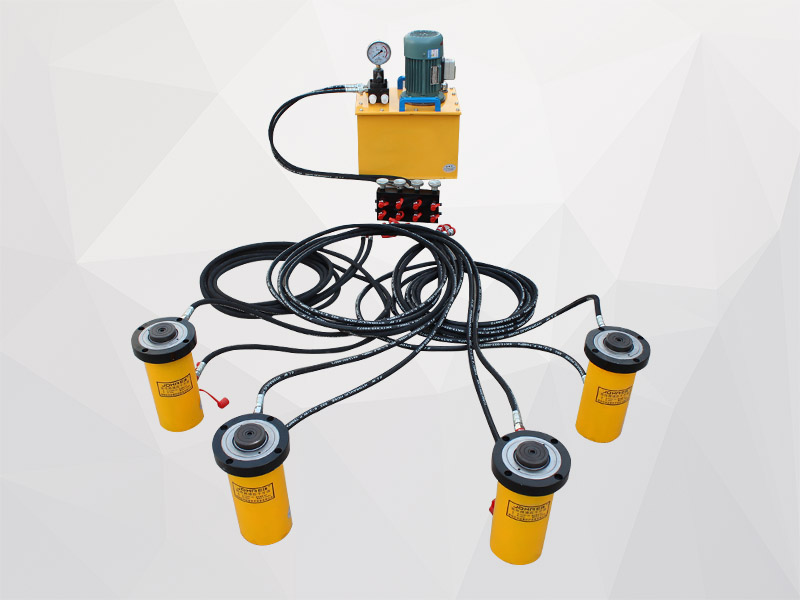

Hydraulic synchronous lifting jack is powered by ZB series of high pressure electric oil pump, the function for oil pressure rebound, overflow, hydraulic synchronous lifting jack is designed a safe protect pressurizer, it can protect emergent overpressure, especial construction can protect the cylinder. Hydraulic synchronous lifting jack can bear partial loading is 5% of rated pressure. High pressure alloy cylinder is very durable, especially in the larger project, it is easy to be operated and control.Hydraulic Synchronous Lifting Jack

Hydraulic synchronous lifting jack is powered by ZB series of high pressure electric oil pump, the function for oil pressure rebound, overflow, hydraulic synchronous lifting jack is designed a safe protect pressurizer, it can protect emergent overpressure, especial construction can protect the cylinder. Hydraulic synchronous lifting jack can bear partial loading is 5% of rated pressure. High pressure alloy cylinder is very durable, especially in the larger project, it is easy to be operated and control.Hydraulic Synchronous Lifting Jack -

Single acting hydraulic jack for sale around world, it is a hot product of hydraulic jack manufacturer Lead Equipment Co., Ltd . Single acting hydraulic jack for sale is single outlet, high low pressure pump, parallel type hydraulic power pack, high- low pressure pump supply oil at the same time when low pressure, single acting hydraulic jack can get the large output flow; low pressure pump automatically unloading back the oil via control valve when high pressure, it can reduce the consumption of electric motor and heat of oil, it has the function of stop machine to protect pressure, single oil-way backing oil and etc.Single Acting Hydraulic Jack for Sale

Single acting hydraulic jack for sale around world, it is a hot product of hydraulic jack manufacturer Lead Equipment Co., Ltd . Single acting hydraulic jack for sale is single outlet, high low pressure pump, parallel type hydraulic power pack, high- low pressure pump supply oil at the same time when low pressure, single acting hydraulic jack can get the large output flow; low pressure pump automatically unloading back the oil via control valve when high pressure, it can reduce the consumption of electric motor and heat of oil, it has the function of stop machine to protect pressure, single oil-way backing oil and etc.Single Acting Hydraulic Jack for Sale

.jpg)

.jpg)

.JPG)