Your position:

Home > Products > Mortar Spraying Machine

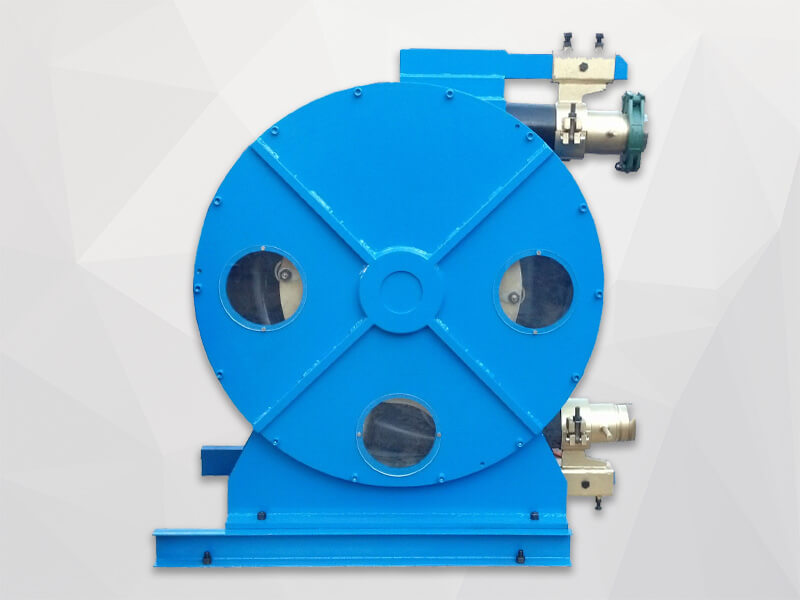

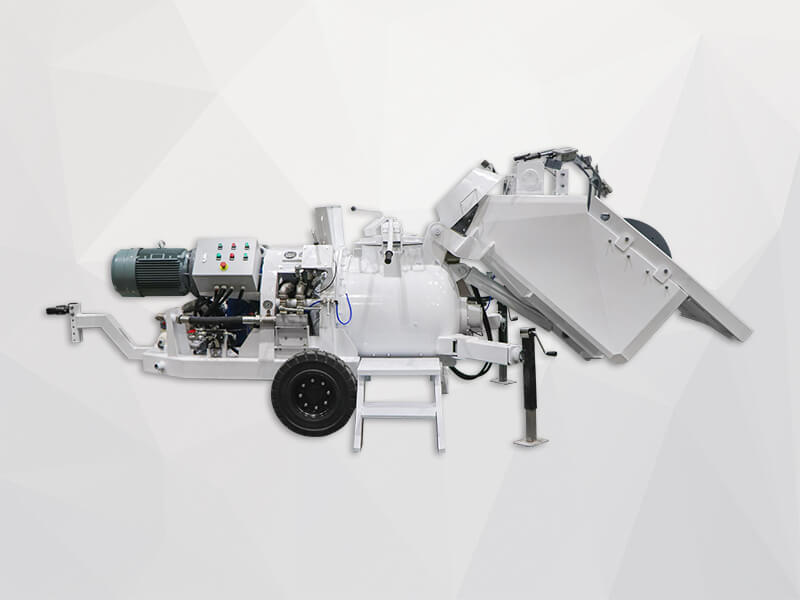

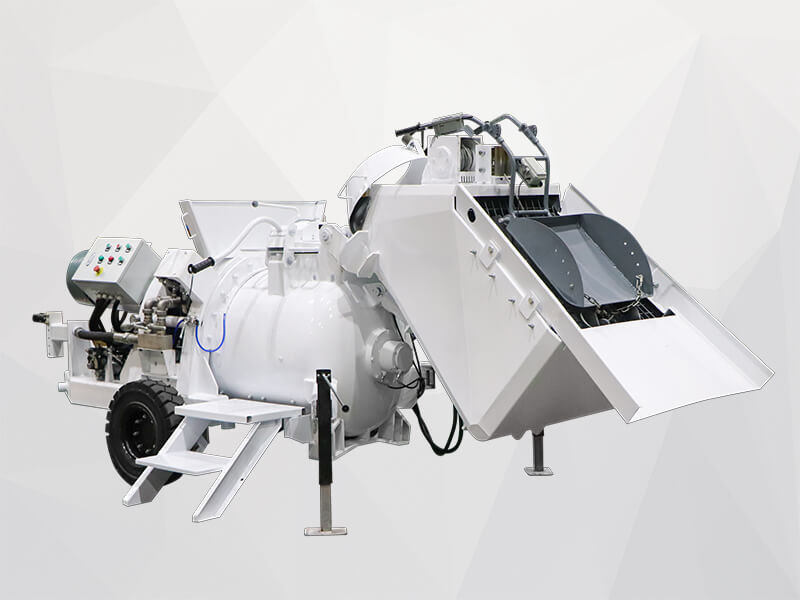

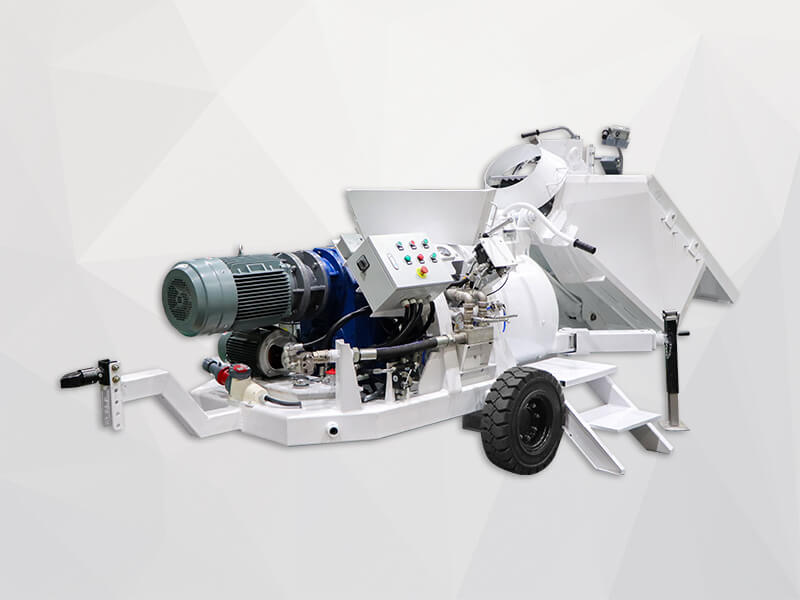

LPXT400-E Dry floor-screed conveying machine

The LPXT400-E Dry floor-screed conveying machine can precisely transport dry-mixed mortar, cement-based materials, etc., from storage or mixing locations to the construction site, significantly reducing labor intensity and improving construction accuracy.

LPXT400-E

22KW

4KW

380V, 50HZ

Gross 520L / Net 400L

9m³/h

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LPXT400-E Dry floor-screed conveying machine is a high-performance dry mortar conveying system designed specifically for construction engineering, aiming to provide continuous and stable material conveying services on construction sites. With its superior power system and innovative design concept, this model has become a powerful assistant in modern construction.

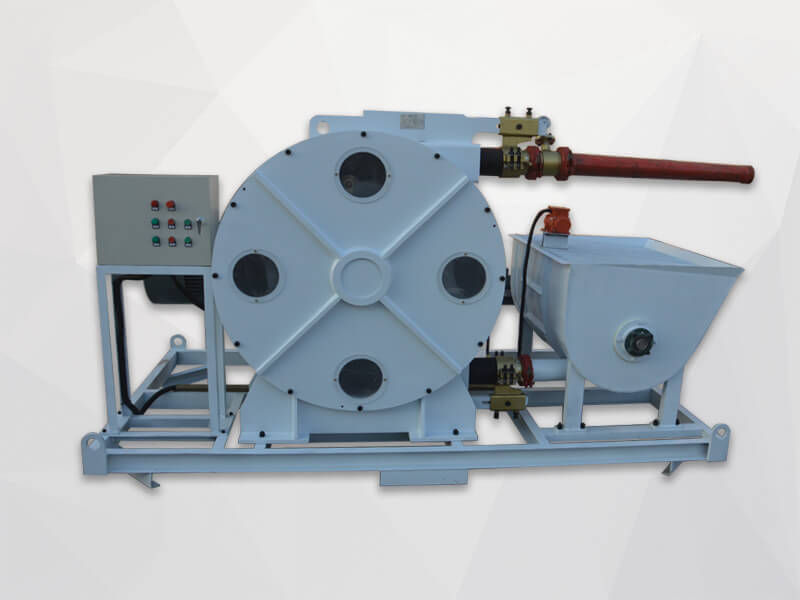

Equipped with a high-power motor, the dry floor screeding machine delivers continuous and strong power, ensuring a stable flow rate and pressure for mortar and other building materials during conveying. Combined with a large-capacity mixing tank, it not only provides ample material storage space but also achieves efficient mixing, guaranteeing mortar uniformity and construction quality. This perfect combination of power and capacity allows the LPXT400-E to handle the demands of large-scale, high-intensity construction operations easily.

The LPXT400-E Dry floor-screed conveyor features both horizontal and vertical bidirectional conveying capabilities, flexibly adapting to different construction site layouts and operational requirements. Whether in confined indoor spaces or on the exterior facades of high-rise buildings, the machine can achieve precise material delivery by adjusting the conveying angle and path, greatly improving construction flexibility and efficiency.

This model electric pneumatic conveyor for floor screeds supports an external air source as an auxiliary power source. This design not only enhances the stability of the delivery pressure but also allows the equipment to adjust the power configuration according to actual working conditions flexibly. The synergistic effect of the external air source and the powerful internal mixing function ensures that the mortar maintains a smooth delivery state throughout the entire working range, effectively avoiding common construction problems such as pipe blockage and segregation.

Equipped with a high-power motor, the dry floor screeding machine delivers continuous and strong power, ensuring a stable flow rate and pressure for mortar and other building materials during conveying. Combined with a large-capacity mixing tank, it not only provides ample material storage space but also achieves efficient mixing, guaranteeing mortar uniformity and construction quality. This perfect combination of power and capacity allows the LPXT400-E to handle the demands of large-scale, high-intensity construction operations easily.

The LPXT400-E Dry floor-screed conveyor features both horizontal and vertical bidirectional conveying capabilities, flexibly adapting to different construction site layouts and operational requirements. Whether in confined indoor spaces or on the exterior facades of high-rise buildings, the machine can achieve precise material delivery by adjusting the conveying angle and path, greatly improving construction flexibility and efficiency.

This model electric pneumatic conveyor for floor screeds supports an external air source as an auxiliary power source. This design not only enhances the stability of the delivery pressure but also allows the equipment to adjust the power configuration according to actual working conditions flexibly. The synergistic effect of the external air source and the powerful internal mixing function ensures that the mortar maintains a smooth delivery state throughout the entire working range, effectively avoiding common construction problems such as pipe blockage and segregation.

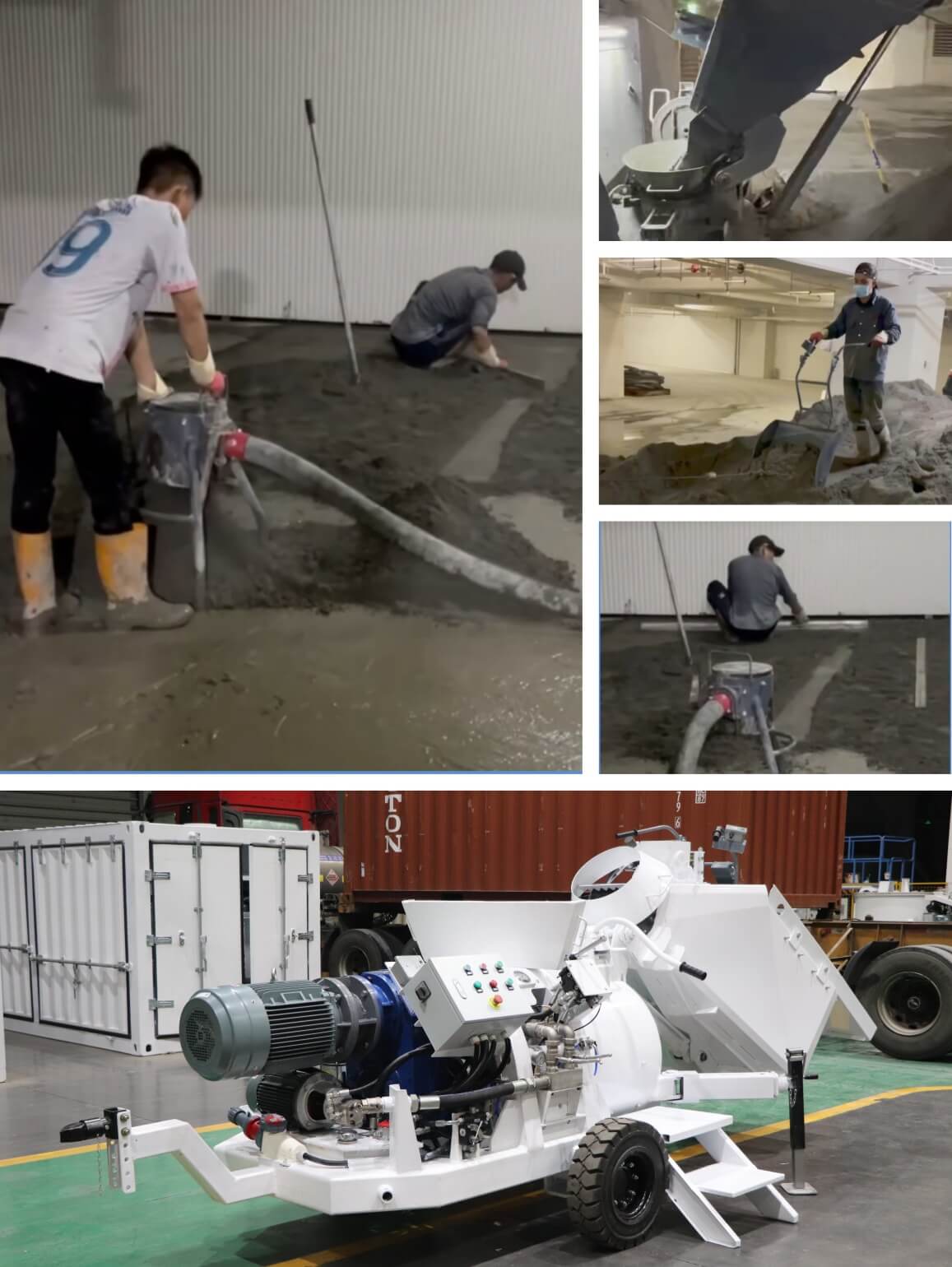

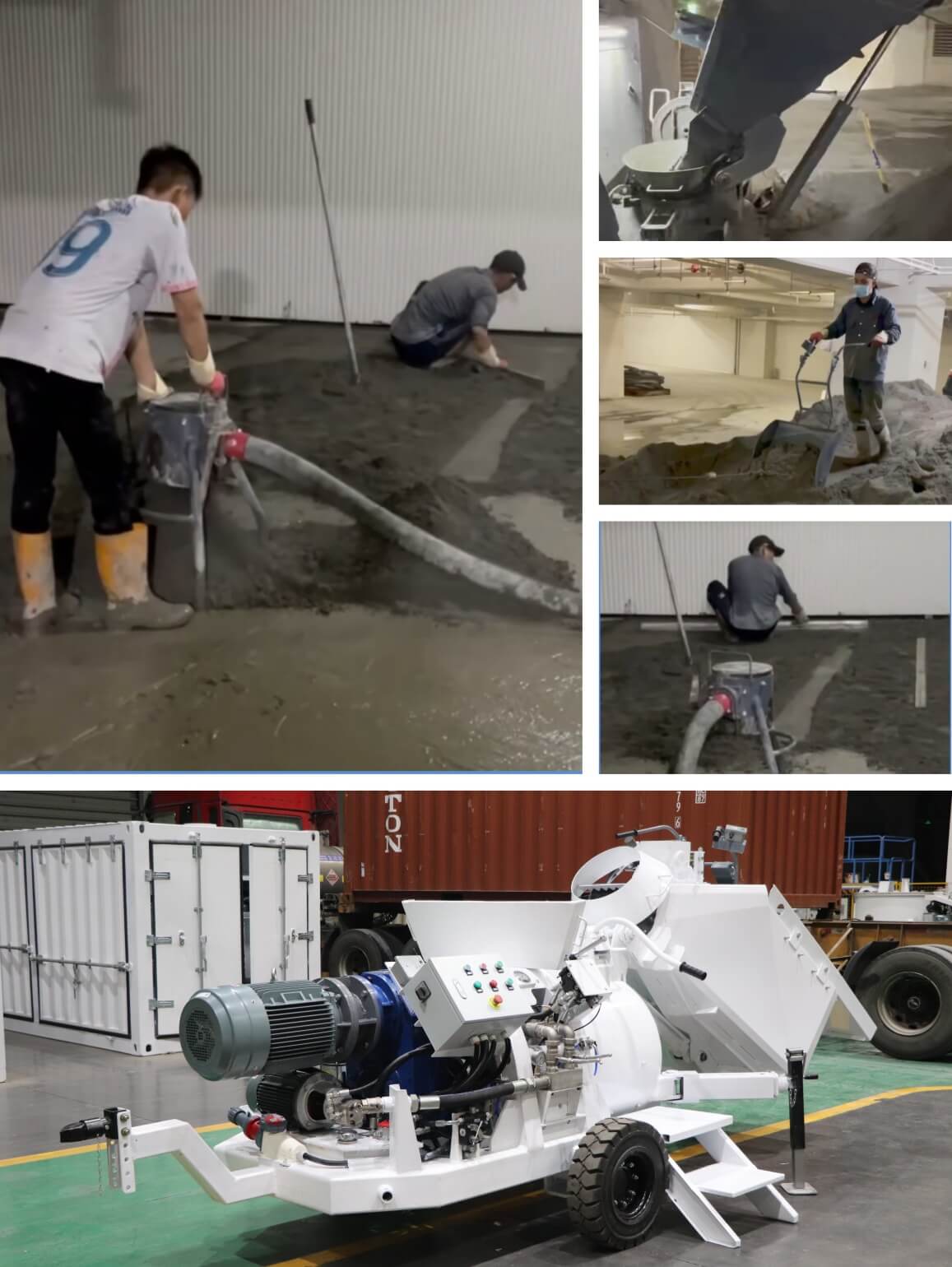

Application

LPXT400-E electric pneumatic conveyor for floor screeds application scenarios:

Dry Floor Screed Conveying Machine Core Application Areas:

1. Indoor Floor Leveling

Residential Buildings: Cement mortar leveling construction for indoor floors of high-rise residential buildings and apartments

Commercial Buildings: Base treatment for floors of large public buildings such as shopping malls, office buildings, and hotels

Industrial Plants: Workshops, warehouses, and other industrial sites with high requirements for floor flatness

2. Exterior Wall Insulation System Construction

Application of exterior wall insulation bonding mortar

Conveying and spraying of exterior wall plastering mortar

Treatment of exterior wall joints in prefabricated buildings

3. Underfloor Heating Backfill

Pouring of backfill layer after water-based underfloor heating system construction

Laying of mortar for electric underfloor heating protective layer

Efficient construction of large-area underfloor heating backfill

4. Roof Waterproofing Project

Roof leveling layer mortar construction

Base treatment before waterproofing layer

Laying of insulation mortar

Dry Floor Screed Conveyor Special Construction Scenarios:

1. 1. High-Rise Building Construction:

Utilizing the vertical conveying capacity of equipment, mortar is directly delivered to the high-rise work surface, reducing manual handling and labor intensity, and improving construction efficiency and shortening the construction period.

2. Construction in Confined Spaces:

Mortar construction in confined areas such as basements and garages; indoor leveling work in the renovation of old residential areas; flexible delivery hoses can extend to hard-to-reach work points.

3. Large-Area Continuous Operations:

Overall leveling of large warehouse floors; continuous paving of parking lot floors; large-area floor construction in industrial plants.

4. Irregular Structure Treatment

Mortar Application for Curved Walls and Surfaces

Material Filling for Complex Building Nodes

Mortar Repair for Special Building Parts

Applicable Material Types:

Dry-Mixed Mortar: Ordinary Dry-Mixed Mortar, Special Mortar

Cement-Based Materials: Cement Mortar, Self-Leveling Mortar

Insulation Mortar: Polystyrene Particle Insulation Mortar, Vitrified Microsphere Insulation Mortar

Bonding Materials: Tile Adhesive, Stone Adhesive, etc.

Summary of LPXT400-E Dry Floor Screeding Machine Application Advantages:

The table shows specific advantages that improve construction efficiency by 3-5 times compared to manual labor, shortening the construction period. Quality Control: Uniform mixing, stable conveying, ensuring construction quality. Cost Savings: Reduced labor costs, reduced material waste. Labor Intensity: Reduced heavy-duty handling, improved construction conditions. High Flexibility: Adaptable to various construction scenarios, with horizontal and vertical bidirectional conveying.

The LPXT400-E dry floor screeding machine, with its excellent conveying capacity and mixing performance, has been widely used in various construction projects and is an indispensable high-efficiency device for modern construction.

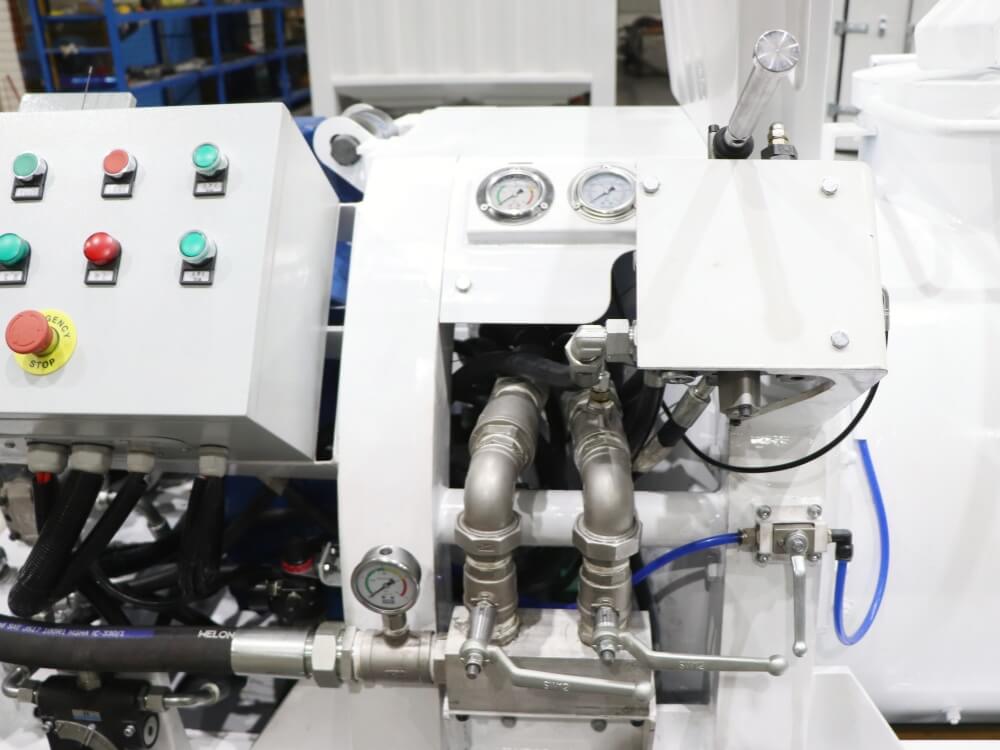

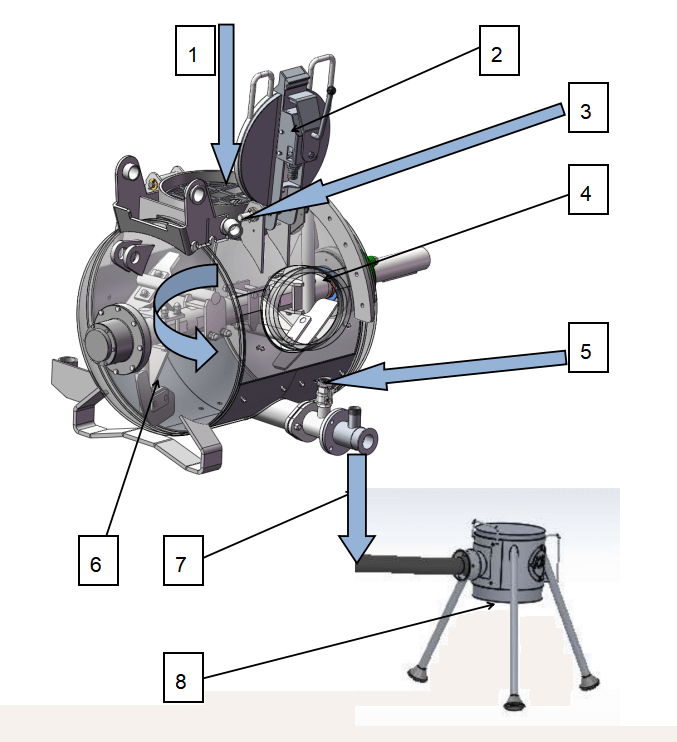

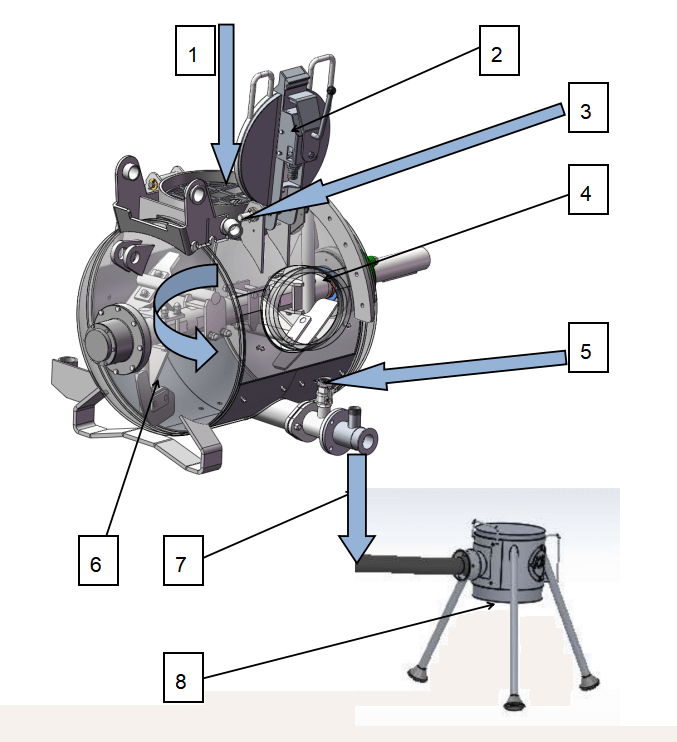

LPXT400-E Dry floor-screed conveying machine standard operating procedure:

Step 1: Adding Materials

Add the required materials (such as dry mortar, cement, etc.) into the mixing tank (No. 6). Ensure accurate weighing according to the formula ratio.

Step 2: Sealing the Tank

Place the sealing cap (No. 2) on top of the mixing tank and press it firmly to ensure a tight seal. This step is crucial for subsequent pneumatic conveying.

Step 3: Starting the Mixing System

Start the mixing system. The materials will begin to mix thoroughly in the mixing tank (6). The mixing shaft (4) will continue to rotate to ensure a uniform mixture. The mixing time should be adjusted according to the material characteristics and construction requirements.

Step 4: Starting Pneumatic Conveying

Once the materials are evenly mixed, introduce compressed air with sufficient pressure into the mixing tank (6) through the upper pipe (3) and lower pipe (5). Under air pressure, the materials will begin to be conveyed through the pipeline system.

Step 5: Material Discharge

The material is discharged from the discharge port (7), transported to the designated construction location via the conveying hose, and finally the construction operation is carried out from the terminal discharge port (8).

Dry Floor Screed Conveying Machine Core Application Areas:

1. Indoor Floor Leveling

Residential Buildings: Cement mortar leveling construction for indoor floors of high-rise residential buildings and apartments

Commercial Buildings: Base treatment for floors of large public buildings such as shopping malls, office buildings, and hotels

Industrial Plants: Workshops, warehouses, and other industrial sites with high requirements for floor flatness

2. Exterior Wall Insulation System Construction

Application of exterior wall insulation bonding mortar

Conveying and spraying of exterior wall plastering mortar

Treatment of exterior wall joints in prefabricated buildings

3. Underfloor Heating Backfill

Pouring of backfill layer after water-based underfloor heating system construction

Laying of mortar for electric underfloor heating protective layer

Efficient construction of large-area underfloor heating backfill

4. Roof Waterproofing Project

Roof leveling layer mortar construction

Base treatment before waterproofing layer

Laying of insulation mortar

Dry Floor Screed Conveyor Special Construction Scenarios:

1. 1. High-Rise Building Construction:

Utilizing the vertical conveying capacity of equipment, mortar is directly delivered to the high-rise work surface, reducing manual handling and labor intensity, and improving construction efficiency and shortening the construction period.

2. Construction in Confined Spaces:

Mortar construction in confined areas such as basements and garages; indoor leveling work in the renovation of old residential areas; flexible delivery hoses can extend to hard-to-reach work points.

3. Large-Area Continuous Operations:

Overall leveling of large warehouse floors; continuous paving of parking lot floors; large-area floor construction in industrial plants.

4. Irregular Structure Treatment

Mortar Application for Curved Walls and Surfaces

Material Filling for Complex Building Nodes

Mortar Repair for Special Building Parts

Applicable Material Types:

Dry-Mixed Mortar: Ordinary Dry-Mixed Mortar, Special Mortar

Cement-Based Materials: Cement Mortar, Self-Leveling Mortar

Insulation Mortar: Polystyrene Particle Insulation Mortar, Vitrified Microsphere Insulation Mortar

Bonding Materials: Tile Adhesive, Stone Adhesive, etc.

Summary of LPXT400-E Dry Floor Screeding Machine Application Advantages:

The table shows specific advantages that improve construction efficiency by 3-5 times compared to manual labor, shortening the construction period. Quality Control: Uniform mixing, stable conveying, ensuring construction quality. Cost Savings: Reduced labor costs, reduced material waste. Labor Intensity: Reduced heavy-duty handling, improved construction conditions. High Flexibility: Adaptable to various construction scenarios, with horizontal and vertical bidirectional conveying.

The LPXT400-E dry floor screeding machine, with its excellent conveying capacity and mixing performance, has been widely used in various construction projects and is an indispensable high-efficiency device for modern construction.

LPXT400-E Dry floor-screed conveying machine standard operating procedure:

Step 1: Adding Materials

Add the required materials (such as dry mortar, cement, etc.) into the mixing tank (No. 6). Ensure accurate weighing according to the formula ratio.

Step 2: Sealing the Tank

Place the sealing cap (No. 2) on top of the mixing tank and press it firmly to ensure a tight seal. This step is crucial for subsequent pneumatic conveying.

Step 3: Starting the Mixing System

Start the mixing system. The materials will begin to mix thoroughly in the mixing tank (6). The mixing shaft (4) will continue to rotate to ensure a uniform mixture. The mixing time should be adjusted according to the material characteristics and construction requirements.

Step 4: Starting Pneumatic Conveying

Once the materials are evenly mixed, introduce compressed air with sufficient pressure into the mixing tank (6) through the upper pipe (3) and lower pipe (5). Under air pressure, the materials will begin to be conveyed through the pipeline system.

Step 5: Material Discharge

The material is discharged from the discharge port (7), transported to the designated construction location via the conveying hose, and finally the construction operation is carried out from the terminal discharge port (8).

Features

LPXT400-E Dry floor-screed conveying machine technical configuration details:

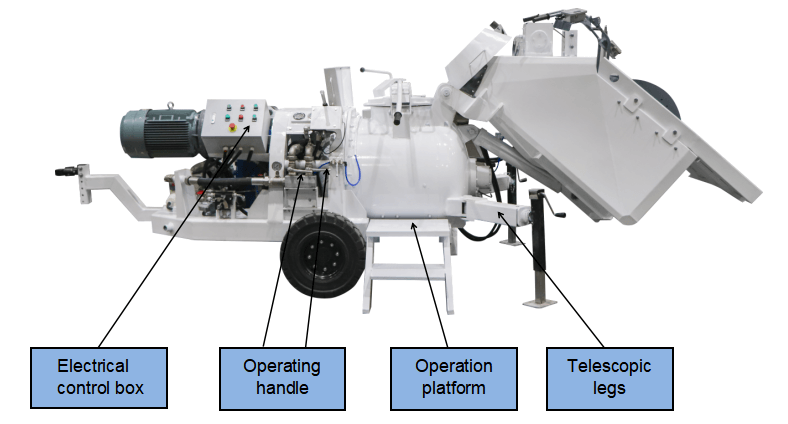

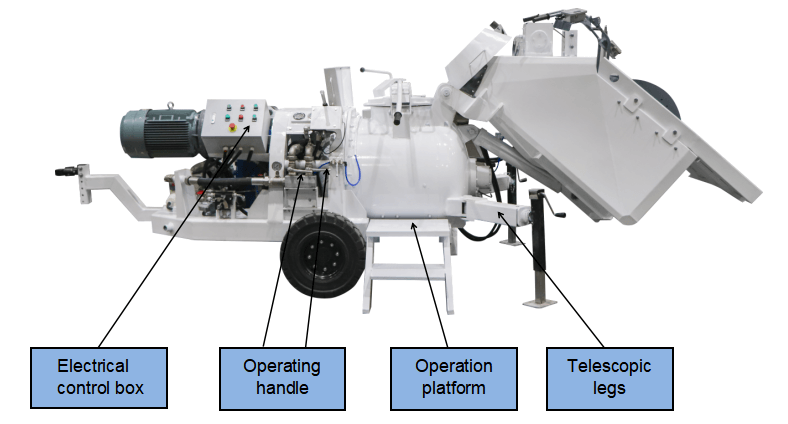

1. Mobility and Support System

Mobile Trailer Chassis

Flexible Mobility: Equipped with a professional trailer chassis, enabling free movement of the equipment on the construction site.

Site Adaptability: No external hoisting equipment required; quick positioning via towing.

Convenient Transportation: The entire machine can be towed for easy relocation between different construction sites.

High-Load-Bearing Solid Tires

Robust and Durable: Utilizes a high-load-bearing solid tire design, requiring no inflation maintenance.

Site Adaptability: Can operate stably in harsh ground conditions such as gravel and mud.

High Load Capacity: Ensures safe movement and operational stability under full load.

High-Load-Bearing Adjustable Jack Support Legs

Stable Support: Equipped with high-strength jack support legs, providing stable support during operation.

Height Adjustable: Flexible adjustment of support height according to ground conditions to ensure equipment level.

Safety Guarantee: Prevents equipment swaying during operation, improving construction safety.

Rapid Deployment: Hydraulic/mechanical lifting operation for rapid support erection.

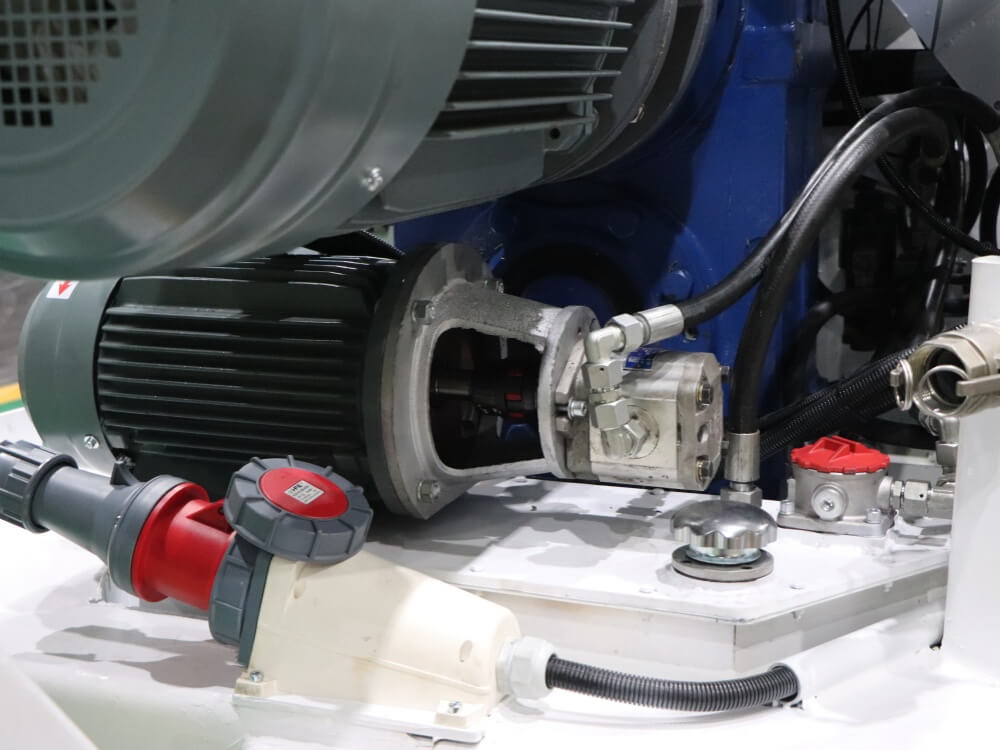

2. Core Power System

22KW Mixing Motor

Powerful Performance: 22kW high-power motor provides ample mixing torque

Efficient Mixing: Ensures thorough and uniform mixing of various mortar materials

Continuous Operation: Supports long-term continuous operation, meeting the needs of high-intensity construction

Energy-Saving Design: Optimized motor efficiency reduces energy costs

4KW Hydraulic Pump Motor

Hydraulic Drive: Provides stable power output for the hydraulic system

Precise Control: Enables smooth operation of the hydraulic feeding device

Rapid Response: Quickly responds to operating commands, improving work efficiency

Reliable and Durable: High-quality hydraulic components extend equipment lifespan

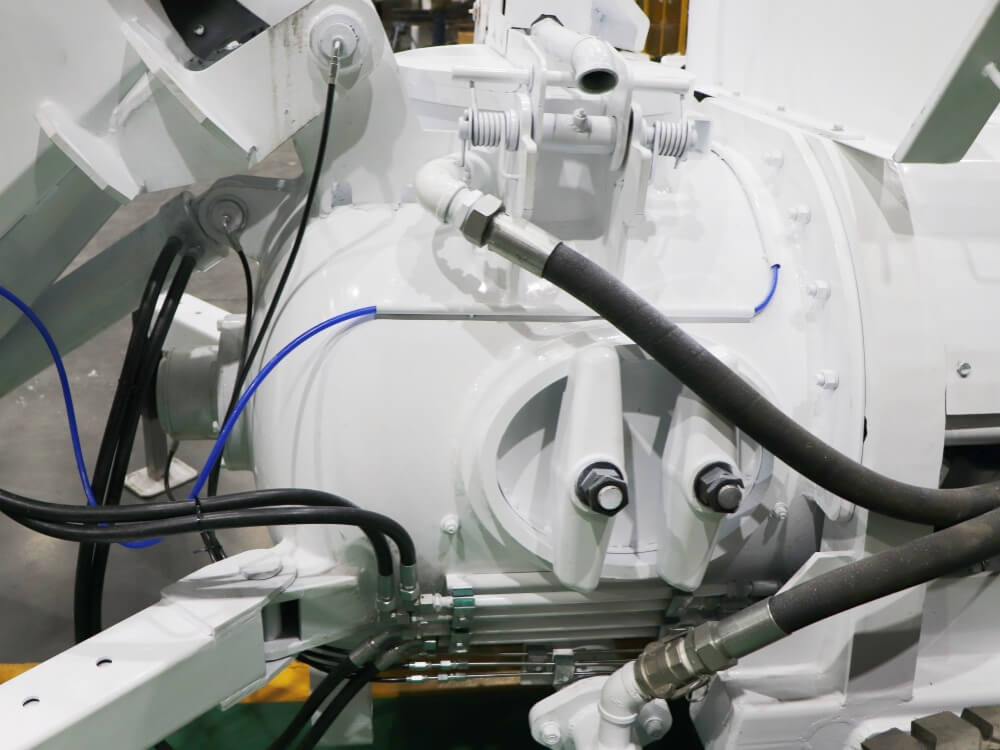

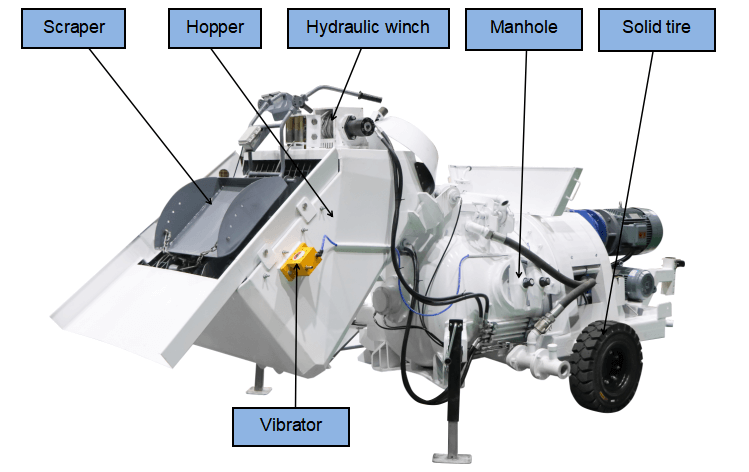

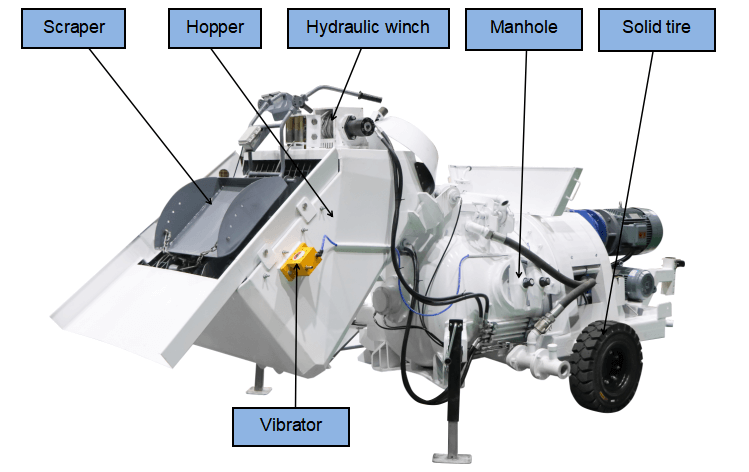

3. Hydraulic Feeding Device

Hydraulic Driven Feeding System

Easy Feeding: Hydraulically driven automatic feeding device significantly reduces manual labor intensity

Continuous Feeding: Enables continuous and stable material conveying, improving work efficiency

Easy Operation: Hydraulic control is simple and easy to learn, lowering the operating threshold

Precise Control: Feeding speed and quantity can be precisely adjusted, avoiding material waste

4. Wear-resistant and Protective Design

Replaceable Wear-resistant Liners

Easy Maintenance: The mixing tank's inner wall features replaceable wear-resistant liners.

Extended Lifespan: Protects the tank from wear, extending the overall lifespan of the equipment.

Reduced Costs: Liners can be replaced individually, eliminating the need for complete tank replacement.

Superior Material: Utilizes high-hardness wear-resistant materials, resistant to long-term friction and impact.

4 Wear-resistant Mixing Blades

Highly Efficient Mixing: Four carefully designed mixing blades create a powerful vortex mixing effect.

Uniform Mixing: The synergistic action of multiple blades ensures thorough mixing of materials.

High Durability: Blades are made of wear-resistant material, resistant to damage even after long-term use.

Easy Replacement: Modular design allows for quick replacement of damaged blades.

With these superior technical features, the LPXT400-E dry floor screeding machine achieves efficient, stable, and durable operating performance, making it an ideal choice for modern construction sites.

1. Mobility and Support System

Mobile Trailer Chassis

Flexible Mobility: Equipped with a professional trailer chassis, enabling free movement of the equipment on the construction site.

Site Adaptability: No external hoisting equipment required; quick positioning via towing.

Convenient Transportation: The entire machine can be towed for easy relocation between different construction sites.

High-Load-Bearing Solid Tires

Robust and Durable: Utilizes a high-load-bearing solid tire design, requiring no inflation maintenance.

Site Adaptability: Can operate stably in harsh ground conditions such as gravel and mud.

High Load Capacity: Ensures safe movement and operational stability under full load.

High-Load-Bearing Adjustable Jack Support Legs

Stable Support: Equipped with high-strength jack support legs, providing stable support during operation.

Height Adjustable: Flexible adjustment of support height according to ground conditions to ensure equipment level.

Safety Guarantee: Prevents equipment swaying during operation, improving construction safety.

Rapid Deployment: Hydraulic/mechanical lifting operation for rapid support erection.

2. Core Power System

22KW Mixing Motor

Powerful Performance: 22kW high-power motor provides ample mixing torque

Efficient Mixing: Ensures thorough and uniform mixing of various mortar materials

Continuous Operation: Supports long-term continuous operation, meeting the needs of high-intensity construction

Energy-Saving Design: Optimized motor efficiency reduces energy costs

4KW Hydraulic Pump Motor

Hydraulic Drive: Provides stable power output for the hydraulic system

Precise Control: Enables smooth operation of the hydraulic feeding device

Rapid Response: Quickly responds to operating commands, improving work efficiency

Reliable and Durable: High-quality hydraulic components extend equipment lifespan

3. Hydraulic Feeding Device

Hydraulic Driven Feeding System

Easy Feeding: Hydraulically driven automatic feeding device significantly reduces manual labor intensity

Continuous Feeding: Enables continuous and stable material conveying, improving work efficiency

Easy Operation: Hydraulic control is simple and easy to learn, lowering the operating threshold

Precise Control: Feeding speed and quantity can be precisely adjusted, avoiding material waste

4. Wear-resistant and Protective Design

Replaceable Wear-resistant Liners

Easy Maintenance: The mixing tank's inner wall features replaceable wear-resistant liners.

Extended Lifespan: Protects the tank from wear, extending the overall lifespan of the equipment.

Reduced Costs: Liners can be replaced individually, eliminating the need for complete tank replacement.

Superior Material: Utilizes high-hardness wear-resistant materials, resistant to long-term friction and impact.

4 Wear-resistant Mixing Blades

Highly Efficient Mixing: Four carefully designed mixing blades create a powerful vortex mixing effect.

Uniform Mixing: The synergistic action of multiple blades ensures thorough mixing of materials.

High Durability: Blades are made of wear-resistant material, resistant to damage even after long-term use.

Easy Replacement: Modular design allows for quick replacement of damaged blades.

With these superior technical features, the LPXT400-E dry floor screeding machine achieves efficient, stable, and durable operating performance, making it an ideal choice for modern construction sites.

Product Details

Technical Parameters

Technical Data

| Model | LPXT400-E Dry floor-screed conveying machine |

| Mixing Motor | 22KW |

| Hydraulic Pump Motor | 4KW |

| Operating Voltage | 380V, 50HZ |

| Vessel Capacity | Gross 520L / Net 400L |

| Output Capacity | 9m³/h |

| Operation Pressure | 2bar~8bar |

| Air Consumption | 4~8m3/min |

| Lubrication System | Central Automatic |

| Chassis Tow Connection | Ball Coupling |

| Dimension L×W×H | 4840×1700×1650mm |

| Weight | 2595kg |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LPXT200-D/A Floor screed conveyor is a specialized floor screed conveyor engineered to streamline the mixing and transportation of screed materials on construction sites.LPXT200-D/A Floor screed conveyor

LPXT200-D/A Floor screed conveyor is a specialized floor screed conveyor engineered to streamline the mixing and transportation of screed materials on construction sites.LPXT200-D/A Floor screed conveyor -

LPXT200-D/A Screed machine-Mortar Mixer And Transfer Machine With Air Pressure is designed to deliver smooth, reliable power to convey the type of construction material continuously.LPXT200-D/A Screed machine-Mortar Mixer And Transfer Machine With Air Pressure

LPXT200-D/A Screed machine-Mortar Mixer And Transfer Machine With Air Pressure is designed to deliver smooth, reliable power to convey the type of construction material continuously.LPXT200-D/A Screed machine-Mortar Mixer And Transfer Machine With Air Pressure -

LMP-5X Screw type mortar grout mixer pump represents a high-efficiency technological innovation. It is designed for large-area plastering applications, including plastering mortar, thermal insulation mortar, and thick layers of mortar. Additionally, it finds extensive use in construction for various mortar types such as masonry mortar, reinforced mortar, filling mortar, perfusion mortar, fiber mortar, and self-leveling mortar. This machine is a versatile solution for a range of plastering needs.LMP-5X Screw type mortar grout mixer pump

LMP-5X Screw type mortar grout mixer pump represents a high-efficiency technological innovation. It is designed for large-area plastering applications, including plastering mortar, thermal insulation mortar, and thick layers of mortar. Additionally, it finds extensive use in construction for various mortar types such as masonry mortar, reinforced mortar, filling mortar, perfusion mortar, fiber mortar, and self-leveling mortar. This machine is a versatile solution for a range of plastering needs.LMP-5X Screw type mortar grout mixer pump -

LMP70/30 double piston plastering machine can handle aggregates with a particle size up to a maximum of 5 mm, ensuring high efficiency, low maintenance costs, and low energy consumption.LMP70/30 Double Piston Plastering Machine

LMP70/30 double piston plastering machine can handle aggregates with a particle size up to a maximum of 5 mm, ensuring high efficiency, low maintenance costs, and low energy consumption.LMP70/30 Double Piston Plastering Machine

.jpg)

.jpg)