High presse jet grouting pump 600-800 bar

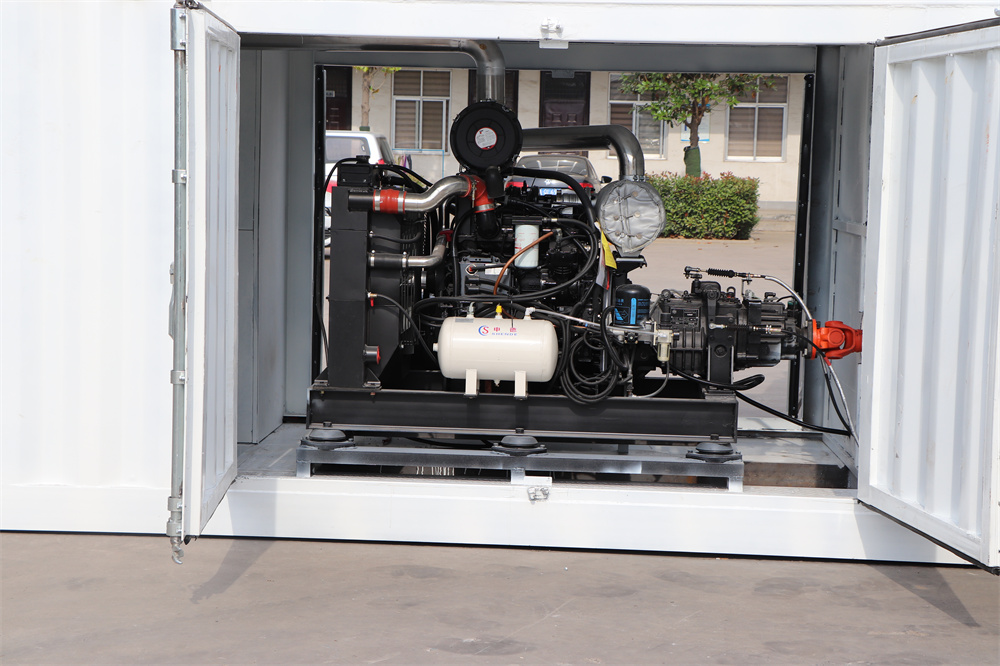

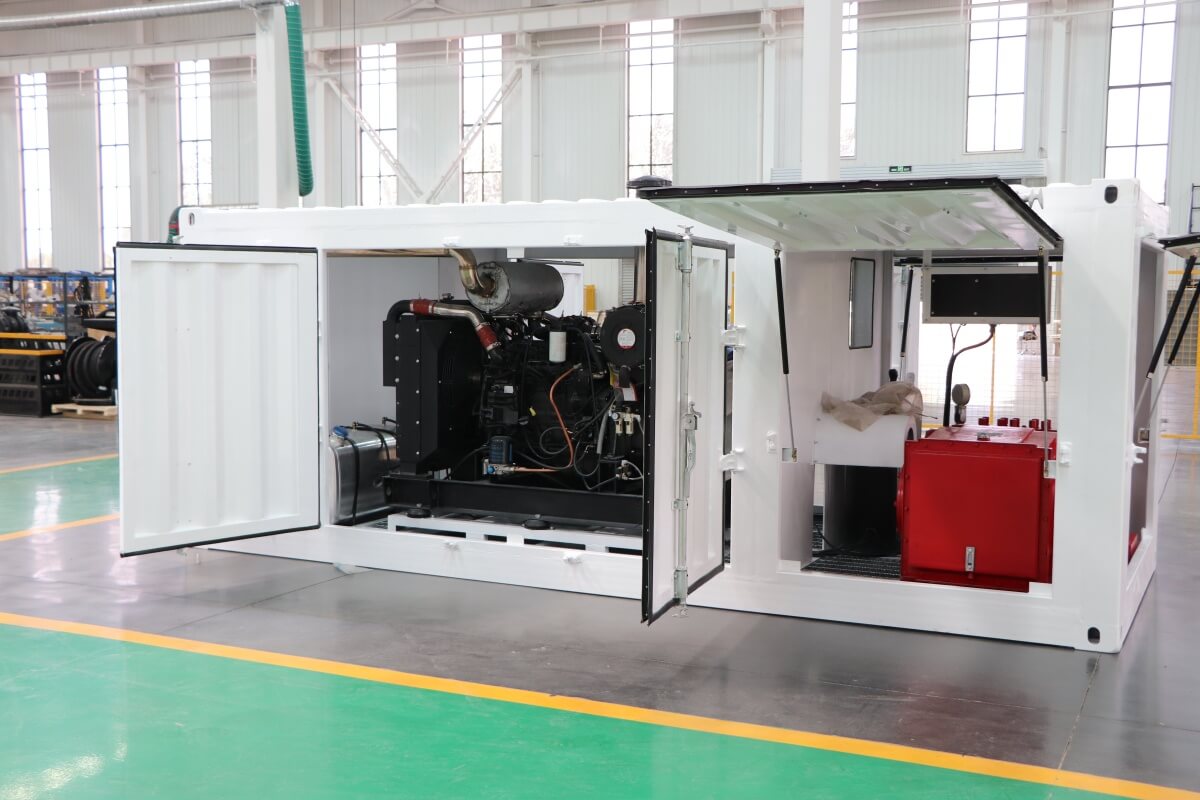

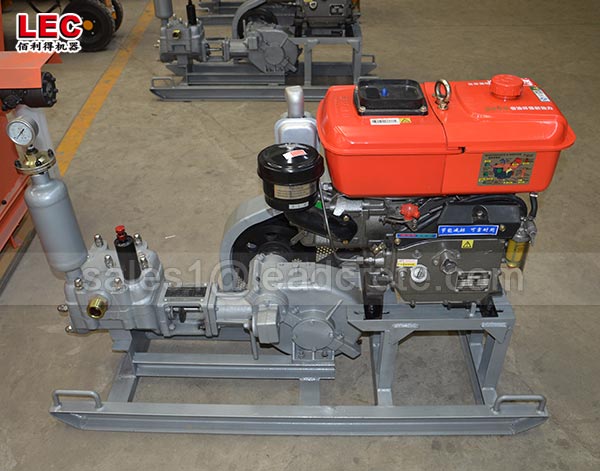

The working pressure of 600-800 bar enables the High press jet grouting pump to penetrate deeper rock and soil layers, achieving effective grouting reinforcement. According to engineering needs, the flow rate of the grouting pump can be adjusted to meet the requirements of different grouting processes. The design of modern high-pressure jet grouting pumps emphasizes the compactness of the structure, making it easy to transport and install. The High press jet grouting pump 600-800 bar adopts an advanced control system, making the operation of the grouting pump more convenient and efficient.

Deep foundation treatment: In the construction of high-rise buildings, bridges, roads and other infrastructure, the stability of the foundation is the primary consideration. High pressure jet grouting pump can inject high-pressure slurry into deep foundation, effectively reinforcing the foundation, improving bearing capacity and stability.

Tunnels and underground engineering: Grouting reinforcement is an important means to ensure construction safety and quality in underground engineering such as tunnel excavation, subway construction, and underground pipe galleries. A high-pressure injection grouting pump with a pressure range of 600-800 bar can ensure that the slurry penetrates deep into the rock and soil mass under high pressure, forming an effective reinforcement layer.

Slope and retaining wall reinforcement: In slope engineering in mountainous and hilly areas, as well as in retaining wall reinforcement projects in cities, the application of high-pressure jet grouting pumps can significantly enhance the overall integrity and stability of rock and soil, and prevent geological disasters such as landslides and collapses.

High pressure jet grouting pumps also play an important role in the anti-seepage and reinforcement treatment of water conservancy projects such as reservoir dams, embankments, and water gates. Continuous anti-seepage curtains or reinforcement layers are formed through high-pressure grouting to ensure the safe operation of water conservancy projects.

Construction under special geological conditions: When construction is carried out in karst areas, goaf and other special geological conditions, high-pressure jet grouting pumps can provide necessary grouting reinforcement methods to ensure construction safety and engineering quality.