Your position:

Home > Products > Grout Pump

LGP250/450-250D High pressure jet grouting pump

Working principle of high pressure jet grouting pump is to inject high pressure fluid (usually cement slurry) into the ground through a nozzle, eroding and mixing the in-situ soil and cement slurry to form a solidified body called a soil-cement column or slab. This process is usually called jet grouting.

LGP250/450-250D

Reciprocating single acting plunger type

3piece

Φ75mm

250L/min @ 450bar

64 mm

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

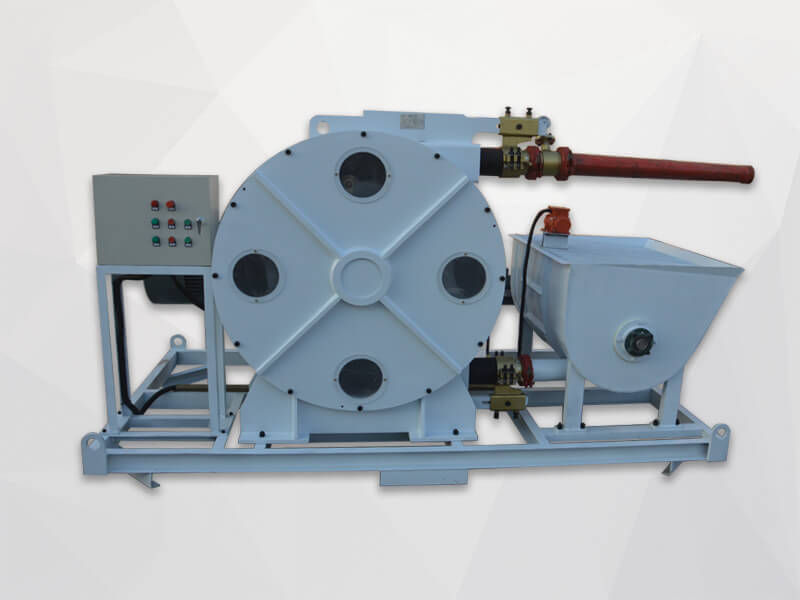

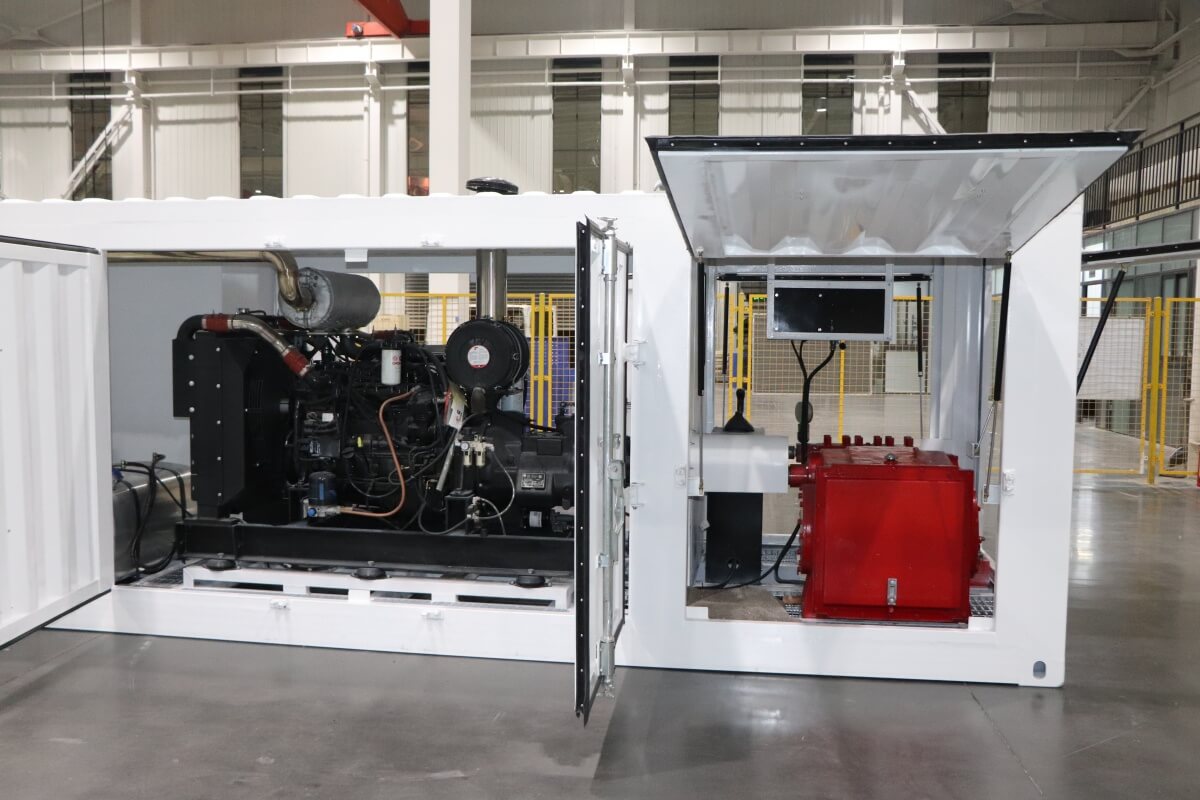

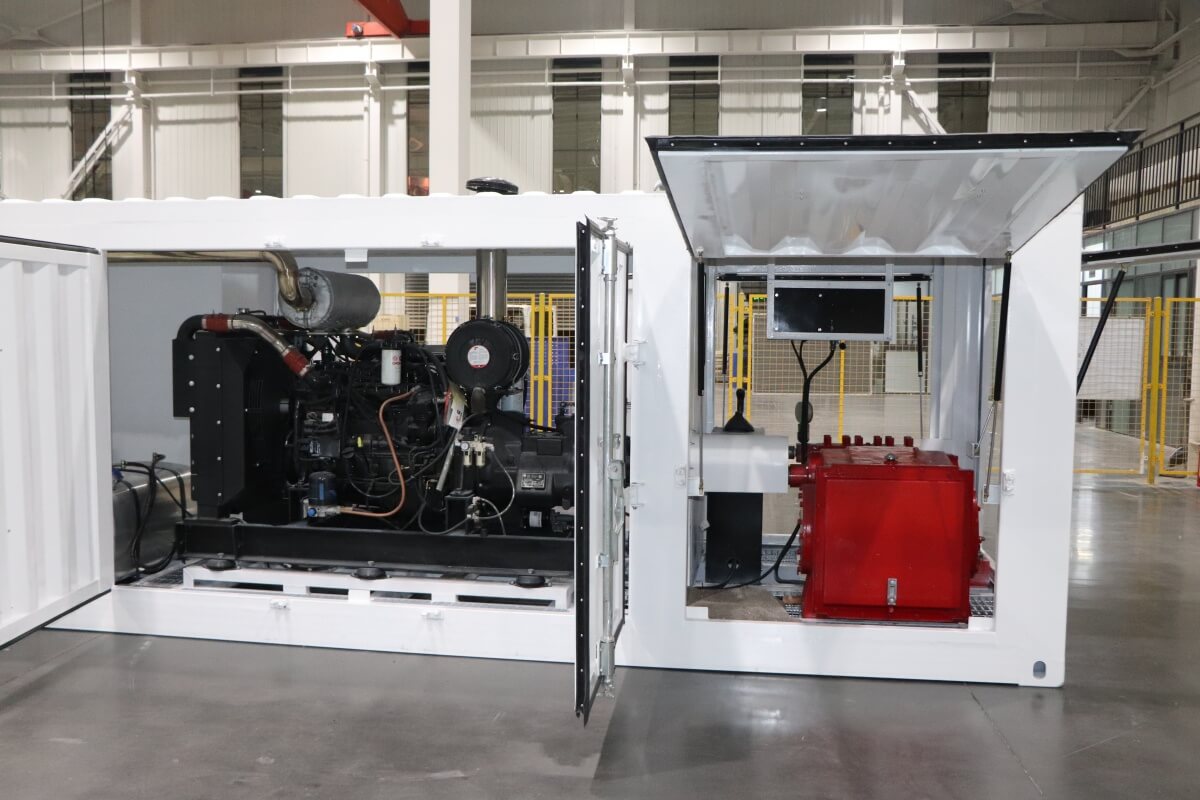

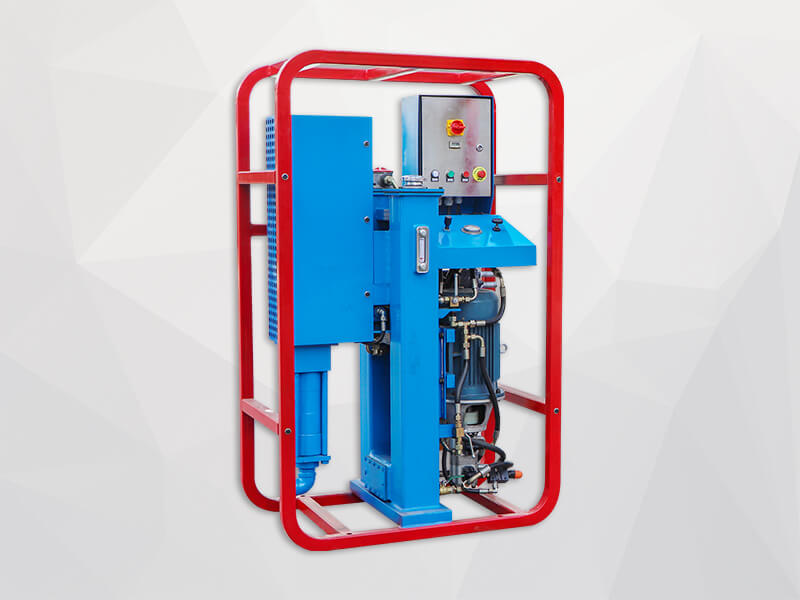

LGP250/450-250D High pressure jet grouting pump stands out as a sophisticated piece of machinery, specifically engineered as a horizontal three cylinder single action reciprocating pump. Our company, drawing inspiration from the cutting edge structural designs of foreign plunger pumps, has meticulously crafted this pump to meet the highest industry standards.

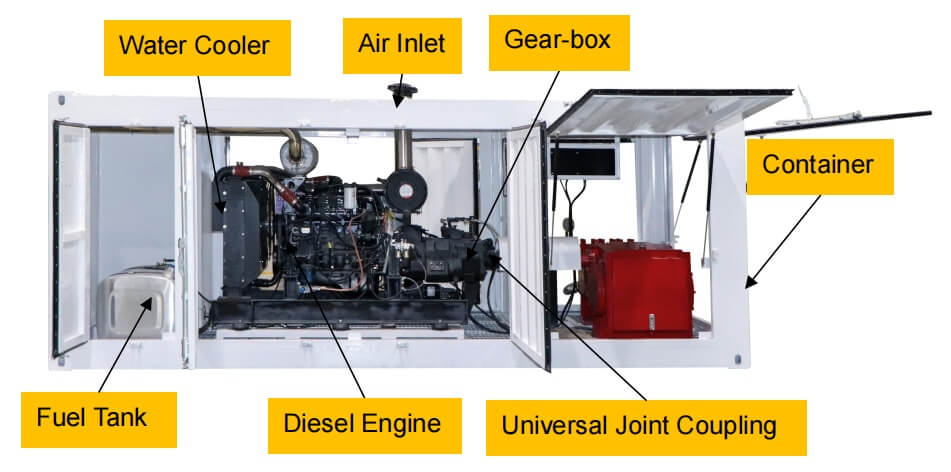

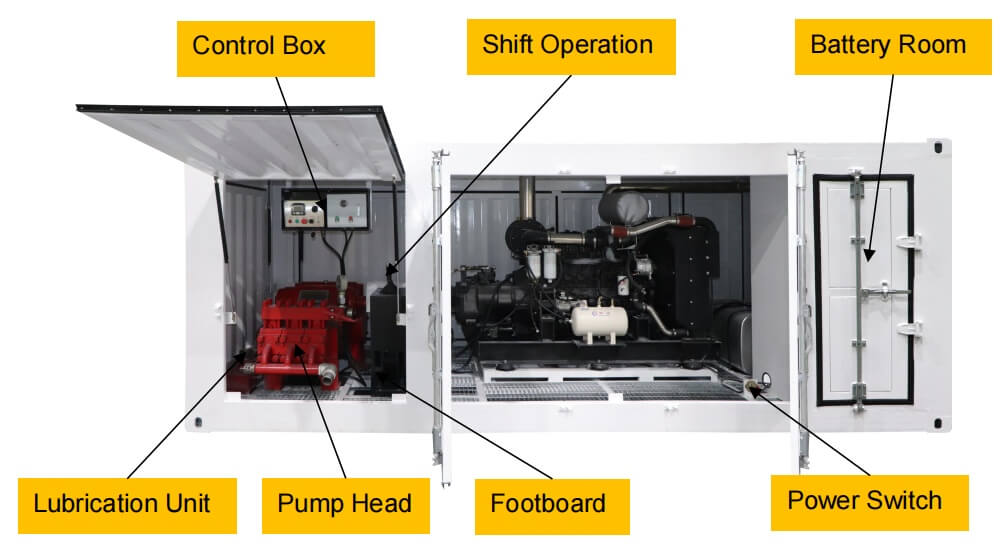

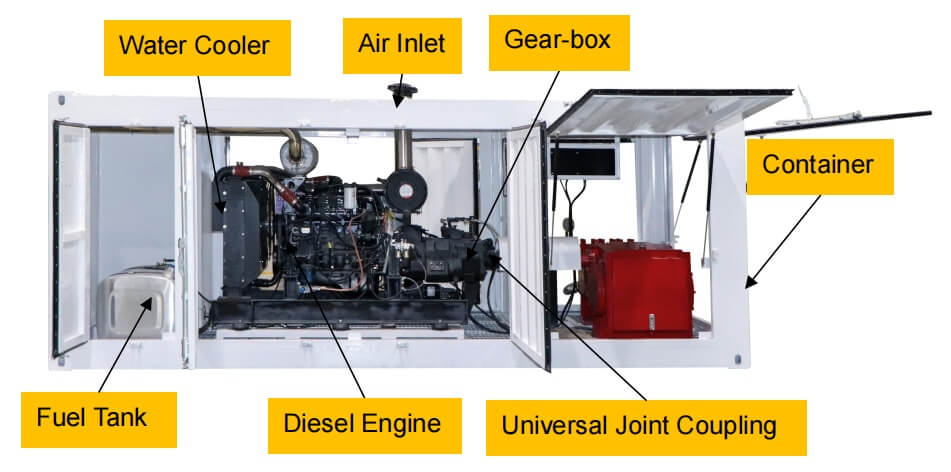

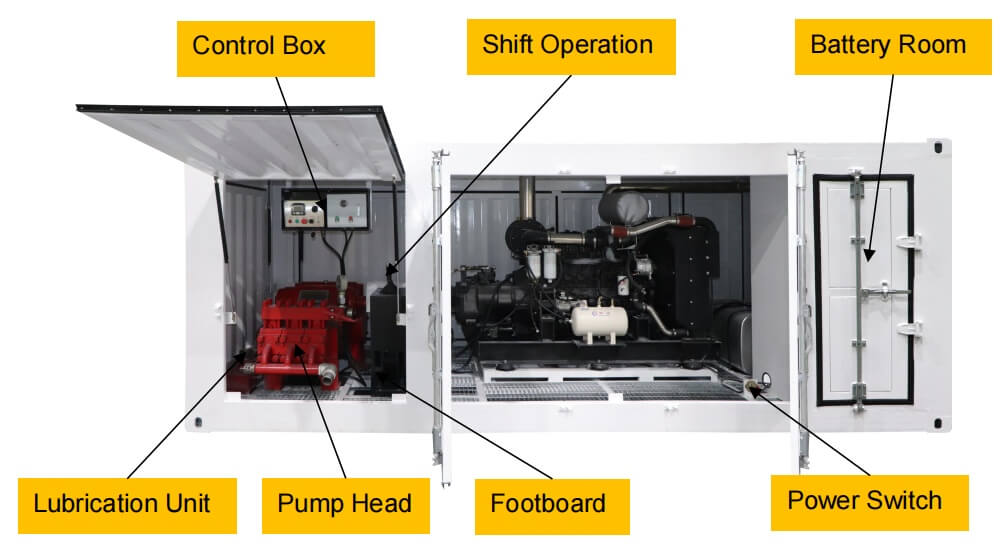

This high pressure triplex jet grout pump is a well - integrated system, comprising several key components. At its core is the power end, which is a robust 260HP diesel engine. This QSF6.7-260C Cummins serves as the heart of the jet grout pump, providing the necessary power to drive the entire system. Connected to the power end is a clutch, which allows for smooth engagement and disengagement of power transmission.

The gear box, manufactured by the renowned Eaton FAST, is another crucial part. It features four gears and offers the advantage of being continuously variable according to specific operational requirements. This flexibility enables the jet grout pump to adapt to different working conditions, ensuring optimal performance. In addition to the gear box, a universal joint coupling is incorporated into the design, facilitating efficient power transfer between the various components.

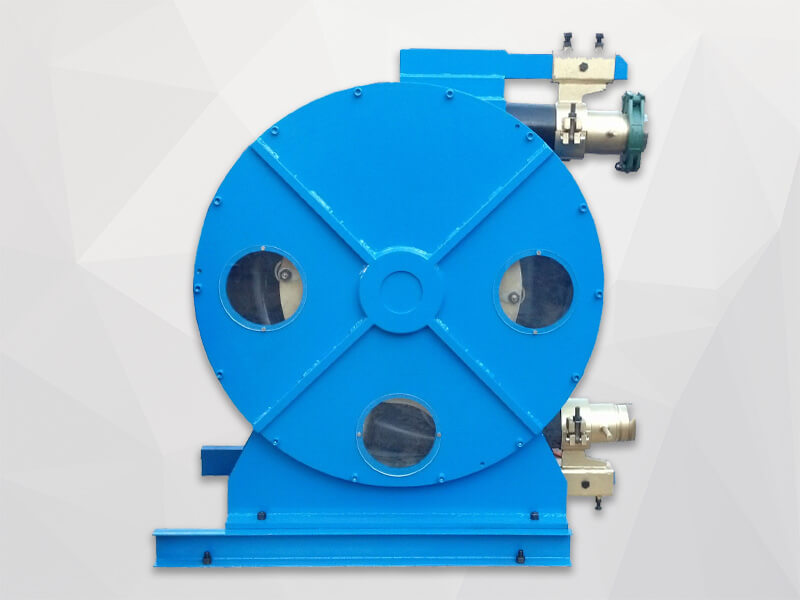

One of the standout features of the LGP250/450-250D is its high pressure pump section. Unlike traditional domestic products that often utilize needle roller transmission, which is susceptible to damage, this high pressure grout pump adopts a tile type transmission. This innovative design change brings about significant benefits. While there is normal wear and tear between the tiles and the shaft, it does not lead to sudden, catastrophic failures that can halt a project. As a result, the working life of the pump's power end is greatly extended, reducing maintenance costs and downtime.

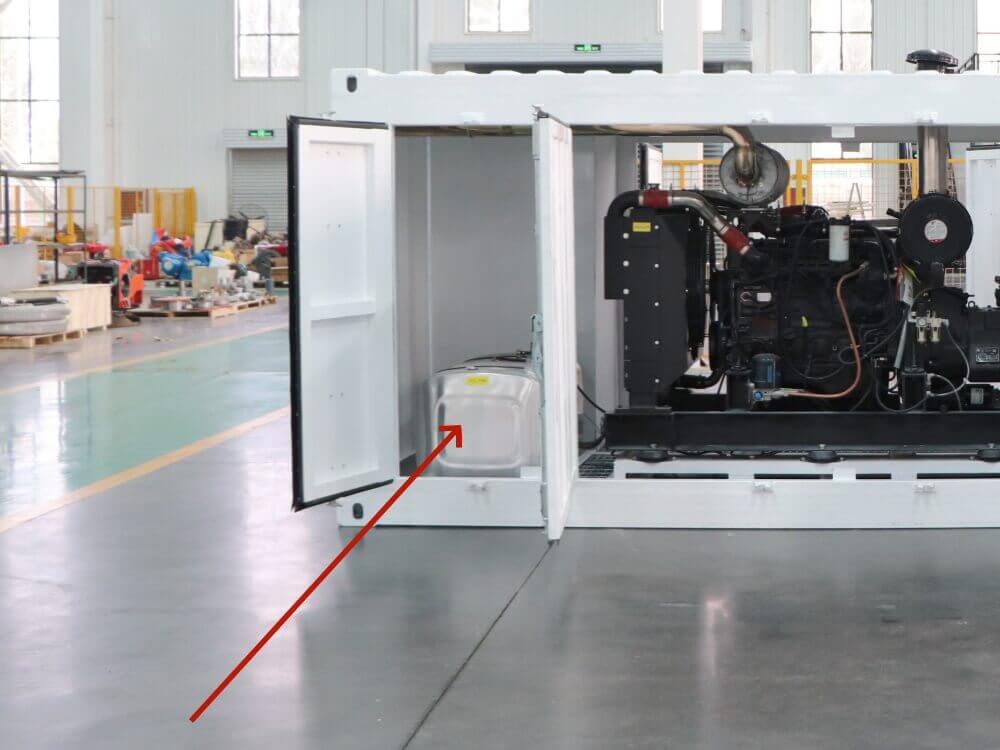

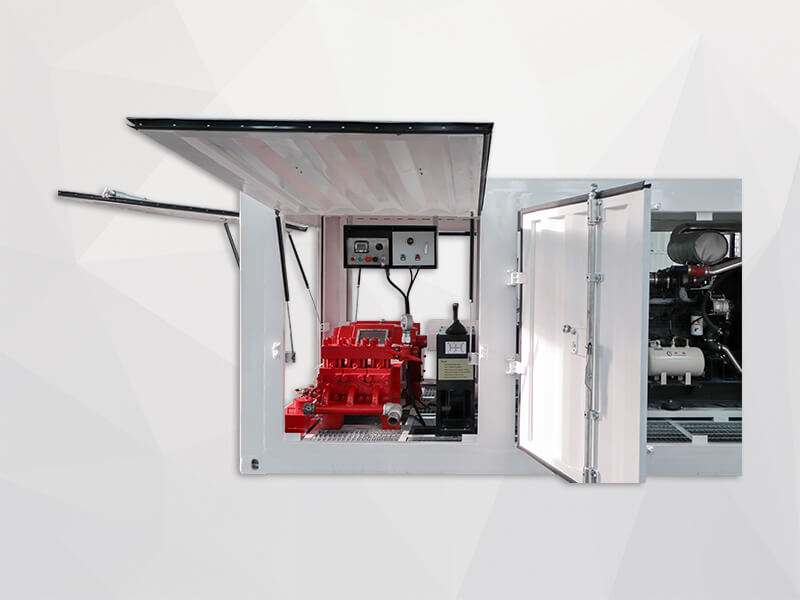

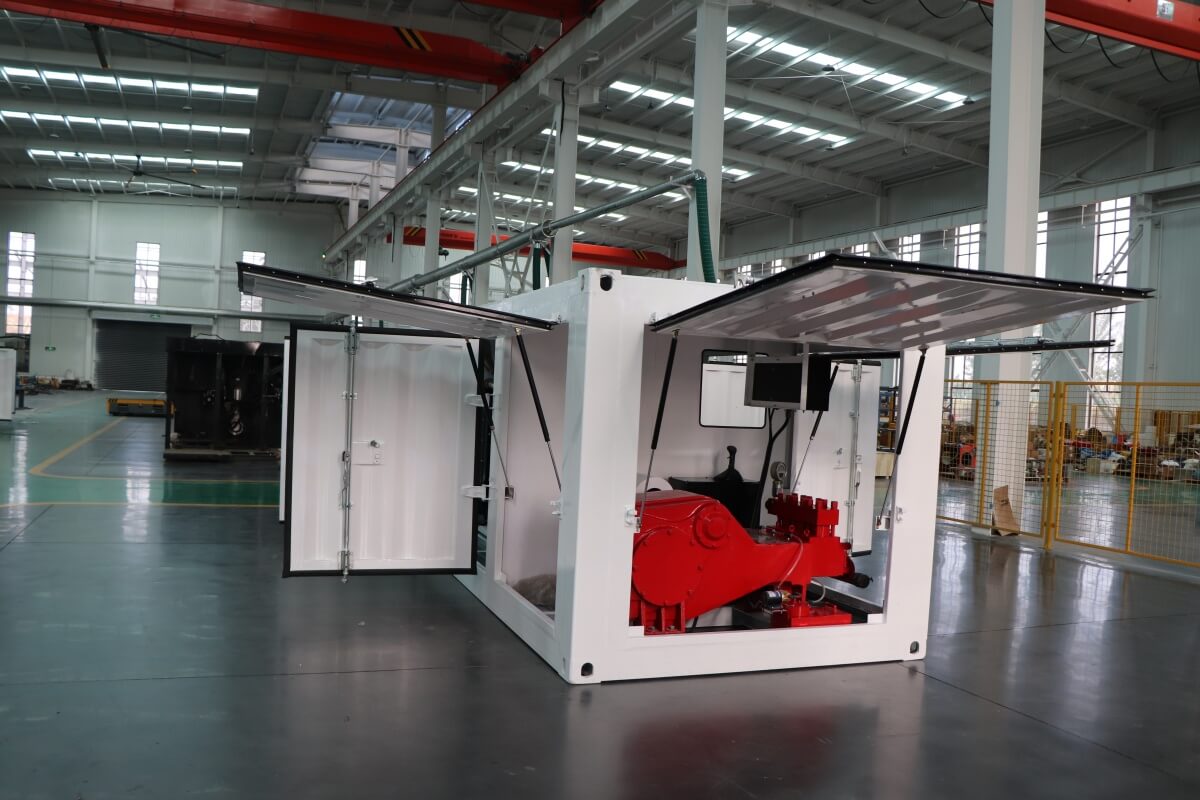

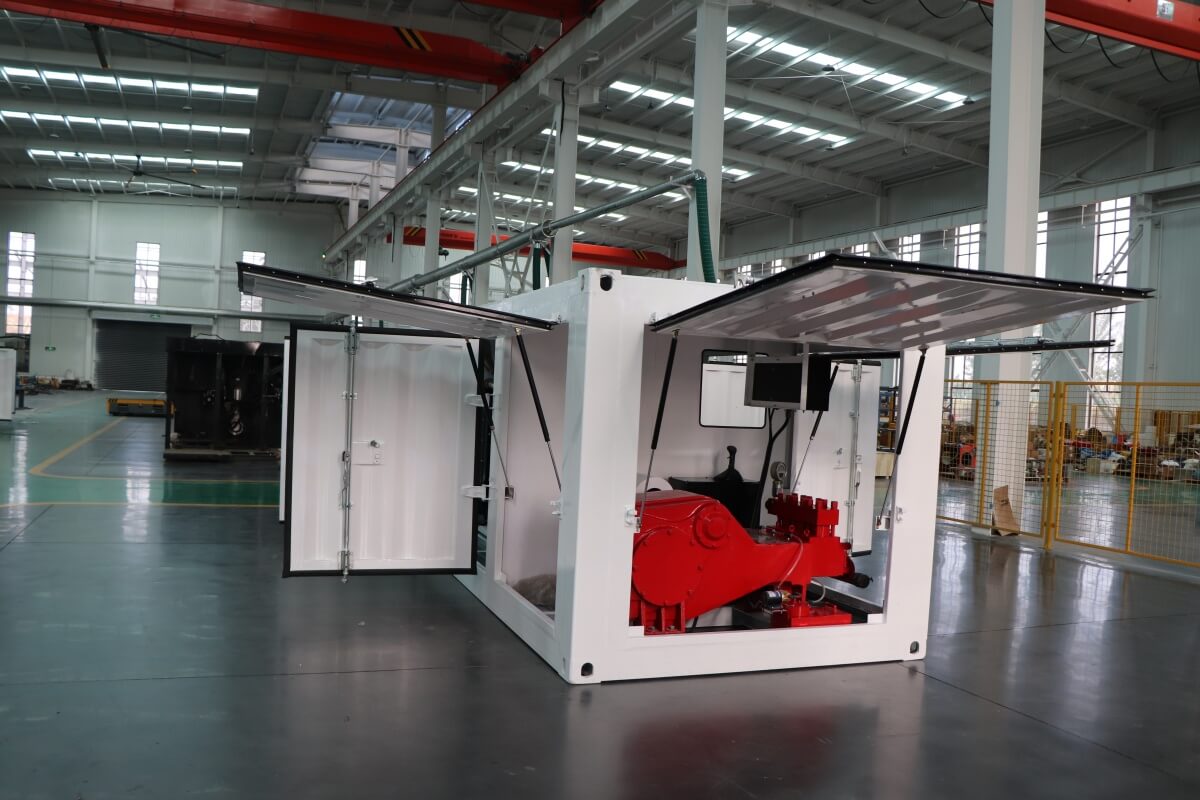

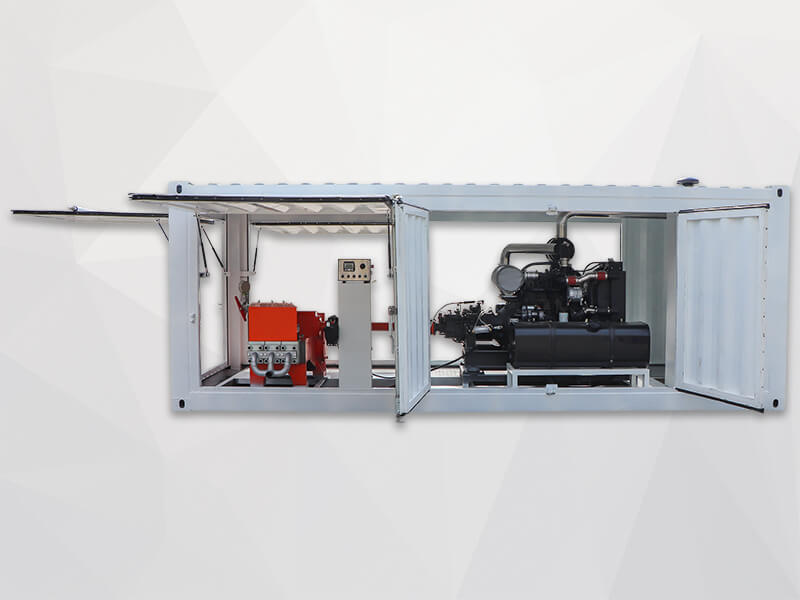

From a logistical perspective, the LGP250/450-250D diesel driven high pressure jet grouting pump offers great convenience. It can be easily placed inside a 20ft container, which simplifies transportation. This makes it possible to quickly deploy the pump to different project sites, whether they are located in remote areas or urban centers.

This high pressure triplex jet grout pump is a well - integrated system, comprising several key components. At its core is the power end, which is a robust 260HP diesel engine. This QSF6.7-260C Cummins serves as the heart of the jet grout pump, providing the necessary power to drive the entire system. Connected to the power end is a clutch, which allows for smooth engagement and disengagement of power transmission.

The gear box, manufactured by the renowned Eaton FAST, is another crucial part. It features four gears and offers the advantage of being continuously variable according to specific operational requirements. This flexibility enables the jet grout pump to adapt to different working conditions, ensuring optimal performance. In addition to the gear box, a universal joint coupling is incorporated into the design, facilitating efficient power transfer between the various components.

One of the standout features of the LGP250/450-250D is its high pressure pump section. Unlike traditional domestic products that often utilize needle roller transmission, which is susceptible to damage, this high pressure grout pump adopts a tile type transmission. This innovative design change brings about significant benefits. While there is normal wear and tear between the tiles and the shaft, it does not lead to sudden, catastrophic failures that can halt a project. As a result, the working life of the pump's power end is greatly extended, reducing maintenance costs and downtime.

From a logistical perspective, the LGP250/450-250D diesel driven high pressure jet grouting pump offers great convenience. It can be easily placed inside a 20ft container, which simplifies transportation. This makes it possible to quickly deploy the pump to different project sites, whether they are located in remote areas or urban centers.

Application

The applications of the LGP250/450-250D high pressure diesel driven jet grouting pump are diverse and far reaching. In the field of construction, it plays a vital role in strengthening weak foundations. Whether it's for new buildings, highways, high - speed railways, or underground railways, this pump provides the high pressure power needed to ensure the stability and durability of these structures. For old buildings suffering from uneven settlement, the high pressure jet injection pump can be used for treatment, helping to restore their structural integrity.

In geotechnical engineering, it is used for creating deep prevention curtains and soil retaining cofferdams. These structures are essential for preventing soil erosion and ensuring the safety of adjacent areas during construction projects. In the mining industry, the pump is used for mine leakage prevention, well barrel protection arms, and slope anchoring, contributing to the safe and efficient extraction of minerals.

In reservoir dams and underground construction projects, the pump's capabilities are also highly valued. It can be used for high pressure water harvesting, which assists in rock breaking and coal falling, making the mining process more efficient. Additionally, it provides hydraulic props for underground hydraulic supply, ensuring the stability of underground workings. Anchoring operations, such as the use of hydraulic expansion metal anchor rods, also rely on the pump to pump high - pressure water.

Moreover, the high pressure jet grouting system has applications in the maintenance of large underground pipelines. It can be used for dredging and cleaning, ensuring the smooth flow of fluids through these pipelines. In the field of rock and soil excavation, it can create perforations using high pressure water jets, making it easier to break through tough materials.

In geotechnical engineering, it is used for creating deep prevention curtains and soil retaining cofferdams. These structures are essential for preventing soil erosion and ensuring the safety of adjacent areas during construction projects. In the mining industry, the pump is used for mine leakage prevention, well barrel protection arms, and slope anchoring, contributing to the safe and efficient extraction of minerals.

In reservoir dams and underground construction projects, the pump's capabilities are also highly valued. It can be used for high pressure water harvesting, which assists in rock breaking and coal falling, making the mining process more efficient. Additionally, it provides hydraulic props for underground hydraulic supply, ensuring the stability of underground workings. Anchoring operations, such as the use of hydraulic expansion metal anchor rods, also rely on the pump to pump high - pressure water.

Moreover, the high pressure jet grouting system has applications in the maintenance of large underground pipelines. It can be used for dredging and cleaning, ensuring the smooth flow of fluids through these pipelines. In the field of rock and soil excavation, it can create perforations using high pressure water jets, making it easier to break through tough materials.

Features

1. Dynamical system: (high Factor of safety and efficiency)

260HP Cummins diesel engine, high efficiency, more suitable for the construction site

Low voltage operation, safer

2. Transmission system (wide speed range, high transmission efficiency):

Implementing a 4-speed continuously variable transmission with Fast transmission, a wide speed range, and high transmission efficiency

Using a retractable universal joint coupling to compensate for various irregularities caused by rotation

The use of tile transmission extends the service life of the pump power end

Grouting pressure(up to 450bar) and displacement(up to 250L/min) can be adjusted steplessly

3. Plunger type jet triplex grout pump

3-cylinder plunger, diameter 75mm, stroke 100mm

3-cylinder alternating motion ensures stability of pressure and flow

Using special steel quenching treatment

The pump head is forged from a complete section

4. Operating system

Convenience, high degree of automation, simple measurement and operation

5. Diaphragm valve

When the inlet pressure reaches the opening pressure, the diaphragm is sheared and the pressure is released, resulting in high safety

6. Container(L×W×H 5700×2280×2190mm):

Structure with reference to the standard container

Anti-slip step steel grid plates are used in empty places

Can be placed directly in the 20ft cabinet

7. Easy to operate and maintain

8. Equipped with some ceiling lamps for illuminating the different working areas

260HP Cummins diesel engine, high efficiency, more suitable for the construction site

Low voltage operation, safer

2. Transmission system (wide speed range, high transmission efficiency):

Implementing a 4-speed continuously variable transmission with Fast transmission, a wide speed range, and high transmission efficiency

Using a retractable universal joint coupling to compensate for various irregularities caused by rotation

The use of tile transmission extends the service life of the pump power end

Grouting pressure(up to 450bar) and displacement(up to 250L/min) can be adjusted steplessly

3. Plunger type jet triplex grout pump

3-cylinder plunger, diameter 75mm, stroke 100mm

3-cylinder alternating motion ensures stability of pressure and flow

Using special steel quenching treatment

The pump head is forged from a complete section

4. Operating system

Convenience, high degree of automation, simple measurement and operation

5. Diaphragm valve

When the inlet pressure reaches the opening pressure, the diaphragm is sheared and the pressure is released, resulting in high safety

6. Container(L×W×H 5700×2280×2190mm):

Structure with reference to the standard container

Anti-slip step steel grid plates are used in empty places

Can be placed directly in the 20ft cabinet

7. Easy to operate and maintain

8. Equipped with some ceiling lamps for illuminating the different working areas

Product Details

Technical Parameters

Technical Data

| Model | LGP250/450-250D High pressure grout pump for jet grouting | ||

| Diesel engine |

Type | QSF6.7-260C Cummins | |

| Power | HP | 260 | |

| Max. speed | r/min | 2200 | |

| Gear-box |

Type | EATON FASE | |

| Speed | 4 | ||

| Control | Level | ||

| Main jet grout pump |

Type | GP250/450 | |

| Form of action | Reciprocating single acting plunger type | ||

| Number of Plungers | Piece | 3 | |

| Plungers | mm | Φ75 | |

| Output @ Pressure | L/min@bar | 250@450 | |

| Inlet diameter | mm | 64 | |

| Outlet diameter | mm | 32 | |

| Note: 1. All data are tested by water. 2. We can customize products according to your requirements. |

|||

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

High pressure grout injection pump for drilling rig is crucial in various construction and geotechnical applications, such as stabilizing soil, filling voids, or strengthening foundations.LGP440/50PI-22E High pressure grout injection pump for drilling rig

High pressure grout injection pump for drilling rig is crucial in various construction and geotechnical applications, such as stabilizing soil, filling voids, or strengthening foundations.LGP440/50PI-22E High pressure grout injection pump for drilling rig -

Diesel driven jet grouting pump in 20ft container provides high-pressure power for various construction projects, including strengthening weak foundations in new buildings, highways, high-speed railways, and underground railways.LGP114/500-120D Diesel driven jet grouting pump in 20ft container

Diesel driven jet grouting pump in 20ft container provides high-pressure power for various construction projects, including strengthening weak foundations in new buildings, highways, high-speed railways, and underground railways.LGP114/500-120D Diesel driven jet grouting pump in 20ft container -

LGM50/80PLD-E Double-Plunger hydraulic Grout Pump is designed with two low-wear plungers pump. With the features of double acting, ball valves, low pressure surge, variable pressure and flow. Therefore, this pump is suitable for all grouting work, up to 8mm particle size , such as, for the pumping of backfill mortar behind tunnel liners, grouting in soil, earth foundation stabilization, waterproofing, tunnel lining, underwater foundations, bridge decks, deep well casing, slope line grouting, etc.LGM80/50PLD-E Double plunger hydraulic grout pump

LGM50/80PLD-E Double-Plunger hydraulic Grout Pump is designed with two low-wear plungers pump. With the features of double acting, ball valves, low pressure surge, variable pressure and flow. Therefore, this pump is suitable for all grouting work, up to 8mm particle size , such as, for the pumping of backfill mortar behind tunnel liners, grouting in soil, earth foundation stabilization, waterproofing, tunnel lining, underwater foundations, bridge decks, deep well casing, slope line grouting, etc.LGM80/50PLD-E Double plunger hydraulic grout pump -

China injection vertical grout pump is designed and made for permeation grouting, compaction grouting, backfilling grouting, curtain grouting, high pressure split grouting etc., grouting methods.LDH75/100PI-E injection vertical grout pump

China injection vertical grout pump is designed and made for permeation grouting, compaction grouting, backfilling grouting, curtain grouting, high pressure split grouting etc., grouting methods.LDH75/100PI-E injection vertical grout pump

.jpg)

.jpg)