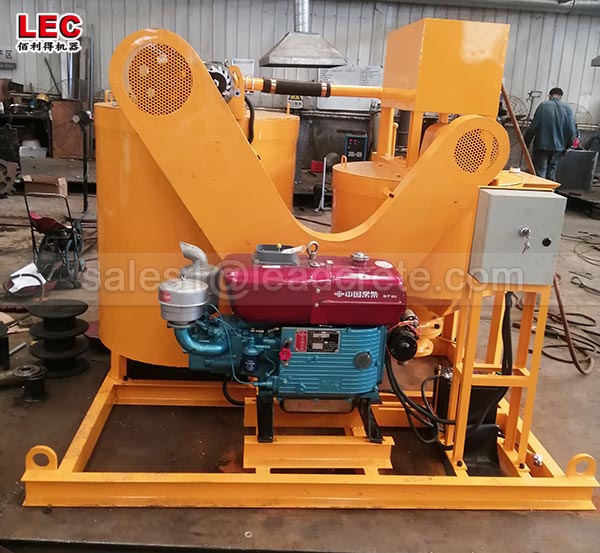

Bentonite cement grout mixer

A bentonite-cement grout mixer is a specialized piece of equipment designed to blend bentonite (a swelling clay), cement, water, and optional additives into a homogeneous, pumpable grout. This mixture is critical in applications requiring soil stabilization, waterproofing, or void filling, such as tunneling, mining, and geotechnical engineering.

Bentonite cement grout mixer is an industrial equipment designed to mix bentonite, cement, water and chemical additives, designed to produce uniform, pumpable grout materials. Its core functions include:

High-efficiency mixing: Disperse bentonite (high-water-absorbent clay) with cement to avoid agglomeration.

Precise proportions: Control the ratio of water, solids and additives through automated or manual systems.

Adapt to complex formulas: Supports the mixing of different bentonite types (such as sodium-based, calcium-based) and cement varieties (such as ordinary silicate cement, fast hard cement).

Continuous production: Some models support batch or continuous stirring to meet the needs of large-scale engineering.

Bentonite cement grout mixer applications:

1. Tunneling & Mining:

Annulus grouting behind tunnel linings.

Rock bolt and cable bolt sealing.

Water inflow control in underground excavations.

2. Geotechnical Engineering:

Soil stability (e.g., compaction grouting, jet grouting).

Slope stability and erosion control.

3. Civil Construction:

Dam and reserver sealing.

Foundation grouting for bridges and buildings.

Void filling under slabs or pipelines