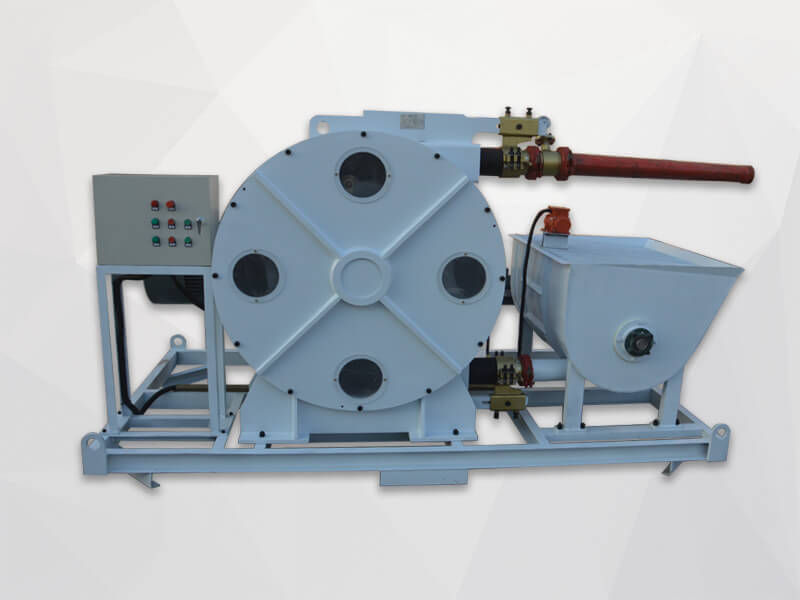

LGP220/300/300PI-E Customized high shear grout mixing plant is designed based on high speed vortex mixer and mortar mixer. It achieves continuous and high speed mortar mixing and grouting. High shear grout plant is mainly used in municipal, highway, railway, hydropower, construction, mining and other construction site for mortar grout. This customized grout injection plant is driven by electric motor, mechanical plunger type grout pump. LGP220/300/300PI-E mortar cement grout plant is suitable for making cement mixture and mortar cement mixture.

Working principle of LGP220/300/300PI-E mortar grout plant :

Evenly mixed slurry convey to No. 1 agitator. Add sand to No. 1 agitator and mix. Evenly mixed mortar cement mixture flows into No. 2 agitator through discharge outlet. Grouting pump sucks mixture from No. 2 agitator and finish the grouting, gunite and backfilling etc. project. Grouting, while the next round of mixing can be carried out, thus the grout station achieves continuous work.

High shear grout mixing plant has special mixing effect of cement or bentonite with water is archived in mixer by a high turbulence created in the pump casing. This turbulence with its high shear forces separates the cement or bentonite particles which results in a fully hydrated suspension.

As soon as the mixing process is over, the mixing is transferred into the agitator. The slow stirring paddle prevents the grout from settling out of suspension and removes any air bubbles from the mix. Each grout plant incorporates mixers and pumps of matched capacity which together with an agitated storage tank enable virtually continuous operation once work has commenced.

High shear grout mixing plant for mine application - roadway reinforcement, backfill, waterproof grouting.

Customized grout plant for civil engineering - dam, tunnel, subway, mine, soil nailing wall, curtain, anchor, cable trench and anchor grouting.

Customized grout unit for engineering - underwater foundation, offshore platform, coast foundation grouting reinforcement.

Customized grout station for building structure - building and bridge repair, foundation reinforcement, slope support, soil compaction, terrg grouting.

2. Less spare parts ensure low maintenance costs.

3. The motor has an overload protection function.

4. High speed vortex mixer ensures mix quickly and evenly.

5. High shear grout mixing plant has continuous output with small pulse.

6. Grouting pressure, output of customized grout plant is stepless adjustable.

7. Customized grout station is simple structure, light weight, easy maintenance.

8. Customized grout unit mixer and agitator switch by using squeeze handle, it is safe, reliable and easy to operate.

9. Customized grout injection plant has wrong operation safety protection device. When the vibrating screen mesh is taken up, the machine will stop.

10. Compact size, it is easy to operate and also takes small place.

11. Grout pump of LGP220/300/300PI-E mortar cement grout plant adopts frequency control, so the flow is step-less adjustable.

| Description | Data |

| customized grout injection plant model | LGP220/300/300PI-E |

| Dimensions | 2350x1830x1600mm |

| Weight | 1275kg |

| Mixer | |

| Capacity | 220L |

| Output | 4m3/h |

| Power | 5.5Kw, 1450rpm,50Hz,380V |

| Rated Rev. | 1450rpm |

| W/C | 0.5~1 |

| Cement/Sand | ≥1 |

| No.1 Agitator | |

| Capacity | 300L |

| Rated Rev. | 49rpm |

| Power | 1.5KW, 50Hz,380V |

| No.2 Agitator | |

| Capacity | 300L |

| Rated Rev. | 36rpm |

| Power | 1.5KW, 50Hz,380V |

| Pump | |

| Max. output | 50L/min |

| Max. pressure | 1.5MPa |

| Power | 4kw, 50Hz,380V |

-

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station -

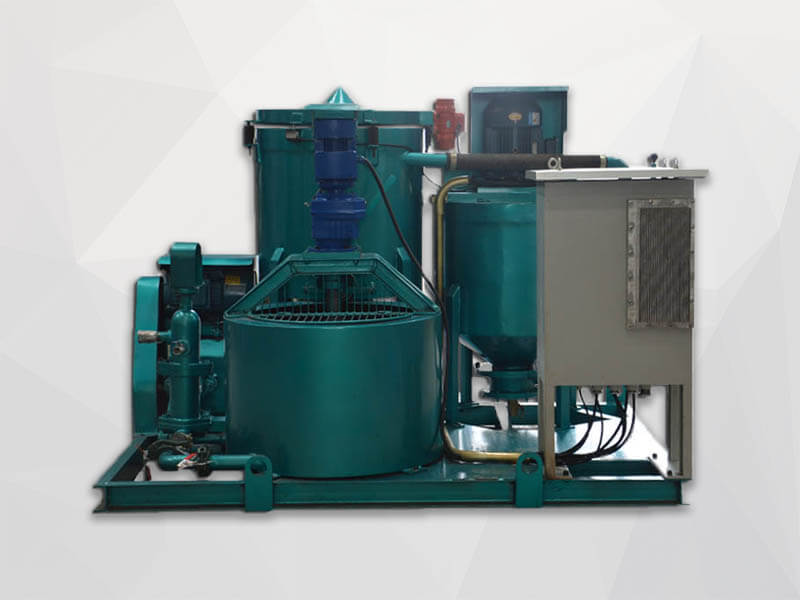

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit -

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale -

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

.jpg)

.jpg)