Your position:

Home > Products > Grout Mixing Plant

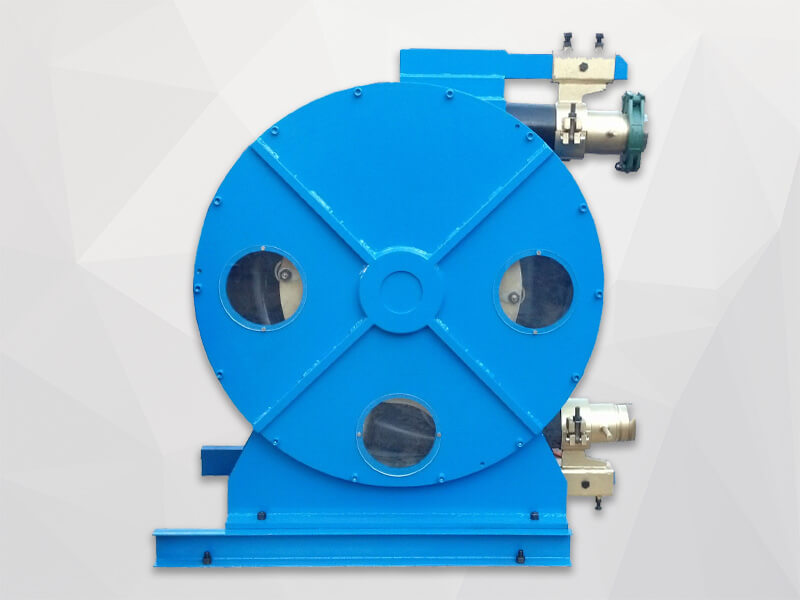

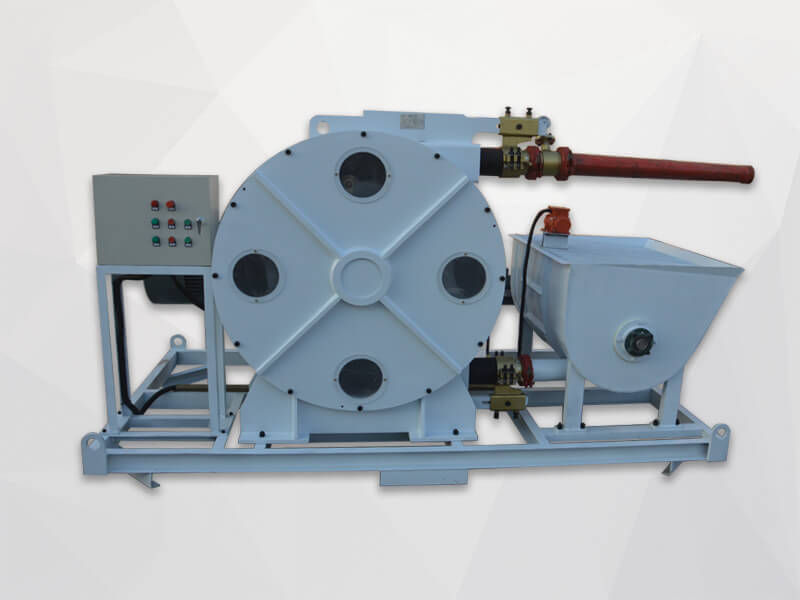

LGP200/300/100PI-D Grout mixing plant for sale

The LGP200/300/100PI-D grout mixing plant is combination with an 200L colloidal mixer, a 300L agitator and hydraulic plunger grout pump in one plant. It is designed to provide a continuous mixing and pumping operation. It is mainly used for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additives.

LGP200/300/100PI-D

200L

4m3/h

1100l/min

0.5 to 1

1450rpm

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

The LGP200/300/100PI-D grout mixing plant is combination with an 200L colloidal mixer, a 300L agitator and hydraulic plunger grout pump in one plant. It is designed to provide a continuous mixing and pumping operation. It is mainly used for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additives. If you want to get our price of grouting mixing plant, you can leave us a message, or send us email to tell me your requirement. Email address: sales1@leadcrete.com

Working principle of grout mixing plant:

Grout mixing plant has special mixing effect of cement or bentonite with water is archived in mixer by a high turbulence created in the pump casing. This turbulence with its high shear forces separates the cement or bentonite particles which results in a fully hydrated suspension.

As soon as the mixing process is over, the mixing is transferred into the agitator. The slow stirring paddle prevents the grout from settling out of suspension and removes any air bubbles from the mix. Each machine incorporates mixers and pumps of matched capacity which together with an agitated storage tank enable virtually continuous operation once work has commenced.

Working principle of grout mixing plant:

Grout mixing plant has special mixing effect of cement or bentonite with water is archived in mixer by a high turbulence created in the pump casing. This turbulence with its high shear forces separates the cement or bentonite particles which results in a fully hydrated suspension.

As soon as the mixing process is over, the mixing is transferred into the agitator. The slow stirring paddle prevents the grout from settling out of suspension and removes any air bubbles from the mix. Each machine incorporates mixers and pumps of matched capacity which together with an agitated storage tank enable virtually continuous operation once work has commenced.

Application

1. Grout mixing plant unit for tunnel lining, contact grouting, shaft waterproofing.

2. Grout mixing plant for dam foundations, tunnels, mining, soil nails, tiebacks, earth anchors, cable and rock bolts.

3. Grout mixing station for underwater foundations, piers, breakers, shoreline foundations.

4. Grout plant unit for pavement under sealing, slab jacking and slab raising.

5. Grout plant unit for pavement under sealing, slab jacking and slab raising.

6. Grout unit for encasements, waterproofing, slope line grouting.

7. Grout mixing plant for deep well casing, monitor wells, well sealing and abandonment.

8. Acted as a grouting mixing plant in the pipe jacking machine for building and bridge restoration, foundation stabilization, foundation raising, soil compaction grouting, soil & rock grouting.

2. Grout mixing plant for dam foundations, tunnels, mining, soil nails, tiebacks, earth anchors, cable and rock bolts.

3. Grout mixing station for underwater foundations, piers, breakers, shoreline foundations.

4. Grout plant unit for pavement under sealing, slab jacking and slab raising.

5. Grout plant unit for pavement under sealing, slab jacking and slab raising.

6. Grout unit for encasements, waterproofing, slope line grouting.

7. Grout mixing plant for deep well casing, monitor wells, well sealing and abandonment.

8. Acted as a grouting mixing plant in the pipe jacking machine for building and bridge restoration, foundation stabilization, foundation raising, soil compaction grouting, soil & rock grouting.

Features

1. All components of LGP200/300/100PI-D grout mixing plantare easily accessible for operating, cleaning and maintenance.

2. Grout plant for sale with best price and ISO, CE certificate.

3. Butterfly valve of mixer and agitator.

4. Operator controls are centrally located for efficient production.

5. Yuken relief valve and directional valve for hydraulic system of grout pump.

6. Oil temperature gauge can automatically control cooler fan working in normal temperature rang, if temperature is too high, the grout plant unit will stop work automatically.

7. Compact size, it is combination with an 200L colloidal mixer, a 300L agitator and hydraulic plunger grout pump in one base frame.

2. Grout plant for sale with best price and ISO, CE certificate.

3. Butterfly valve of mixer and agitator.

4. Operator controls are centrally located for efficient production.

5. Yuken relief valve and directional valve for hydraulic system of grout pump.

6. Oil temperature gauge can automatically control cooler fan working in normal temperature rang, if temperature is too high, the grout plant unit will stop work automatically.

7. Compact size, it is combination with an 200L colloidal mixer, a 300L agitator and hydraulic plunger grout pump in one base frame.

Technical Parameters

| Description | Data |

| Grout mixing plant type | LGP200/300/100PI-D |

| Mixer Volume | 200L |

| Mixer production(w/c ratio=1) | 4m3/h |

| Circulation capacity | 1100l/min |

| Suitable W/C Ratio | 0.5 to 1 |

| Mixer hydraulic motor | 1450rpm |

| Agitator Volume | 300L |

| Agitator hydraulic motor speed | 36rpm |

| Water tank | 60L |

| Grout Pump Type | LGH90 |

| Grout pump output(Max.) | 100L/min |

| Grout pump work pressure | 10MPa |

| Deutz F3L912 diesel | 34kw, 2200rpm |

| Grout Station Overall dimension | 4130x1850x2500mm |

| Grout Station Weight | 2795kg |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station -

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit -

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale -

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

.jpg)

.jpg)