Your position:

Home > Products > Refractory Pan Mixer

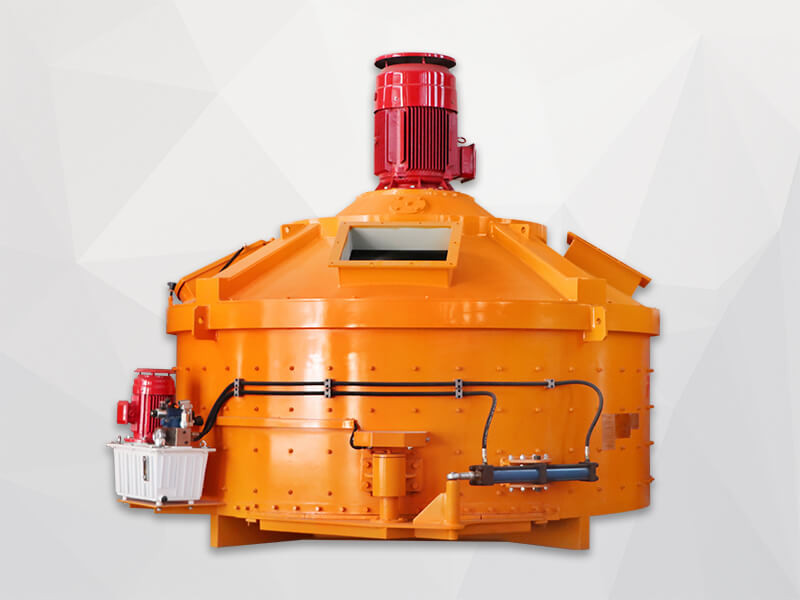

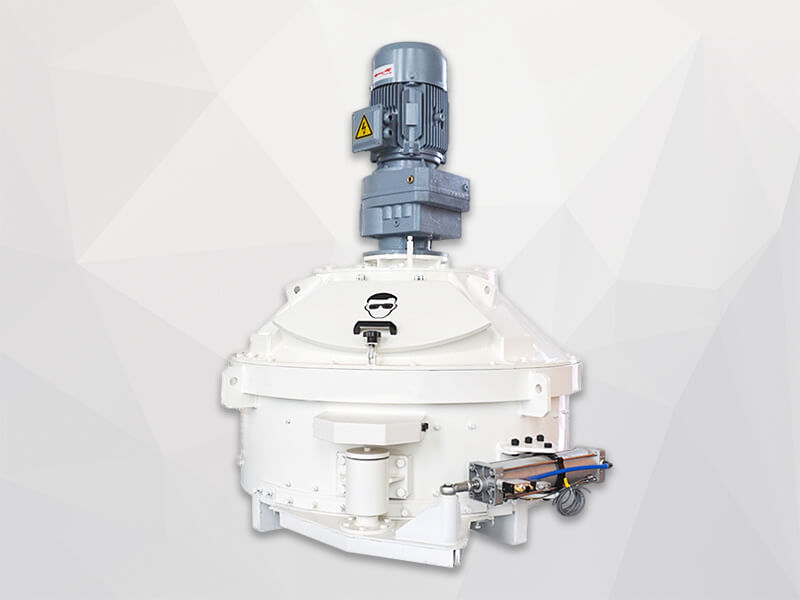

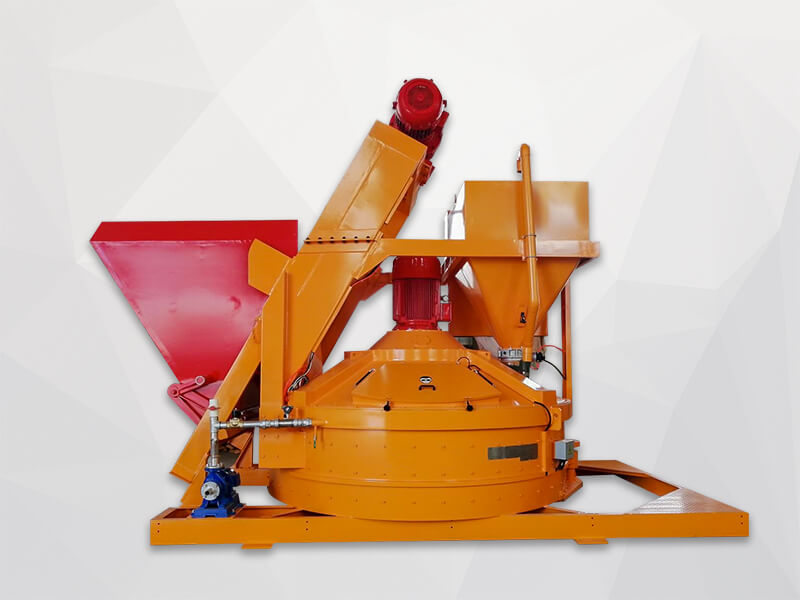

LCPM Counter Current Planetary Concrete Mixer

LCPM Counter Current Planetary Concrete Mixer are exported to dozens of countries and regions such as the United States, Russia, Dubai, Brazil, Vietnam, and Thailand.

LCPM750

1125

1800

750

30

1*3

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

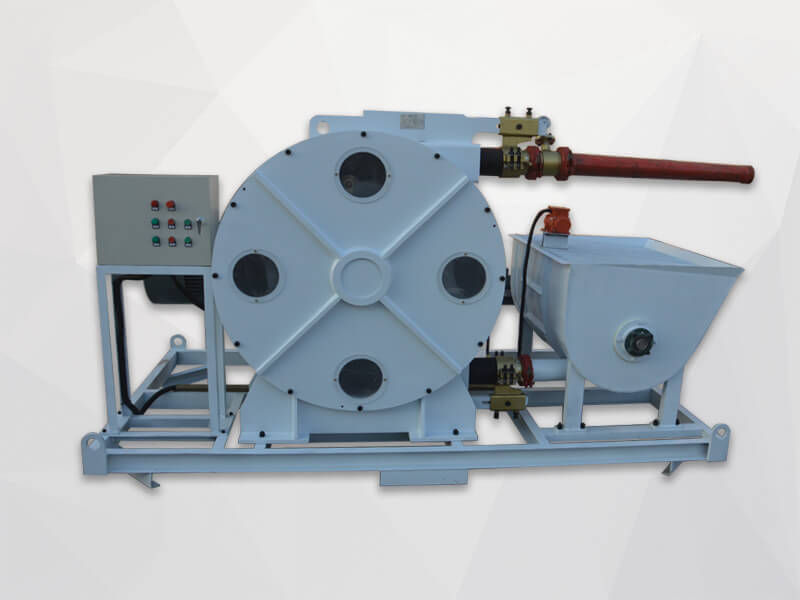

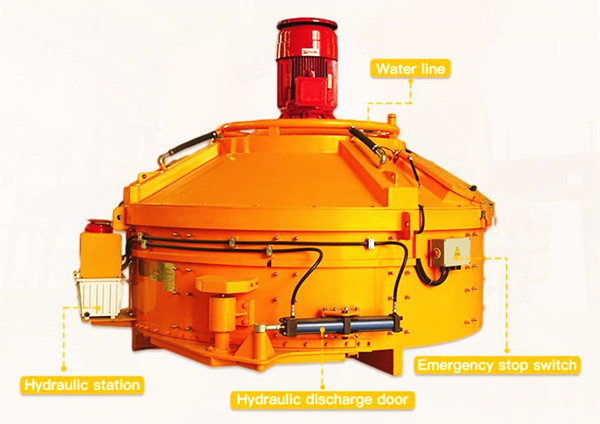

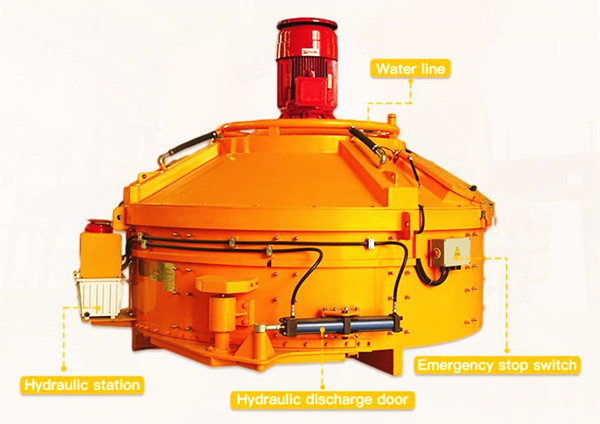

LCPM counter-current planetary mixer can mix all kinds of high-quality and high-performance concrete to achieve uniform mixing in the shortest time. The mixing effect is better. This is the so-called planetary mixing. There is no dead angle at 360 degrees. It is several grades higher than the ordinary mixer. Wider range of use.

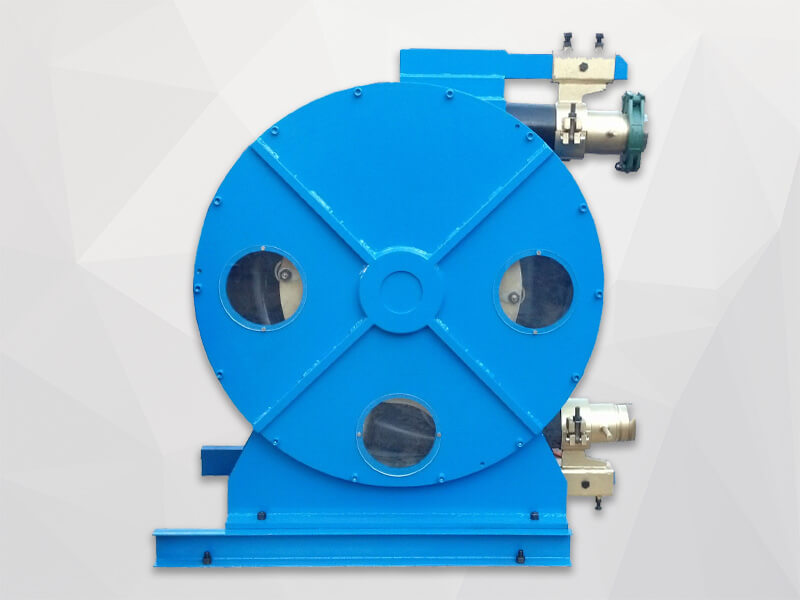

Counter-current gearing system of counter current planetary concrete mixer:

The rotation direction of hybrid stars is opposite to the revolution direction, and the direction of each hybrid star is also different. Circular motion and convective motion make the materials fully mixed to achieve uniform distribution.

Convective mixing device of planetary concrete mixer:

★ high mixing efficiency and low energy consumption.

★ compared with the traditional planetary mixer, the mixing time of LCPM can be reduced by 15 ~ 20%.

★ the no-load current and load current of the same material can be reduced by 15 ~ 20%.

Options of counter current planetary mixer:

Hydraulic coupling (Italy).

Humidity probe (Germany).

High pressure washout system (Italy).

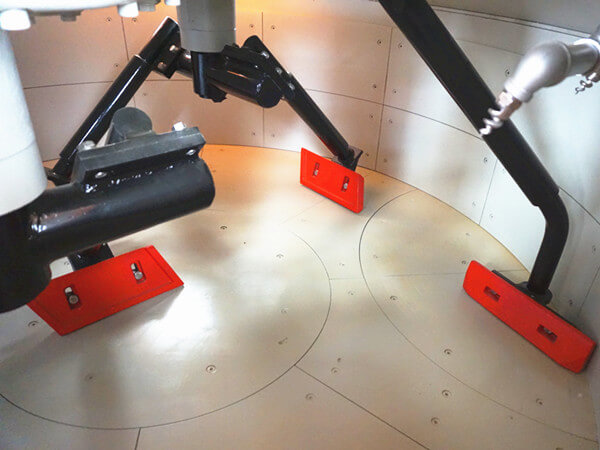

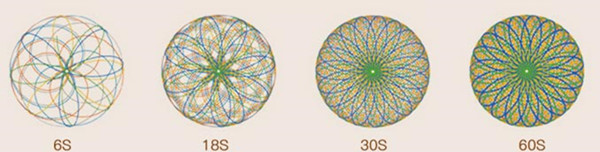

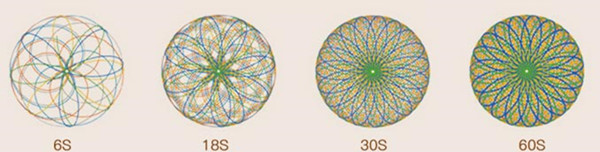

Mixing Locus Diagrams of concrete planetary mixer:The diagram shows the perfect mixing action of the counter-current planetary mixer from 6 to 60 seconds after materials are added. Note that the floor is completely swept by the mixing star s action every 4 revolutions (6 seconds) and that each zone is covered at regular intervals in time.

Counter-current gearing system of counter current planetary concrete mixer:

The rotation direction of hybrid stars is opposite to the revolution direction, and the direction of each hybrid star is also different. Circular motion and convective motion make the materials fully mixed to achieve uniform distribution.

Convective mixing device of planetary concrete mixer:

★ high mixing efficiency and low energy consumption.

★ compared with the traditional planetary mixer, the mixing time of LCPM can be reduced by 15 ~ 20%.

★ the no-load current and load current of the same material can be reduced by 15 ~ 20%.

Options of counter current planetary mixer:

Hydraulic coupling (Italy).

Humidity probe (Germany).

High pressure washout system (Italy).

Mixing Locus Diagrams of concrete planetary mixer:

Application

LCPM Counter Current Planetary Concrete Mixer can also be widely used for glass, ceramics, refractories, fertilizer and concrete, etc. We can offer customized counter current planetary mixer for special requirements or applications.

| Concrete | Other Construction Material | Refractory Materials | Others |

| Ready-mixed Concrete | Dry Mortar | Shaped refractory | Glass |

| Precast Concrete | Wet Mortar | Unshaped refractory | Fertilizer |

| Foam Concrete | Gypsum | Water treatment | |

| Color Concrete | Aggregate Mixing | Mine backfill | |

| Light Concrete | Emulsified asphalt | ||

| Shotcrete | Cement adhesive |

Features

Features of LCPM counter current planetary concrete mixer:

1. Compact structure and small space required;

2. Simple structure, simple and convenient maintenance;

3. Lower energy consumption, high homogenization, short mixing time;

4. Flexible layout, 1~3 unloading doors are optional for different production lines.

Leadcrete Equipment company advantage:

1. We are a countercurrent planetary mixer factory, not a trading company. This means that we can better control production and communicate with customers in time.

2. We have an excellent team to serve you. Top design team, sales team, production team, transportation team and after-sales team.

3. We can provide special designs for different requirements. For example, some customers do not have enough space to accommodate all machines, so we can make special design and provide the best solution.

4. Confirm with the customer before the concrete mixer is produced. Make sure all the details are correct.

1. Compact structure and small space required;

2. Simple structure, simple and convenient maintenance;

3. Lower energy consumption, high homogenization, short mixing time;

4. Flexible layout, 1~3 unloading doors are optional for different production lines.

Leadcrete Equipment company advantage:

1. We are a countercurrent planetary mixer factory, not a trading company. This means that we can better control production and communicate with customers in time.

2. We have an excellent team to serve you. Top design team, sales team, production team, transportation team and after-sales team.

3. We can provide special designs for different requirements. For example, some customers do not have enough space to accommodate all machines, so we can make special design and provide the best solution.

4. Confirm with the customer before the concrete mixer is produced. Make sure all the details are correct.

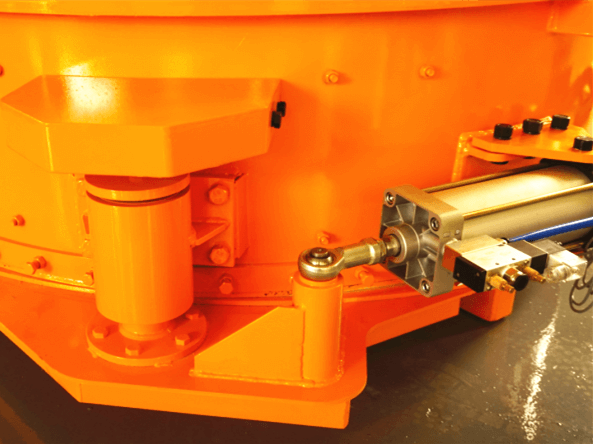

Product Details

-

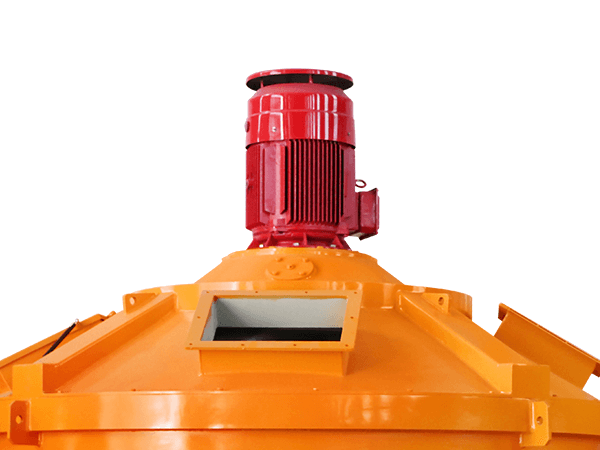

Mixing device: Driven by the gearing system, the blades fixed on mixing arms and the scarpers arms crush and overturn the: material to complete the compelling mixing.

-

Observing port: You can observe boring operation without turning off the machine.

-

Hydraulic power unit: A specially designed hydraulic power unit is adopted to provide power for multiple discharge doors. In case of emergency, these discharge doors can be opened by hand.

-

Mixing device: Driven by the transmission system, the blade and scraper arm fixed on the mixing arm crush and turn the material over: the material completes forced mixing.

-

Water spray pipe: Specially designed sprayers are installed on water pipes. Sprayed water clouds can cover more areas or mix.

-

Discharging door: The discharge door is equipped with discharge switch, which can conveniently set the size of the door according to the need.

Technical Parameters

Technical Data

| Item | LCPM50 | LCPM100 | LCPM150 | LCPM250 | LCPM330 | LCPM500 | LCPM750 | LCPM1000 | LCPM1250 |

| Feeding Volume (L) | 75 | 150 | 225 | 375 | 500 | 750 | 1125 | 1500 | 1875 |

| Feeding Capacity (Kg) | 120 | 240 | 360 | 600 | 790 | 1200 | 1800 | 2400 | 3000 |

| Output Volume (L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 | 1000 | 1250 |

| Mixing Power (Kw) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 | 45 |

| Mixing Star*Blade | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*3 | 1*3 | 2*3 | 2*3 |

| Side Scraper | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Discharge Scraper | - | - | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Discharging Power (KW) | Pneumatic Discharging | 2.2 | 2.23 | 2.2 | 3 | 3 | 3 | ||

| Weight (Kg) | 750 | 1000 | 1300 | 1500 | 2000 | 2400 | 3900 | 5500 | 6000 |

| Item | LCPM1500 | LCPM2000 | LCPM2500 | LCPM3000 |

| Feeding Volume (L) | 2250 | 3000 | 3750 | 4500 |

| Feeding Capacity (Kg) | 3600 | 4800 | 6000 | 7250 |

| Output Volume (L) | 1500 | 2000 | 2500 | 3000 |

| Mixing Power (Kw) | 55 | 75 | 90 | 110 |

| Mixing Star*Blade | 2*3 | 3*3 | 3*3 | 3*3 |

| Side Scraper | 1 | 1 | 1 | 1 |

| Discharge Scraper | 1 | 2 | 2 | 2 |

| Discharging Power (Kw) | 3 | 4 | 4 | 4 |

| Weight (Kg) | 6500 | 9200 | 11000 | 12000 |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LRM refractory castable mixers are designed by refractory castable mixer manufacturer Lead Equipment for mixing refractory materials, castable materials, etc.LRM 100kg 250kg 500kg Refractory Castable Pan Mixer

LRM refractory castable mixers are designed by refractory castable mixer manufacturer Lead Equipment for mixing refractory materials, castable materials, etc.LRM 100kg 250kg 500kg Refractory Castable Pan Mixer -

LRM800 refractory mixer machine for sale is the most efficient and productive mixer for refractory castables. It is reinforced with bolt in high wear resistance steel drum liners, making the refractory pan mixer the most durable refractory mixers on the market.LRM800 Refractory Mixer Machine For Sale

LRM800 refractory mixer machine for sale is the most efficient and productive mixer for refractory castables. It is reinforced with bolt in high wear resistance steel drum liners, making the refractory pan mixer the most durable refractory mixers on the market.LRM800 Refractory Mixer Machine For Sale -

LRM1000 refractory pan mixer is a refractory pan mixer supplier Lead Equipment Co., Ltd. which is specially designed for mixing refractory materials, castables, etc.LRM1000 1000kg Mixing Capacity Refractory Pan Mixer

LRM1000 refractory pan mixer is a refractory pan mixer supplier Lead Equipment Co., Ltd. which is specially designed for mixing refractory materials, castables, etc.LRM1000 1000kg Mixing Capacity Refractory Pan Mixer -

LCPM Hydraulic / pneumatic discharge planetary concrete mixer is not only for mixing concrete, it also can be applied to glass ceramics, refractories, and other industries.LCPM Hydraulic / pneumatic discharge planetary concrete mixer

LCPM Hydraulic / pneumatic discharge planetary concrete mixer is not only for mixing concrete, it also can be applied to glass ceramics, refractories, and other industries.LCPM Hydraulic / pneumatic discharge planetary concrete mixer

.jpg)

.jpg)