Your position:

Home > Products > Grout Mixing Plant

LGP500/700/100PI-E Tunnel lining grout plant

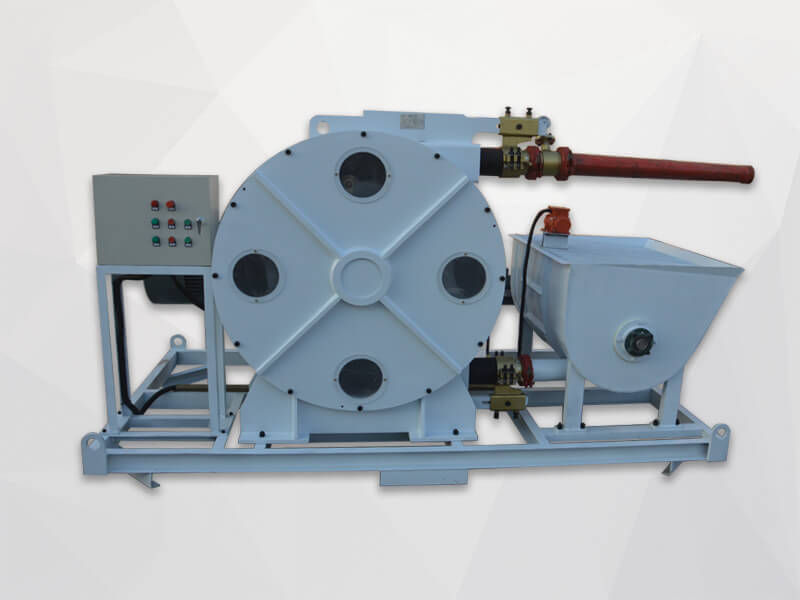

LGP500/700/100PI-E tunnel lining grout plant is a whole unit of grouting and mixing, it consists of a mixing tank,an agitator tank and a high-pressure hydraulic grouting pump. LGP500/700/100PI-E grout mixing plant for TBM is applied for making the cement grout slurry and then grouting the slurry under high pressure.

LGP500/700/100PI-E

500L

7m3/h

700L

0-100L/min

0-5MPa

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LGP500/700/100PI-E tunnel lining grout plant is a whole unit of grouting and mixing, it consists of a mixing tank,an agitator tank and a high-pressure hydraulic grouting pump. LGP500/700/100PI-E grout mixing plant for TBM is applied for making the cement grout slurry and then grouting the slurry under high pressure. High speed vortex mixer ensures mix quickly and evenly. Water, cement and other media are quickly mixed into homogeneous slurry. Then the mixed slurry is delivered to the grout agitator. Grout pump injects from the mixing drum (storage tank). This ensures a continuous mixing and grouting operations. The grouting pump of our LGP500/700/100PI-E grout plant for tunnel lining is hydraulic drive. Grouting pressure and displacement is stepless adjustable. This LGP500/700/100PI-E grouting plant has the advantages of simple structure, reliable work performance, high efficient slurry-making, high pumping pressure, etc. The grouting output of the plant can be adjusted continuously and the max. work pressure can be adjusted continuously, too.

Application

1. Grouting plant for civil engineering - dam, tunnel, subway, mine, soil nailing wall, curtain, anchor, cable trench and anchor grouting.

2. Grout plant for building structure - building and bridge repair, foundation reinforcement, slope support, soil compaction, terrg grouting.

3. Grout mixing plant for engineering - underwater foundation, offshore platform, coast foundation grouting reinforcement.

4. Grout unit for mine application - roadway reinforcement, backfill, waterproof grouting.

2. Grout plant for building structure - building and bridge repair, foundation reinforcement, slope support, soil compaction, terrg grouting.

3. Grout mixing plant for engineering - underwater foundation, offshore platform, coast foundation grouting reinforcement.

4. Grout unit for mine application - roadway reinforcement, backfill, waterproof grouting.

Features

1. High speed vortex mixer ensures mix quickly and evenly.

2. Grouting pressure, displacement can be stepless adjustable.

3. Our tunnel lining grout plant is with CE, ISO certification.

4. Compact size and LGP500/700/100PI-E Tunnel lining grout plant is easy to operate. It also takes up a small space.

5. Grouting plant for tunnels is simple structure, light weight, easy maintenance.

6. The motor has an overload protection function. Hydraulic system with oil temperature overheating protection.

7. This grout unit has less spare parts ensure low maintenance costs.

8. Mixer and agitator of plant switch by using squeeze handle, it is safe, reliable and easy to operate.

9. Our grouting plant has double grouting cylinder, continuous output with small pulse.

10. Electrical control box manufactured by thicker plate and standard. Schneider electrical elements.

2. Grouting pressure, displacement can be stepless adjustable.

3. Our tunnel lining grout plant is with CE, ISO certification.

4. Compact size and LGP500/700/100PI-E Tunnel lining grout plant is easy to operate. It also takes up a small space.

5. Grouting plant for tunnels is simple structure, light weight, easy maintenance.

6. The motor has an overload protection function. Hydraulic system with oil temperature overheating protection.

7. This grout unit has less spare parts ensure low maintenance costs.

8. Mixer and agitator of plant switch by using squeeze handle, it is safe, reliable and easy to operate.

9. Our grouting plant has double grouting cylinder, continuous output with small pulse.

10. Electrical control box manufactured by thicker plate and standard. Schneider electrical elements.

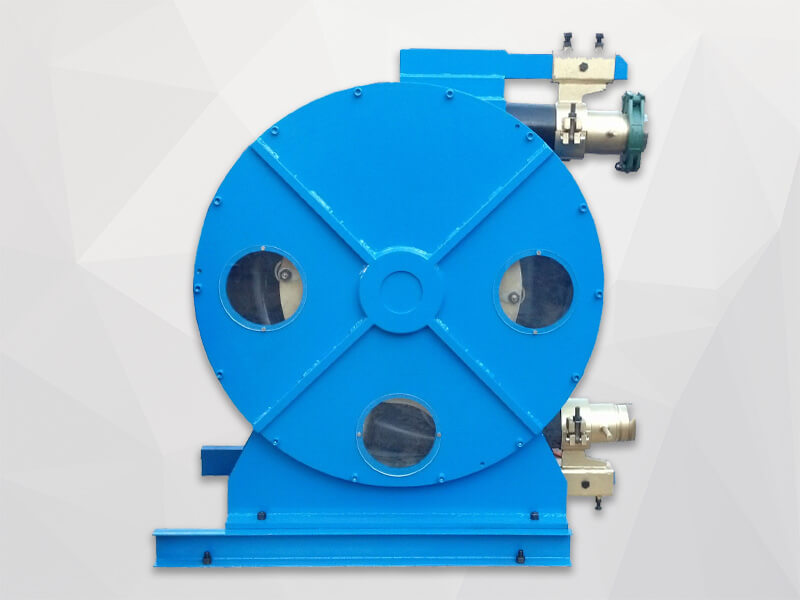

Product Details

Technical Parameters

Technical Data

| Description | Data |

| Grouting plant for tunnels model | LGP500/700/100PI-E |

| Dimensions | 2700×1750×1650mm |

| Weight | 1440kg |

| Mixer | |

| Capacity | 500L |

| Output | 7m3/h |

| Power | 7.5Kw, 1450rpm,50Hz,380V |

| Rated Rev | 1450rpm |

| W/C ratio | ≥0.5:1 |

| Agitator | |

| Capacity | 700L |

| Rated Rev. | 36rpm |

| Power | 1.5KW, 50Hz,380V |

| Pump | |

| Output | 0-100L/min |

| Pressure | 0-5MPa |

| Power | 15kw,50Hz,380V |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station -

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit -

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale -

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

.jpg)

.jpg)