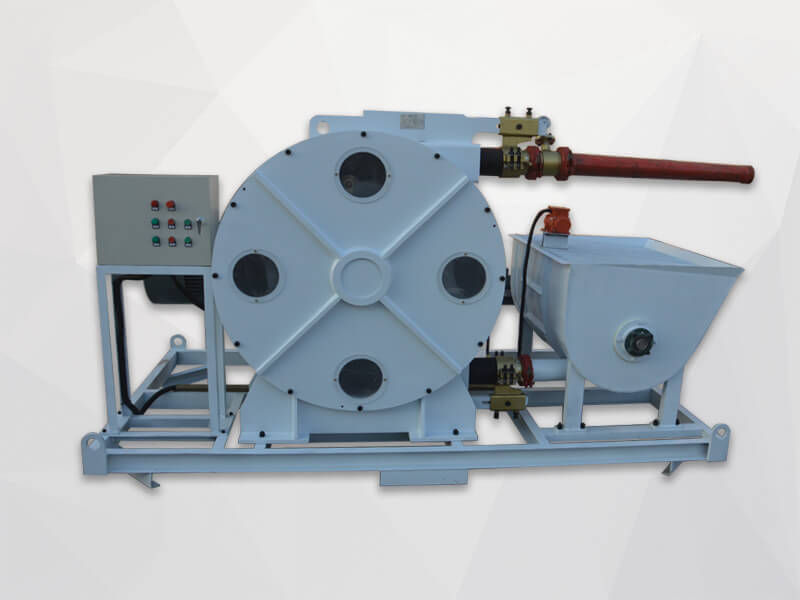

LZ-9E/S Pea gravel backfilling machine installation on TBM has reliable high conveying performance and outstanding quality properties. Compared with the traditional spraying and conveying machine, it has several advantages: hydraulic floating compression (pressure automatic compensation after the rubber sealing plate is worn), hydraulic turning hopper house, hydraulic lifting rotor body, automatic anti-blocking function, rubber seal plate automatic lubrication, the locally control mode and remote control function with PLC control system, which greatly enhance the degree of automation of the machine and increase the machine efficiency.

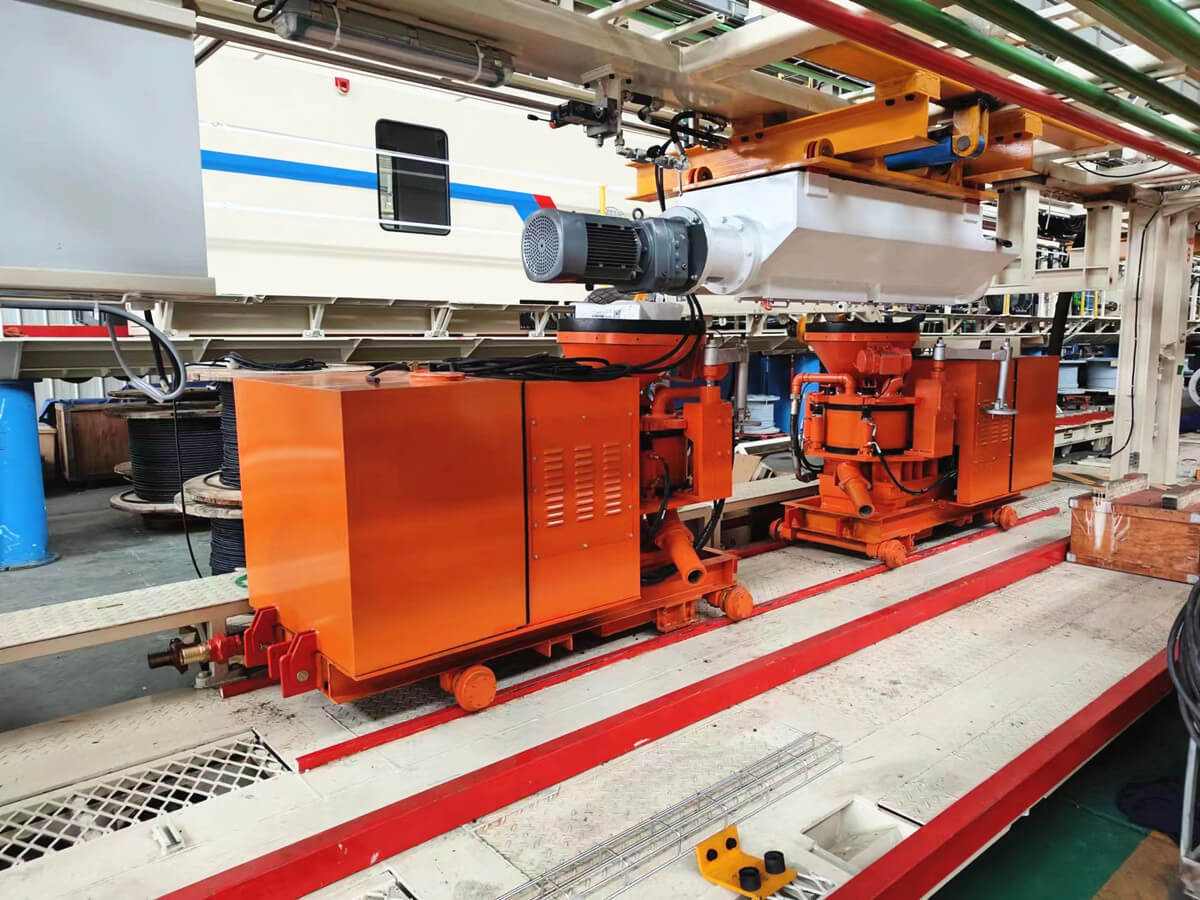

Pea gravel shotcrete pump system for backfilling pea gravel installation on China Railway TBM:

Finally LZ-9E/S Rotary machine for pea gravel backfilling is widely adopted for the pneumatic conveyance of pea-gravel when tunnelling with a TBM. LZ-9E/S is also widely used in mines, tunnels, culverts, subways, hydropower projects, underground projects, etc.

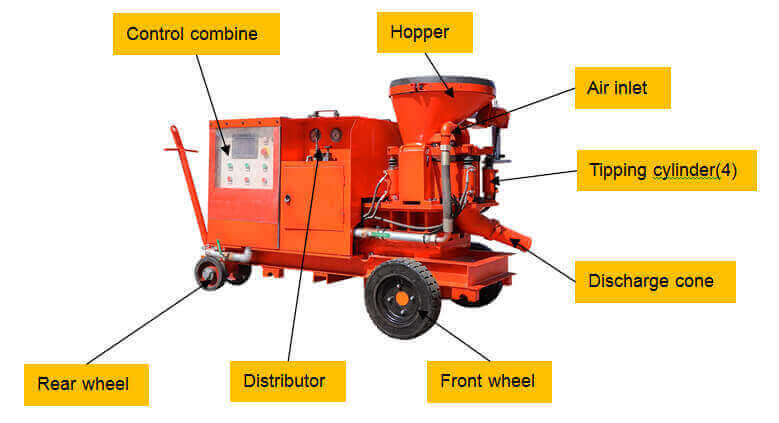

1. Control system

Variable output with variable-frequency drive.

PLC integrated machine control.

Locally control mode and remote control function.

2. Hydraulic system

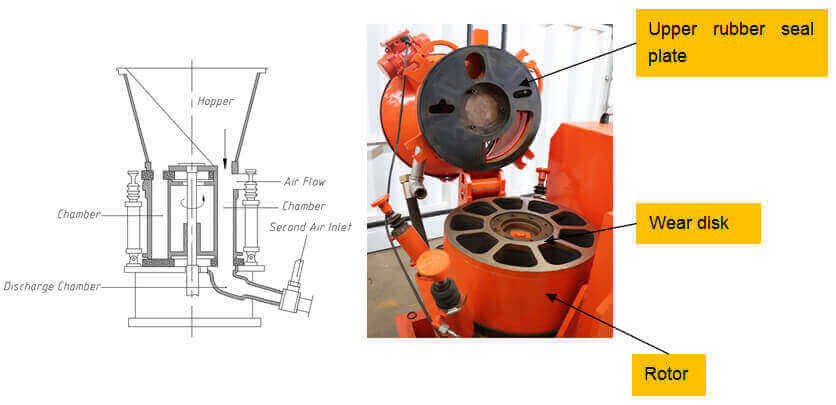

Hydraulic floating compression (pressure automatic compensation after the rubber sealing plate is worn).

Hydraulic lifting rotor body.

3. Intelligent anti-clogging pipe system

4. Automatic lubrication

Automatic lubrication for upper and lower seal plates.

5. Sector rigid wear plate and rotor

6. High quality upper and lower rubber seal plates

7. Wheels

Heavy-duty solid wheels.

Steerable rear wheels.

Solid wheels can be replaced with track wheels as needed.

|

Specification (with Electric motor drive): |

||

|

1. Automatically clean delivery line blockage: PLC+VFD+Air Pressure Sensor. |

||

|

Rotor Volume |

12.9L |

|

|

Max. Rotor Speed |

12.6r/min |

|

|

Max. Output ① |

9.5m³/h |

|

|

Max. Horizontal Conveying Distance |

200m |

|

|

Max. Aggregate Size |

Φ20 mm |

|

|

Conveying Hose Inner Diameter |

64mm |

|

|

Operating Air Pressure |

0.2-0.4MPa(29-58PSI) |

|

|

Air Consumption |

12-14m³/min(215-250CFM) |

|

|

Rotor Motor |

Power |

7.5kW |

|

Voltage |

3 phase, 380V, 50Hz |

|

|

Hydraulic System |

Power |

0.37Kw |

|

Voltage |

3 phase, 380V, 50Hz |

|

|

Automatic Lubrication |

Volume |

4L |

|

Power |

24V, 50w |

|

|

Vibration Motor |

Power |

0.04Kw |

|

Voltage |

3 phase, 380V, 50Hz |

|

|

Dimension(L×W×H) (heavy-duty solid wheels) |

2200×960×1300mm |

|

|

Weight(heavy-duty solid wheels) |

1425kg |

|

|

①Data is based on safe filling and complete emptying of the cylinder. |

||

|

We could also customize according to your demands. |

||

-

LZ-9 9m3/h shotcrete machine is a large pneumatic shotcrete machine. The output can reach 9m3 / h, the maximum transmission distance can reach 200m, stable performance, simple operation, and reasonable price, so it is widely used in large-section tunnels, mining operations, hydropower projects and hillside protection.LZ-9 Shotcrete machine

LZ-9 9m3/h shotcrete machine is a large pneumatic shotcrete machine. The output can reach 9m3 / h, the maximum transmission distance can reach 200m, stable performance, simple operation, and reasonable price, so it is widely used in large-section tunnels, mining operations, hydropower projects and hillside protection.LZ-9 Shotcrete machine -

LSZ3000 shotcrete machine for sale is a universal concrete spraying machine for the processing of wet or dry mix. LSZ3000 shotcrete machine for sale due to its full pneumatic driven unit. for the required anti-explosion applications, such as coal mining, tunnel and underground engineering. This unit is specially equipped for LSZ3000 shotcrete machine, which is powerful and versatile.LSZ3000 Wet shotcrete machine for sale

LSZ3000 shotcrete machine for sale is a universal concrete spraying machine for the processing of wet or dry mix. LSZ3000 shotcrete machine for sale due to its full pneumatic driven unit. for the required anti-explosion applications, such as coal mining, tunnel and underground engineering. This unit is specially equipped for LSZ3000 shotcrete machine, which is powerful and versatile.LSZ3000 Wet shotcrete machine for sale -

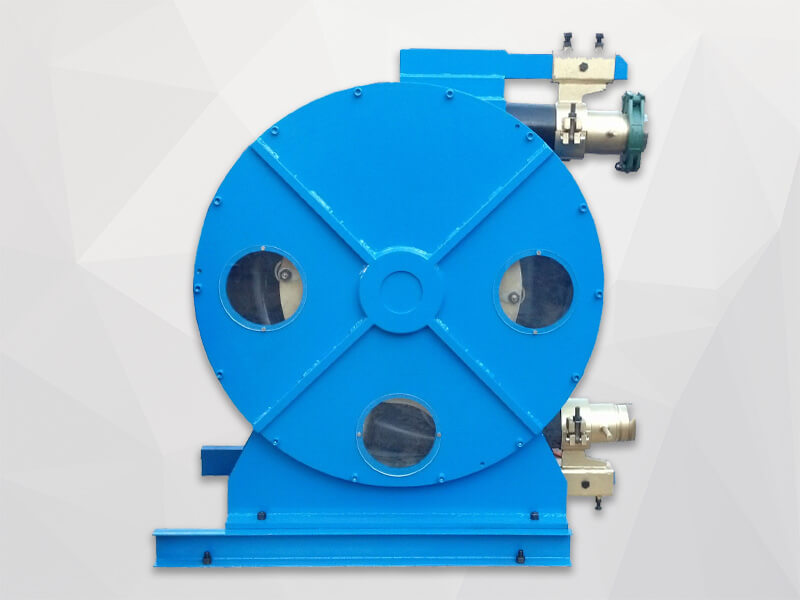

LPS-7A wet shotcrete machine for sale use hydraulic pumping S valve structure, two oil cylinders Reciprocating motion alternately to pump concrete from conveying pipe to nozzle, Add compress air to wet shotcrete machine outlet and add A percentage of the accelerator at nozzle, concrete slurry be sprayed to surface directly.LPS-7A Wet shotcrete machine

LPS-7A wet shotcrete machine for sale use hydraulic pumping S valve structure, two oil cylinders Reciprocating motion alternately to pump concrete from conveying pipe to nozzle, Add compress air to wet shotcrete machine outlet and add A percentage of the accelerator at nozzle, concrete slurry be sprayed to surface directly.LPS-7A Wet shotcrete machine -

LZ-5 gunite machine for sale is a dry gunite machine with an output of 5m3 / h and a maximum acceptable size of 15mm. It is widely used in dams, mines, tunnels, culverts, subways, hydropower projects, underground Engineering, slope reinforcement, etc.LZ-5 Gunite machine for sale

LZ-5 gunite machine for sale is a dry gunite machine with an output of 5m3 / h and a maximum acceptable size of 15mm. It is widely used in dams, mines, tunnels, culverts, subways, hydropower projects, underground Engineering, slope reinforcement, etc.LZ-5 Gunite machine for sale

.jpg)

.jpg)

.jpg)