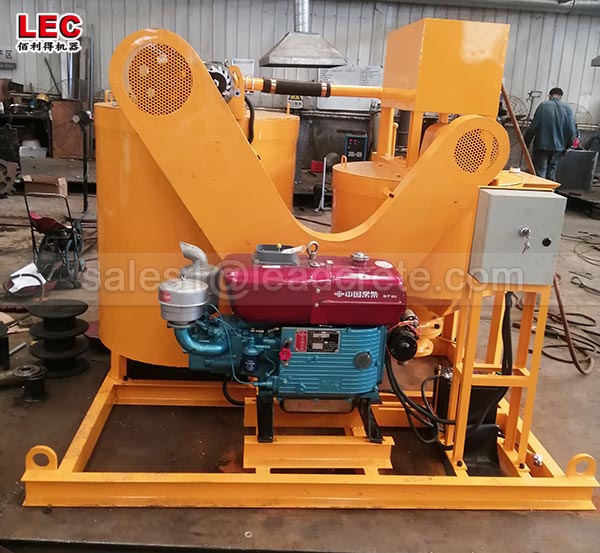

Automatic Grout Batching Mixing Station

Automatic Grout Batching Mixing Station is an intelligent equipment integrating material storage, metering, mixing and transportation. It is widely used in engineering fields such as foundation treatment, tunnel construction, and mine grouting.

An Automatic Grout Mixing Station is an advanced piece of equipment designed to automate the process of preparing grout mixtures for various construction and engineering applications.

Automatic Grout Batching Mixing Station is mainly conceived to obtain, through a high turbulence mixing of water and cement powder, a cement mixture (cement grout), or, by using water and bentonite powder, a bentonite slurry for plastic mud. Also the preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components (for every screw conveyor).

Applications

Tunneling and Microtunneling: For stabilizing the excavation face and transporting cuttings in tunnel boring machine (TBM) operations.

Pipe Jacking: Provides lubricating slurries to reduce friction between the pipe and soil during jacking.

Geotechnical Engineering: Used for soil stabilization, grouting, and diaphragm wall construction.

Mining: For backfilling and ground support in underground mining operations.

Civil Infrastructure: Used in the construction of dams, foundations, and retaining walls for grout injection.