Your position:

Home > Products > Grout Mixing Plant

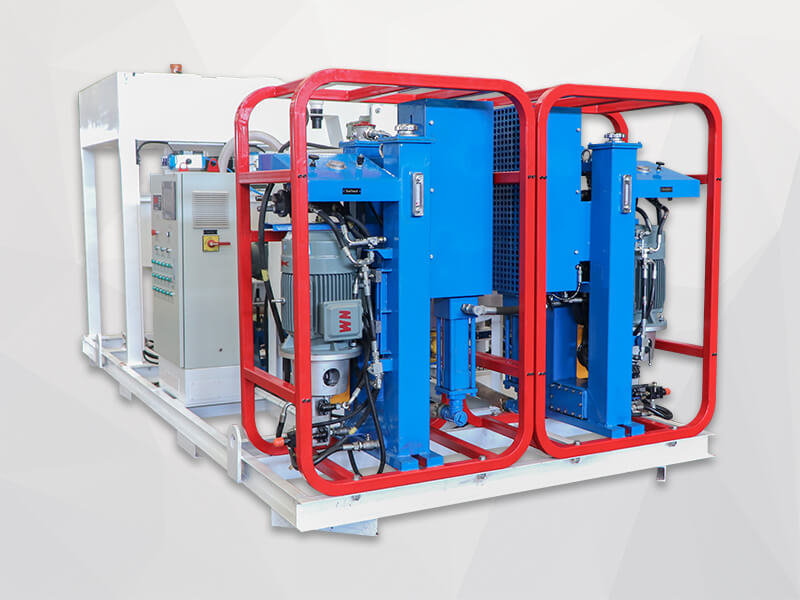

LGP1200/1200/2X75/100PI-E Automated mix and grout plant

Automated mixing and grouting plants for colloidal mixing and injection of suspensions for a range of different applications as well.

LGP1200/1200/2X75/100PI-E

0.5~1

1200L

1200L

950L

150L

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

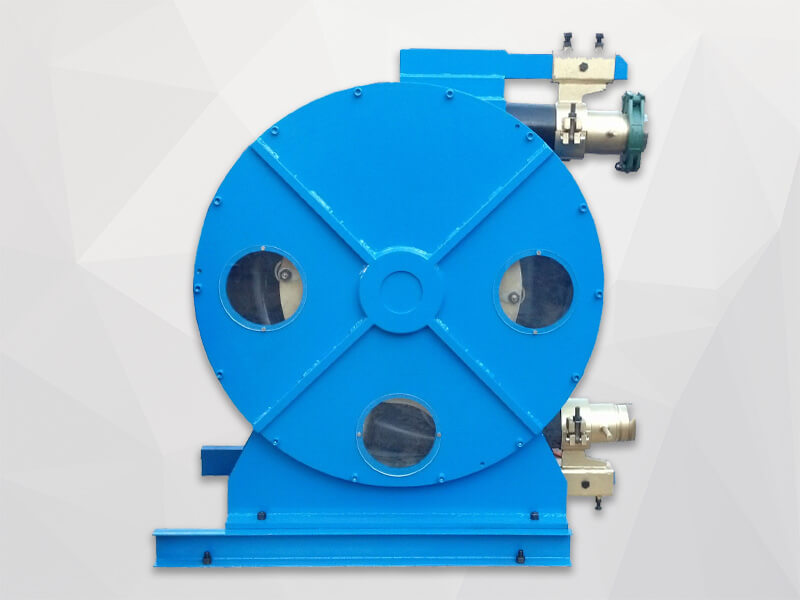

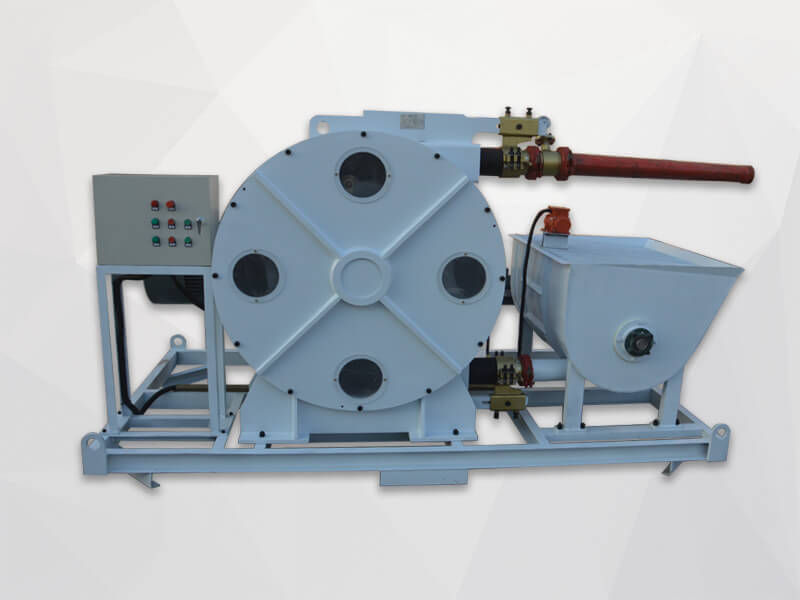

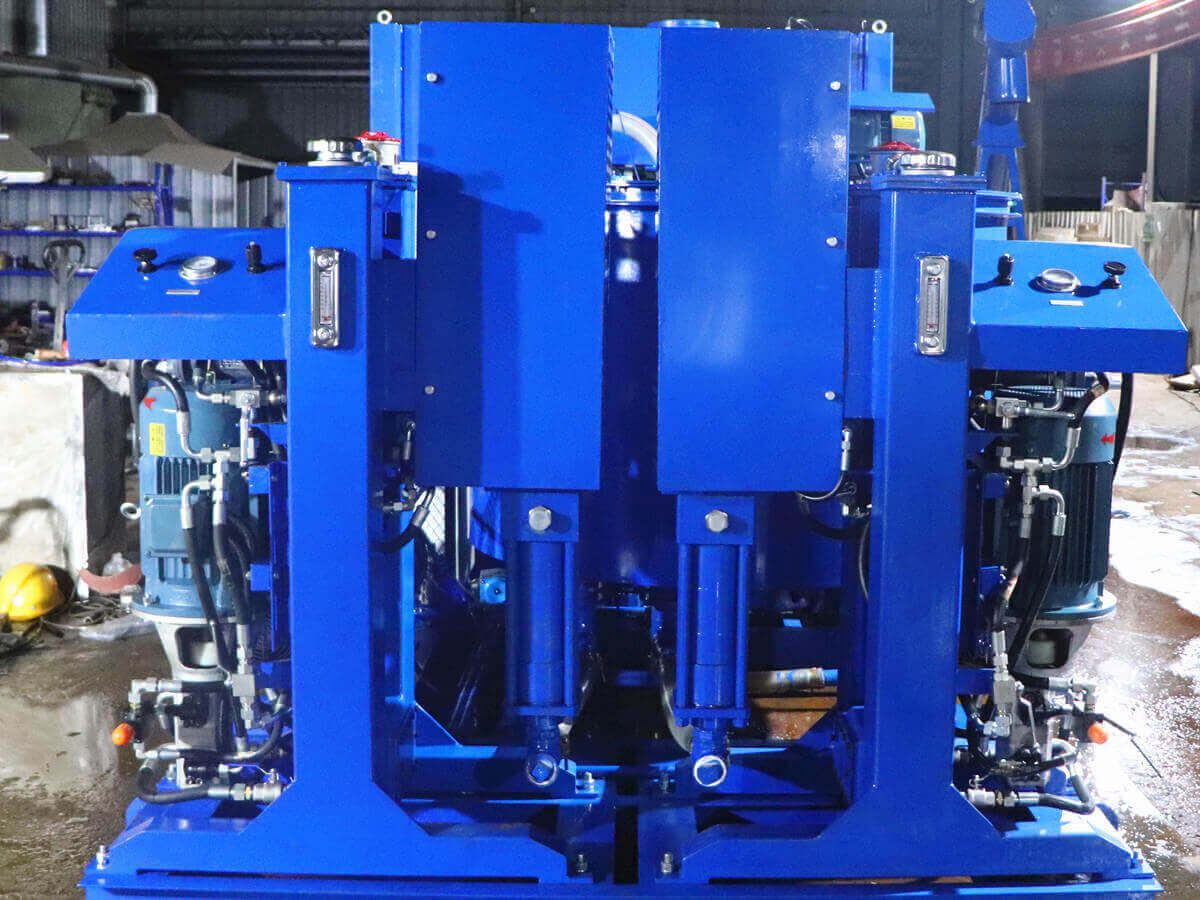

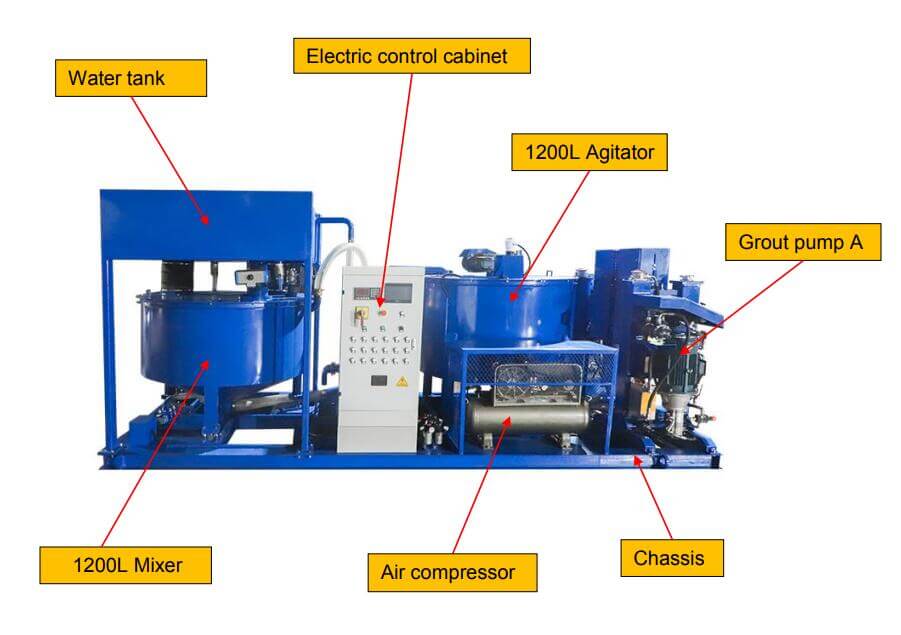

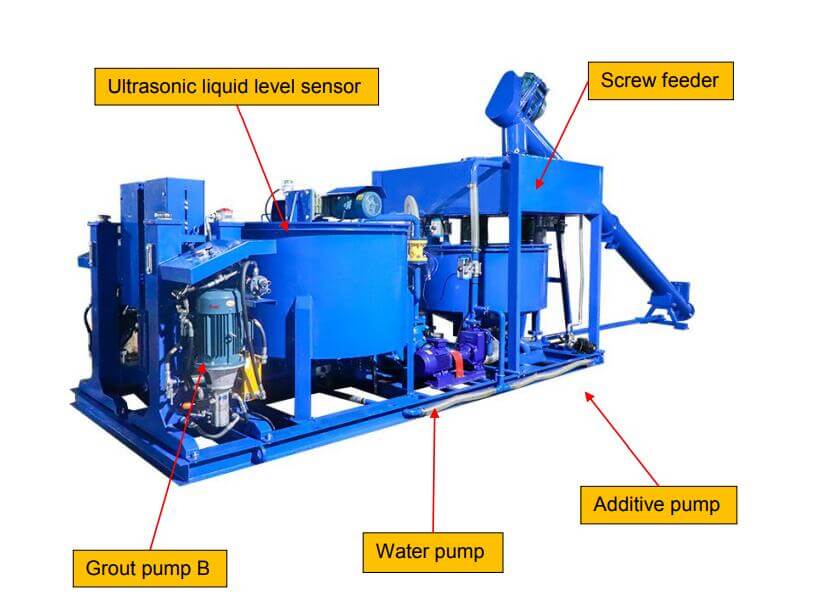

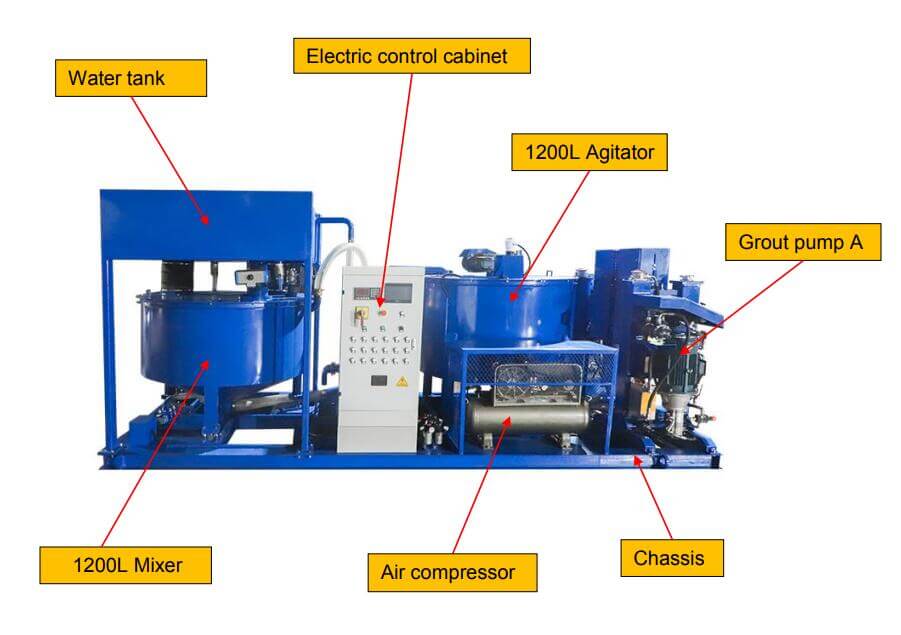

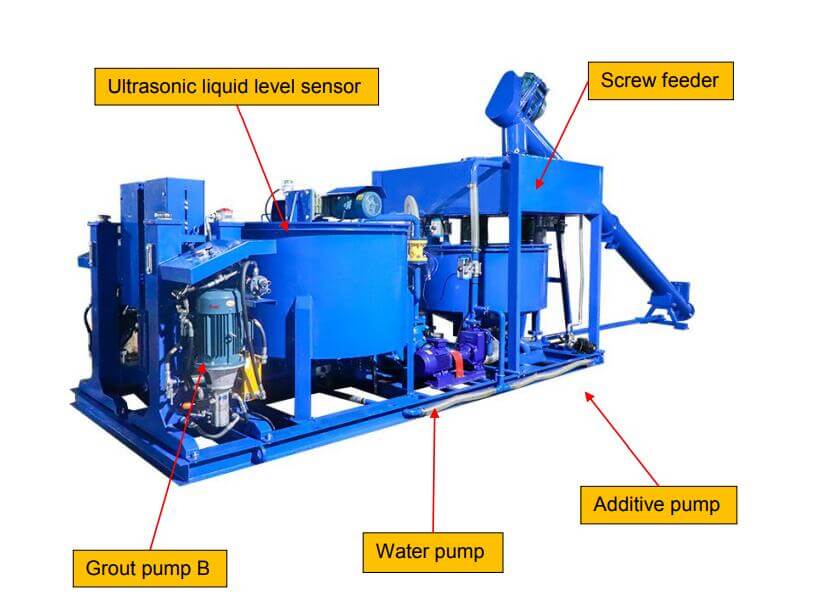

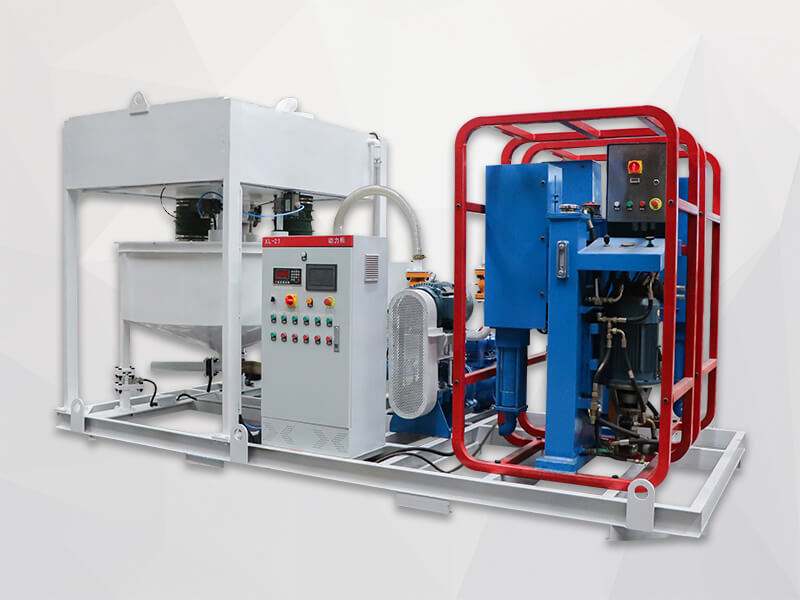

LGP1200/1200/2X75/100PI-E Automated mixing and grouting plant is a combination of a 1200L colloidal batch mixer, a 1200L tank agitator, a circulation pump, a delivery volume 40t/h screw feeder and 2 sets LGH75/100PI-E grouting pumps.

The automated mixing and grouting plants' automatic mode is equipped with an electro-pneumatic system upon loadcells and a PLC that can freely adjust the proportion of water, cement, and additives, and can be set according to the formula of automatic configuration of materials, greatly improving the work efficiency.

The automated mixing and grouting plants' automatic mode is equipped with an electro-pneumatic system upon loadcells and a PLC that can freely adjust the proportion of water, cement, and additives, and can be set according to the formula of automatic configuration of materials, greatly improving the work efficiency.

Application

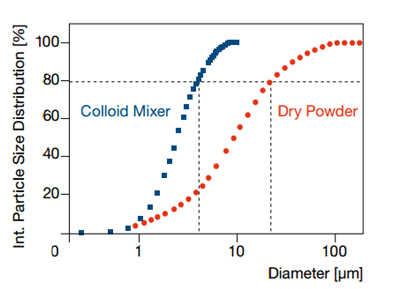

High-speed eddy current mixer ensures fast and even mixing. Water and cement are quickly mixed into a uniform slurry. The grout is then transferred to the grouting pump, which ensures continuous mixing and grout operations.

LGP1200/1200/2X75/100PI-E Automated mixing and grouting plant is mainly used for making cement slurry, etc., which is applied to surface/underground construction, such as hydropower, construction, mining, highway, railway, etc. Possible application areas of LGP1200/1200/2X75/100PI-E Automated mixing and grouting plants are:

Anchor, rock injection

Ground stabilization

Geothermal applications

Well building

Sewer renovation

Sealing grouting

Gap sealing

Contact grouting

Pipe roof grouting

Sleeve pile injection

Backfilling

Cavity filling

Special civil engineering

Seal water sealing

LGP1200/1200/2X75/100PI-E Automated mixing and grouting plant is mainly used for making cement slurry, etc., which is applied to surface/underground construction, such as hydropower, construction, mining, highway, railway, etc. Possible application areas of LGP1200/1200/2X75/100PI-E Automated mixing and grouting plants are:

Anchor, rock injection

Ground stabilization

Geothermal applications

Well building

Sewer renovation

Sealing grouting

Gap sealing

Contact grouting

Pipe roof grouting

Sleeve pile injection

Backfilling

Cavity filling

Special civil engineering

Seal water sealing

Features

1. High speed vortex mixer ensures mix quickly and evenly.

2. There are two operation modes: automatic mode grouting mixing plant and manual mode grouting mixing plant.

3. Automated mixing and grouting plant is with CE, and ISO certification.

4. Mixing and grouting plant has compact structure.

5. Automated grouting plant is simple operation and easy maintenance.

6. Automated mixing plant can realize automatic configuration and replenishment of materials.

7. The proportion of materials in the formula can be adjusted freely.

8. Flameproof electric cabinet, protection grade IP56.

9. Less spare parts ensure low maintenance costs.

More cement grout mixing plants:

2. There are two operation modes: automatic mode grouting mixing plant and manual mode grouting mixing plant.

3. Automated mixing and grouting plant is with CE, and ISO certification.

4. Mixing and grouting plant has compact structure.

5. Automated grouting plant is simple operation and easy maintenance.

6. Automated mixing plant can realize automatic configuration and replenishment of materials.

7. The proportion of materials in the formula can be adjusted freely.

8. Flameproof electric cabinet, protection grade IP56.

9. Less spare parts ensure low maintenance costs.

More cement grout mixing plants:

Product Details

Technical Parameters

Technical Data

| Name | Data | |

| Model | LGP1200/1200/2X75/100PI-E | |

| Mixer | Capacity | 1200L |

| W/C ratio | 0.5~1 | |

| Agitator | Capacity | 1200L |

| Power | 3.0Kw | |

| Circulation pump | Power | 15KW |

| Rate Rev. | 1800r/min | |

| Flow | 850L/min | |

| Screw feeder | Power | 7.5KW |

| Delivery volume | 40t/h | |

| Water supply | Tank capacity | 950L |

| Water pump | 50ZX20-30 (4.0KW) | |

| Flow@head | 20m3/h@30m | |

| Additive supply | Tank capacity | 150L |

| Additive pump | 25SFBX-8 (0.25KW) | |

| Flow@head | 2m3/h@8m | |

| Air Supply | Air compressor | V-0.25/8 (2.2KW) |

| Exhaust volume | 0.25m3/min | |

| Grouting pump | Model | LGH75/100PI-E |

| Piston diameter | 100mm | |

| Piston stroke | 150mm | |

| Low pressure@Flow | 0-50bar@0-75L/min | |

| High pressure@Flow | 0-100bar@0-40L/min | |

| Power | 11Kw | |

| Dimension(without screw feeder) | 4770×2250×2370mm | |

| Weight | 3880Kg | |

| Note: We can customize automated mixing and grouting plants according to your requirements. | ||

case

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

We are high quality automatic grout mixing with pumping equipment supplier and manufactuer from China, if you want to get our grout mixing with pumping equipment quotation or cost, price, you can contact us directly.LGP1000/2X75/100PI-E Automatic grout mixing with pumping equipment

We are high quality automatic grout mixing with pumping equipment supplier and manufactuer from China, if you want to get our grout mixing with pumping equipment quotation or cost, price, you can contact us directly.LGP1000/2X75/100PI-E Automatic grout mixing with pumping equipment -

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station is colloidal type, with high shear high speed, could mixing cement, mortar, water, bentonite etc.LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station is colloidal type, with high shear high speed, could mixing cement, mortar, water, bentonite etc.LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station -

Leadcrete Equipment is one leading diesel engine grout plant manufacturer and supplier from China, if you need our diesel engine grout plant, we would be happy to share price list and details for your reference.LGP400/700/80DPL-D Diesel engine grout plant for sale

Leadcrete Equipment is one leading diesel engine grout plant manufacturer and supplier from China, if you need our diesel engine grout plant, we would be happy to share price list and details for your reference.LGP400/700/80DPL-D Diesel engine grout plant for sale -

Zhengzhou Lead Equipment Co., Ltd. is a leading manufacturer of grout mixer and pump in China. Our LGP550/800/150/70DPL-E Grout pumping station system include many types, as well as an unique supplier with ISO 9001:2008, SGS and CE certificate in below products in China.LGP550/800/150/70DPL-E Grout pumping station system

Zhengzhou Lead Equipment Co., Ltd. is a leading manufacturer of grout mixer and pump in China. Our LGP550/800/150/70DPL-E Grout pumping station system include many types, as well as an unique supplier with ISO 9001:2008, SGS and CE certificate in below products in China.LGP550/800/150/70DPL-E Grout pumping station system

.jpg)

.jpg)